Electronic element feeding device and application device comprising same

A technology of electronic components and feeding devices, which is applied in the direction of cleaning devices, conveyor objects, transportation and packaging, etc., can solve the problems of increasing the inconvenience of feeding operations, time-consuming elimination of alarms, and increasing the workload of staff, so as to improve the convenience of operation, The effect of preventing material jam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make your examiner further understand the present invention, hereby give a preferred embodiment and cooperate with the drawings, as follows in detail:

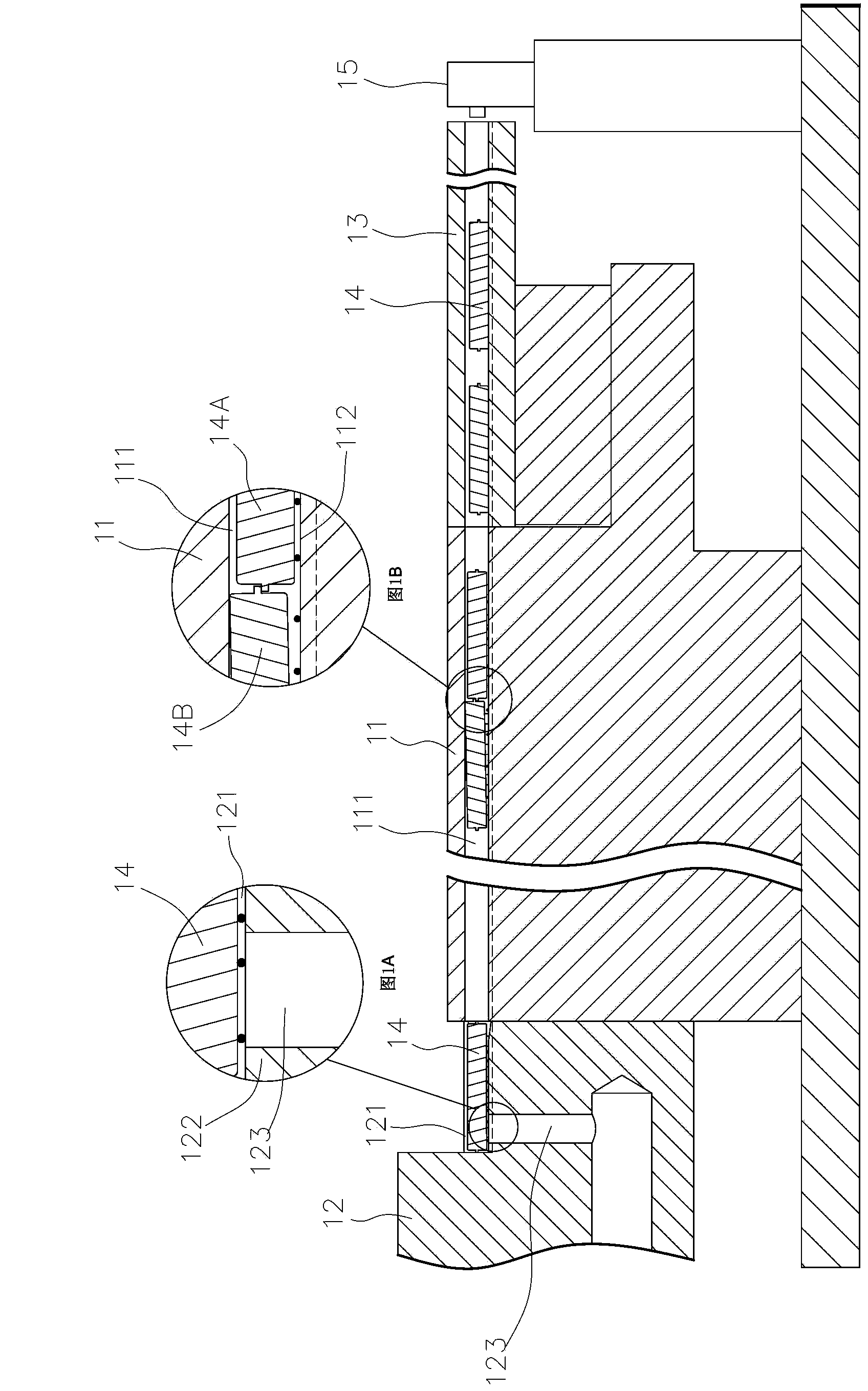

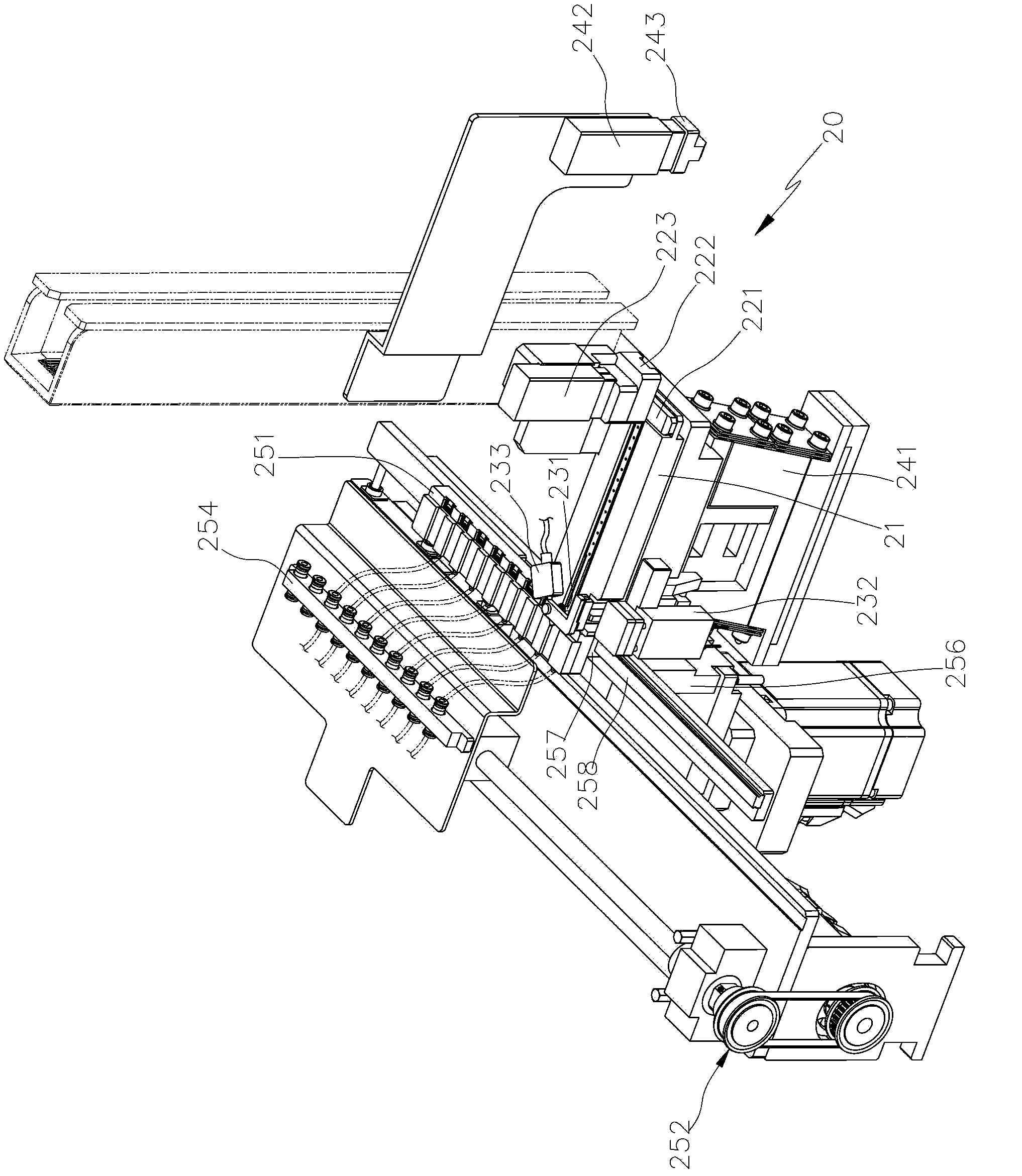

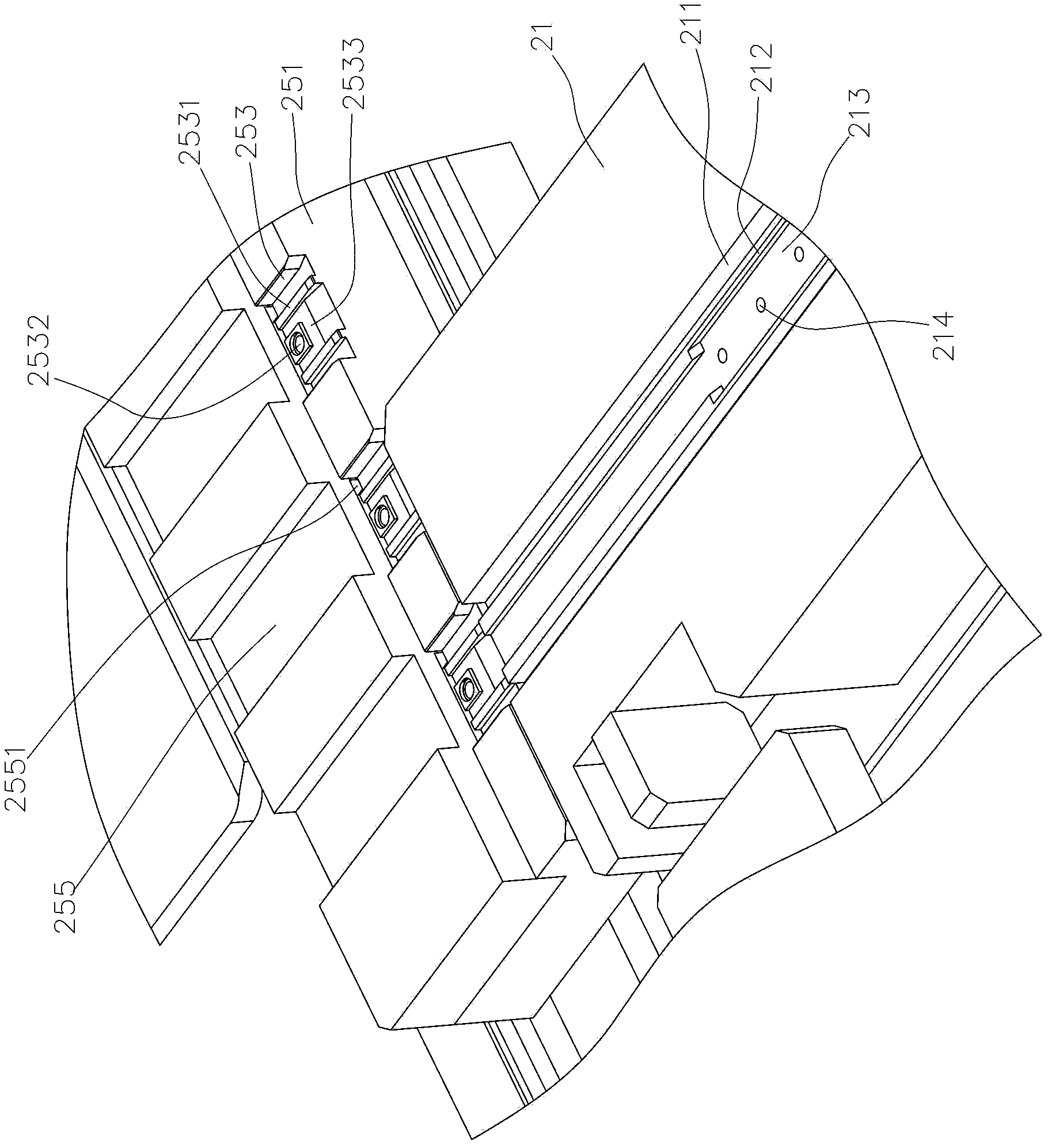

[0051] see figure 2 , image 3 The feeding device 20 of the present invention includes a feeder 21, a positioning mechanism, a limit mechanism, an anti-jamming mechanism, and a loading mechanism. The feeder 21 is provided with at least one material channel 211 that can transport electronic components. In this embodiment, The feeder 21 is placed in the first direction (such as the X direction), and the bottom surface of the feeder 211 is protruded with a bearing portion 212 of appropriate height for holding electronic components. There is an impurity discharge structure that can remove dust and debris. In this embodiment, the impurity discharge structure is provided with a dust discharge channel 213 on the bearing part 212 of the material channel 211, which can allow the dust and debris on the bottom surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com