Special adjusting device for crank balance weight of beam-pumping unit

A technology for adjusting devices and pumping units, which is applied in wellbore/well parts, production fluid, earthwork drilling and production, etc., which can solve problems affecting adjustment work, easy damage, and increased force, so as to save operating costs and use The effect of convenience and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

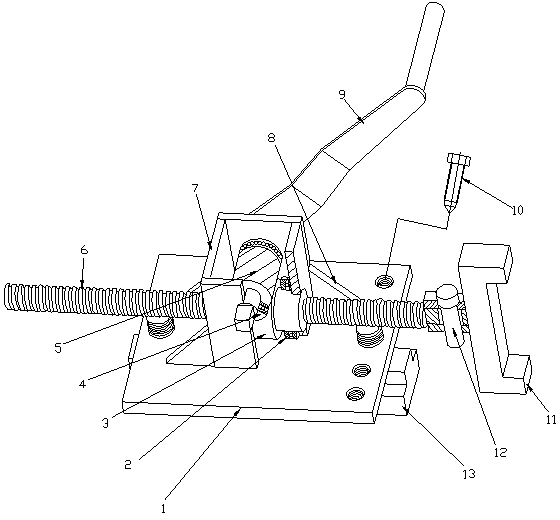

[0021] according to figure 1 As shown, a special adjustment device for the crank balance weight of a beam pumping unit is composed of four parts: a base, a transmission steering mechanism, a lead screw and a crank handle.

[0022] Base 1 is made of rectangular steel plate. A round hole that can pass through the fixing bolt 13 is respectively opened on the center line of the two narrow sides of the base 1, and two (total 4) positioning screw holes are respectively drilled on both sides of one of the round holes. The fixing bolt 13 is a common threaded bolt, with a nut on one end and an inverted T-shaped block connected by riveting and welding at the other end. The inverted T-shaped block can be packed into the T-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com