Drive device for a valve of a beverage filling system

A driving device and filling machine technology, applied in the direction of valve device, valve operation/release device, packaging, etc., can solve the problems of increased probability of failure, excessive energy, inaccurate filling operation, etc., to achieve large Holding force, effect of large switching operation force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

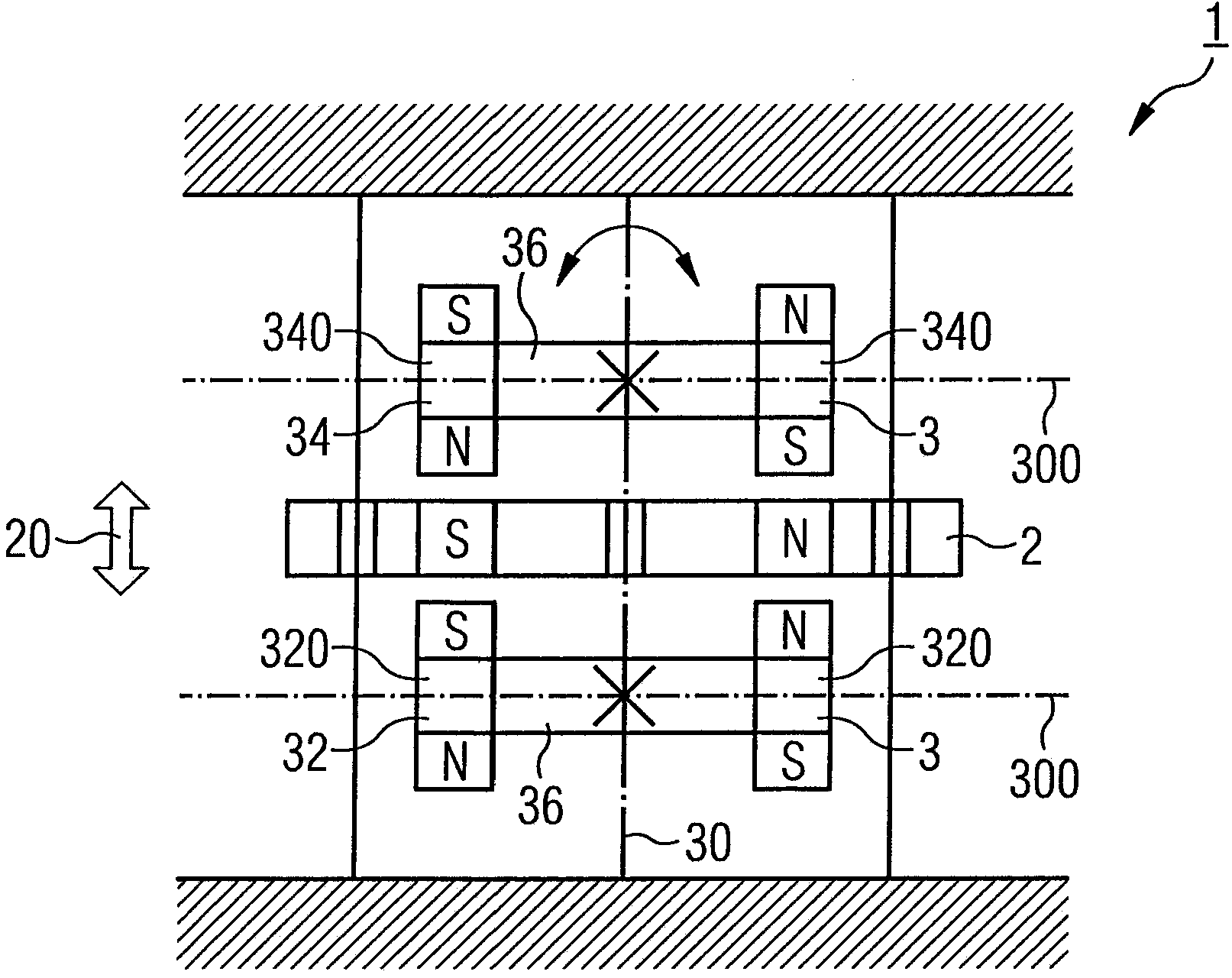

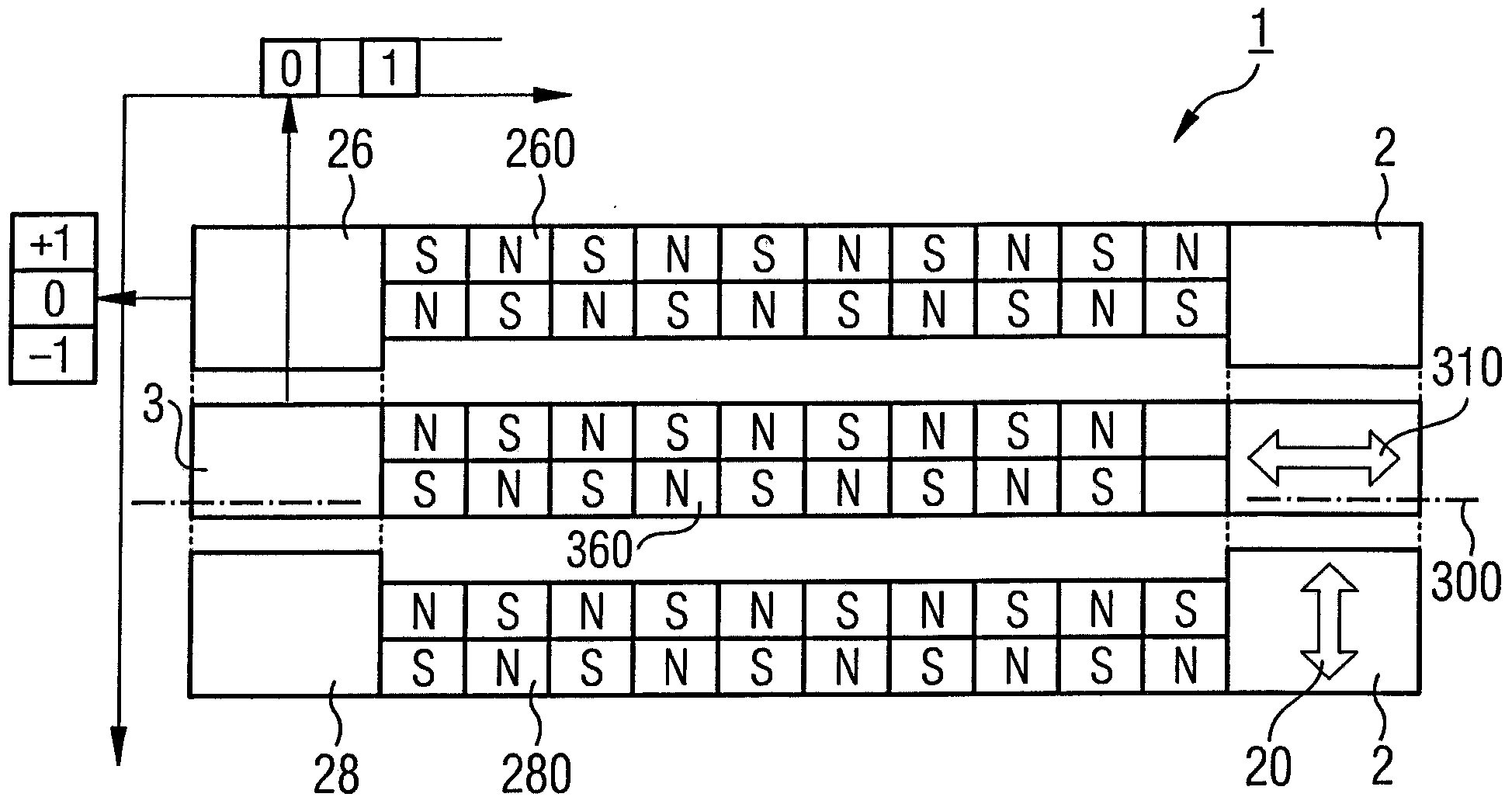

[0032]Preferred embodiments will be described below with reference to the accompanying drawings. Identical, similar or identically functioning components are identified with the same reference numerals in different drawings, and a repeated description of such components is sometimes omitted in the following description to avoid redundancy.

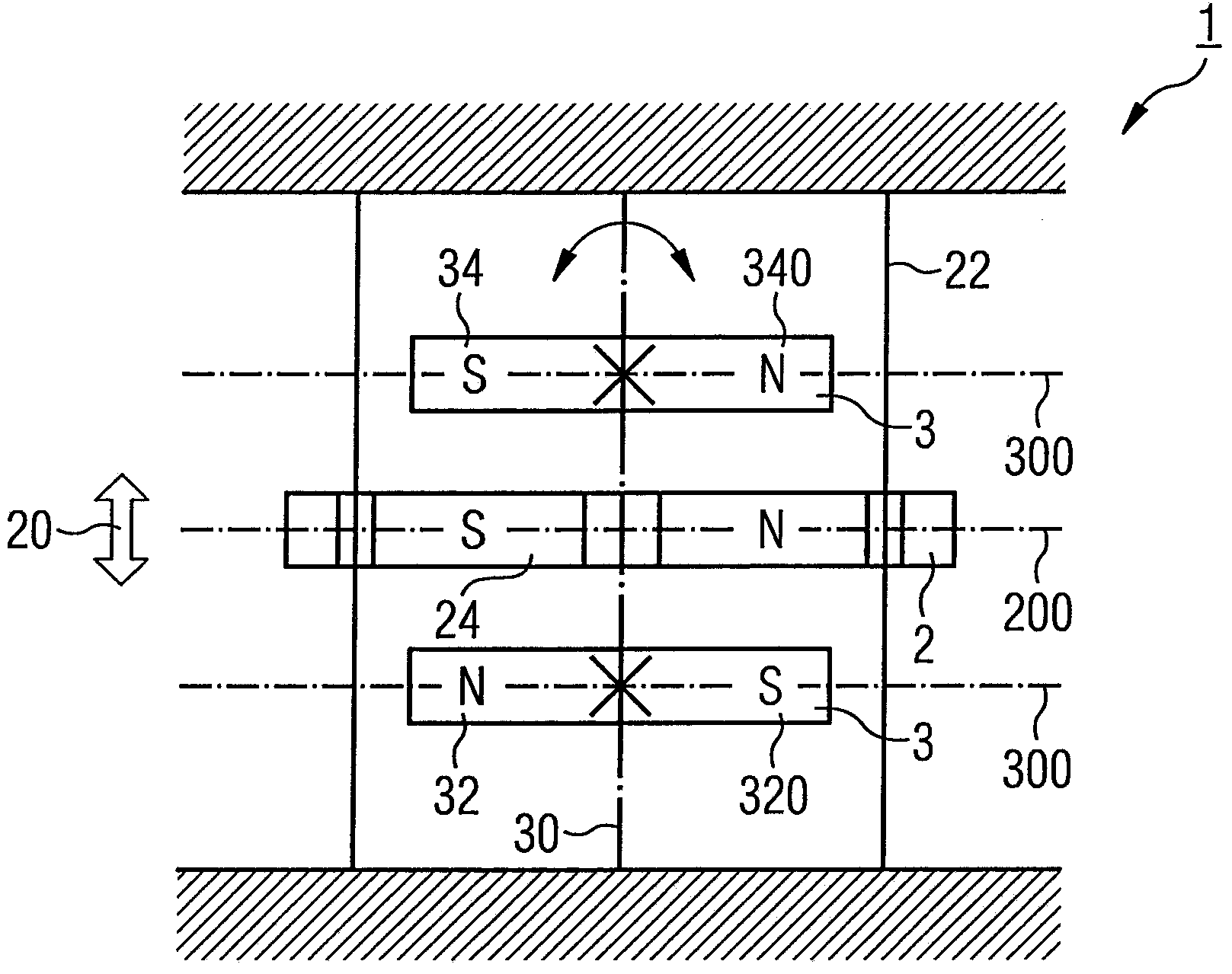

[0033] figure 1 A drive device 1 for a valve of a beverage filling machine is shown, preferably for a material valve and / or a gas valve of a filling mechanism of a beverage filling machine.

[0034] The drive device 1 comprises a movable part 2 which is linearly movable in a direction of movement 20 , the linear movement of which is used to drive the valve. Correspondingly, the movable part 2 can move linearly along the direction of movement 20 indicated by the arrow and is operatively connected to the regulating parts of the valve. in such as figure 1 In the illustrated embodiment, the movable part 2 is correspondingly guided linearly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com