Folding type snow and rain prevention device of sealing-tape machine

A tape machine, folding technology, applied in the direction of conveyor, transportation and packaging, etc., can solve the problems of quality reduction, material moisture content exceeding the standard, feeding and conveying system can not operate normally, to solve the problem of material quality decline, loss avoidance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

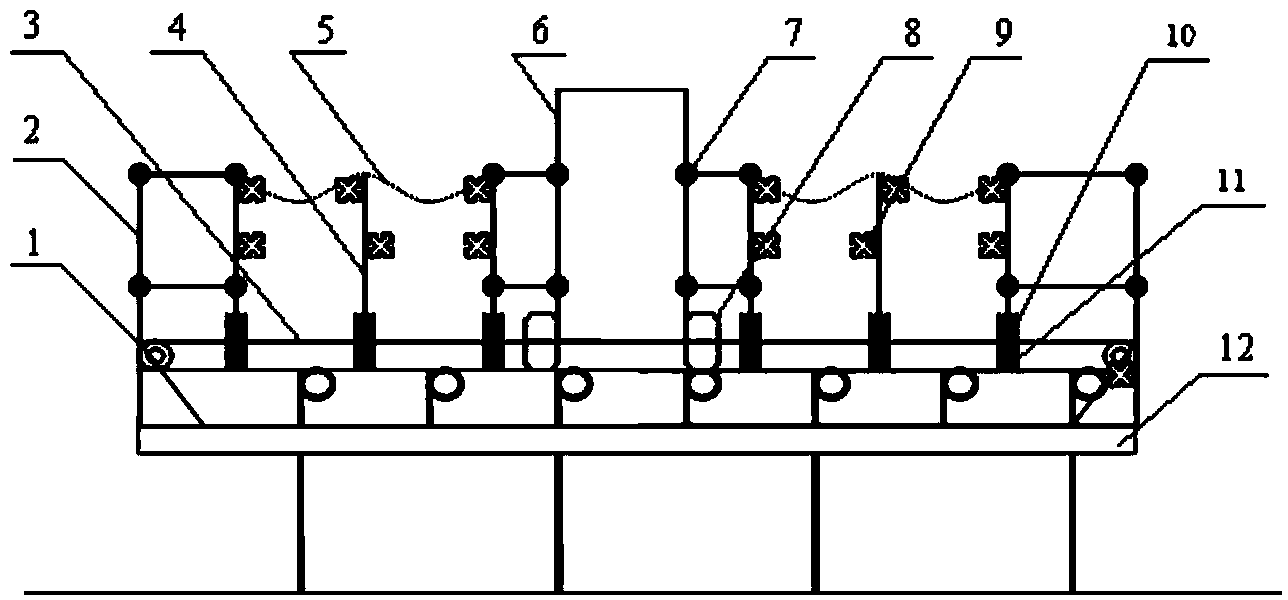

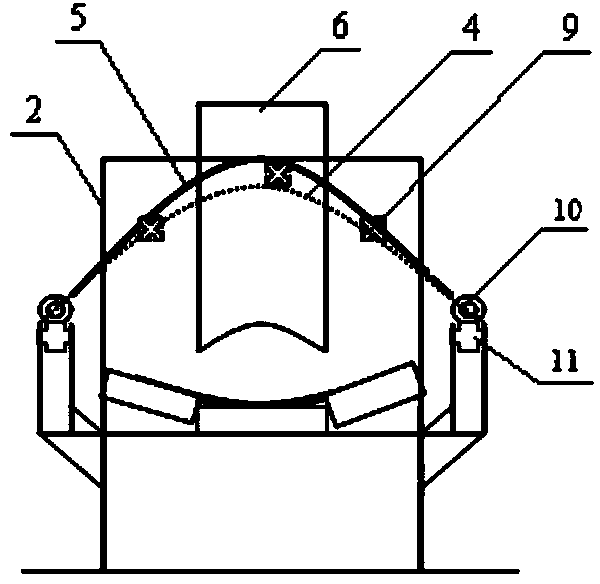

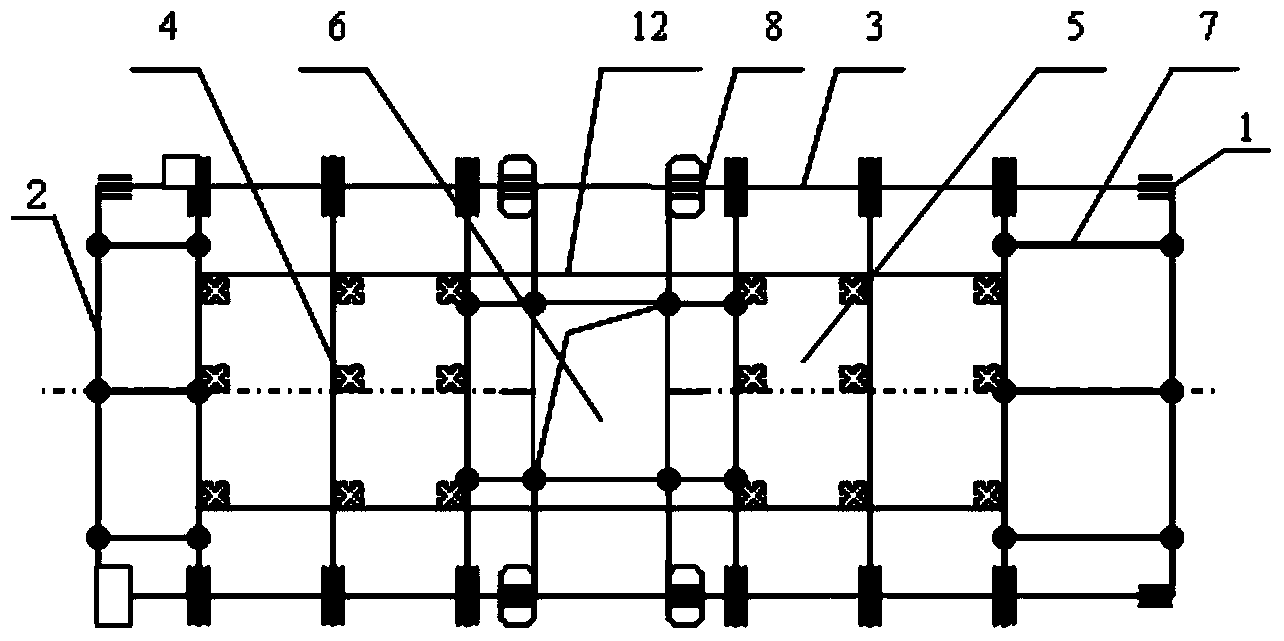

[0014] As can be seen from the accompanying drawings, the belt conveyor folding rain and snow device of the present invention is mainly composed of fixed pulley 1, fixed support 2, steel rope 3, sliding support 4, rainproof cover 5, mobile funnel 6, hinge 7, steel rope locking Device 8, adhesive tape machine stringer 12 are formed.

[0015] The fixed bracket 2 is a frame structure welded by angle steel. Sliding support 4 is the circular arch shape that round steel makes, and the two ends of round steel have an annulus 10 respectively, and circular chute 11 is provided with below annulus 10, and sliding support 4 middle parts are provided with consolidation belt 9. The rainproof cover 5 is made of non-metallic waterproof, tearproof and foldable lightweight material.

[0016] A steel rope locking device 8 is respectively fixed on the two side walls of the lower part of the mobile funnel 6, and two hinges 7 are respectively installed on both sides of the middle part and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com