Down feather feeding pipe

A technology of down-filling tube and inner sleeve is applied in the field of down-filling tube, which can solve the problem of inability to prevent the backflow of down, and achieve the effect of preventing backflow of down.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

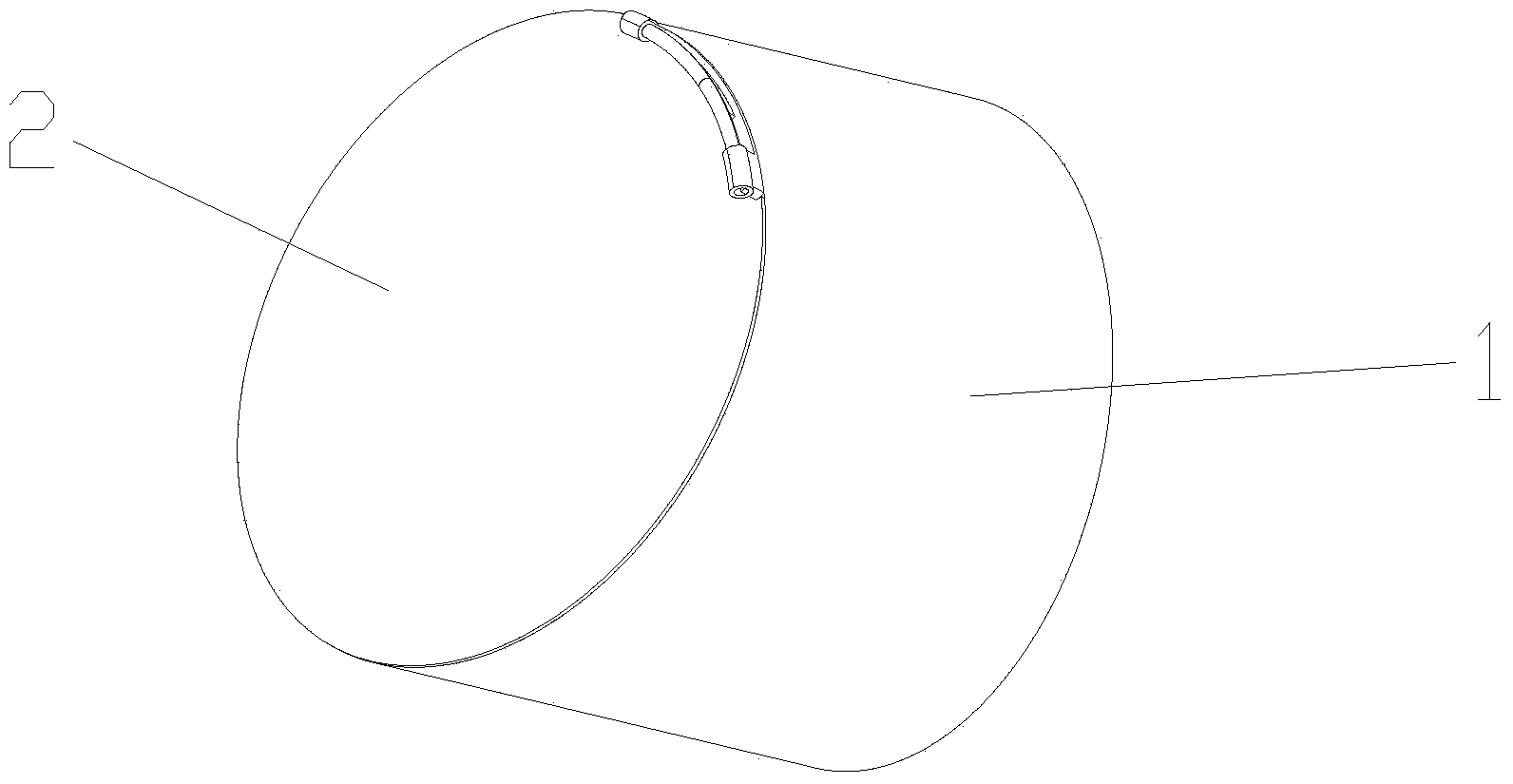

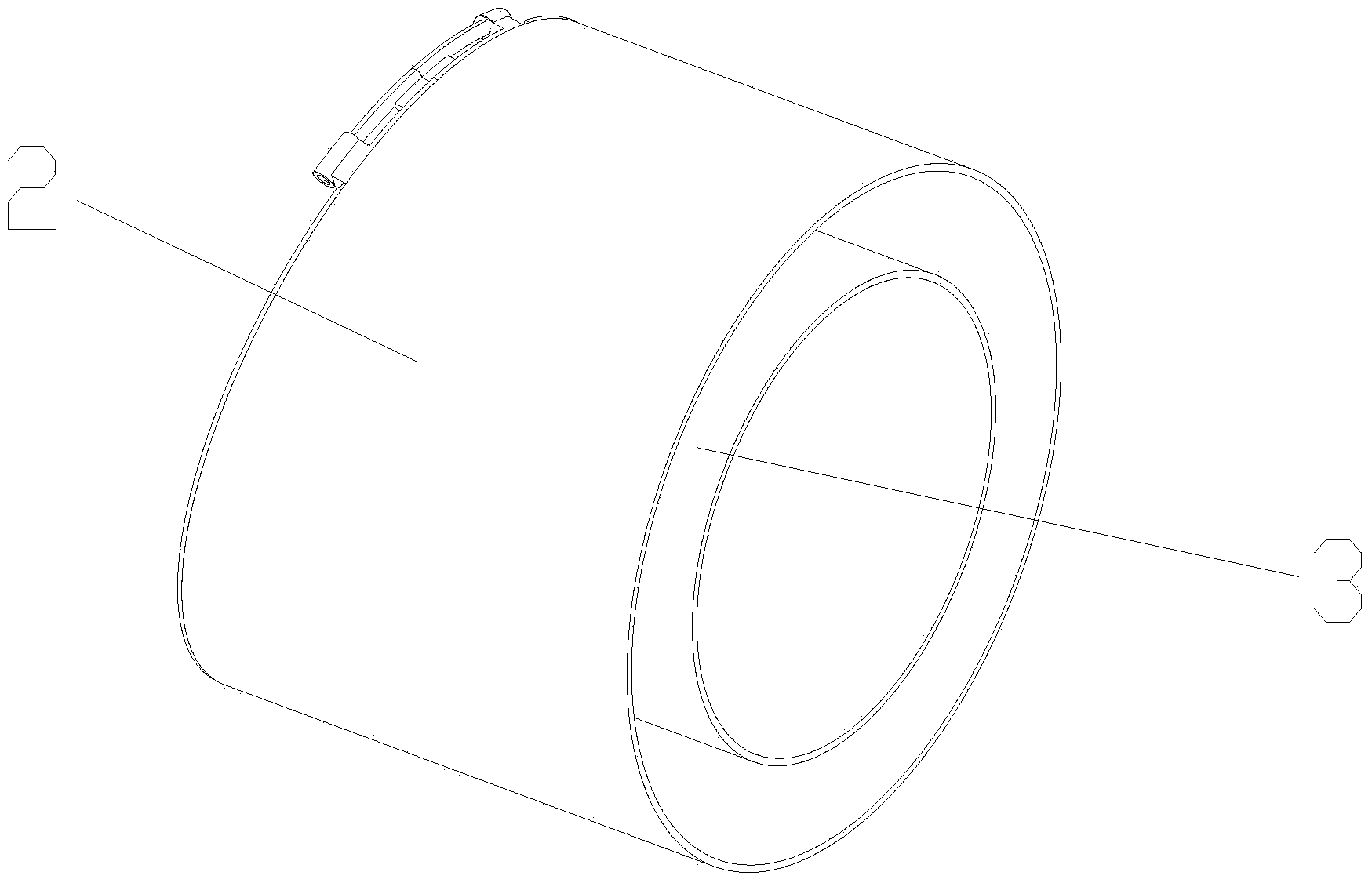

[0014] as attached figure 1 , 2 The shown down filling tube of the present invention includes a tube body 1, a baffle 2 and a torsion spring (not shown in the figure); the tail end of the tube body 1 is provided with a baffle 2; the baffle The piece 2 is hinged with the tube body 1; the hinge of the tube body 1 and the blocking piece 2 is provided with a torsion spring; the tube body 1 is also provided with an inner sleeve 3.

[0015] In the down-filling tube of the present invention, during the down-feeding process, the airflow conveying down overcomes the torsion of the torsion spring, pushes away the flap, and conveys the down; when the down-feeding is completed, the flap is closed due to the torsion of the torsion spring. The down filling tube of the present invention can only transport down in one direction, and can well prevent the down from flowing backward.

[0016] For the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com