Centrifugal pump

A centrifugal pump and vane technology, applied in the field of centrifugal pumps, can solve the problems of short service life of impellers, high manufacturing and maintenance costs, and achieve the effects of saving overall cost, improving service life and diversifying fixing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

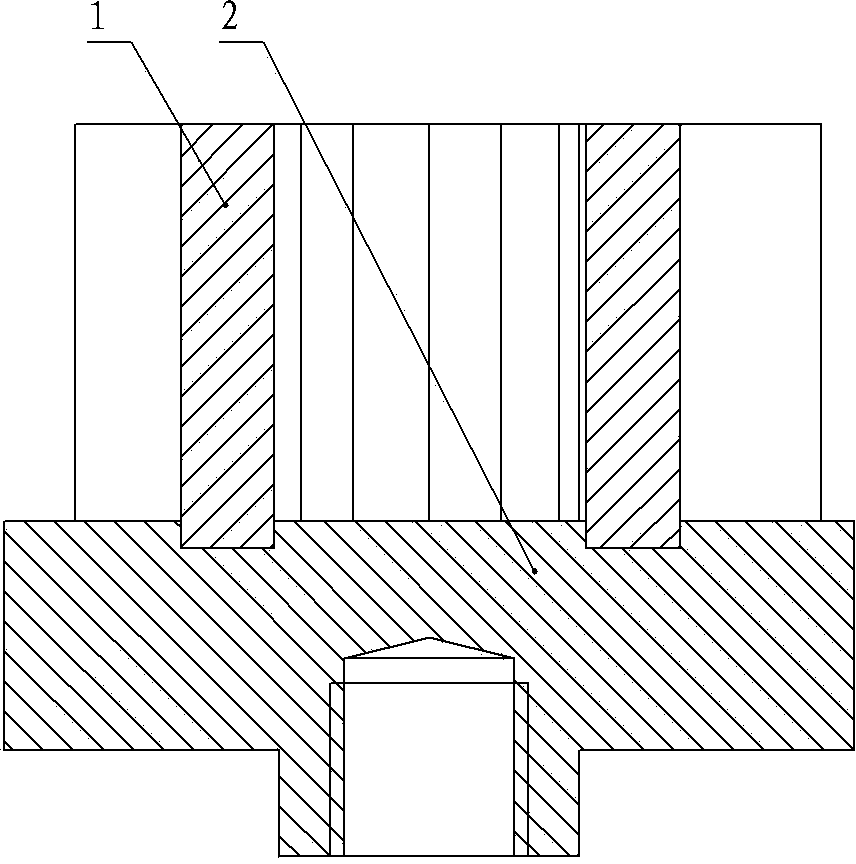

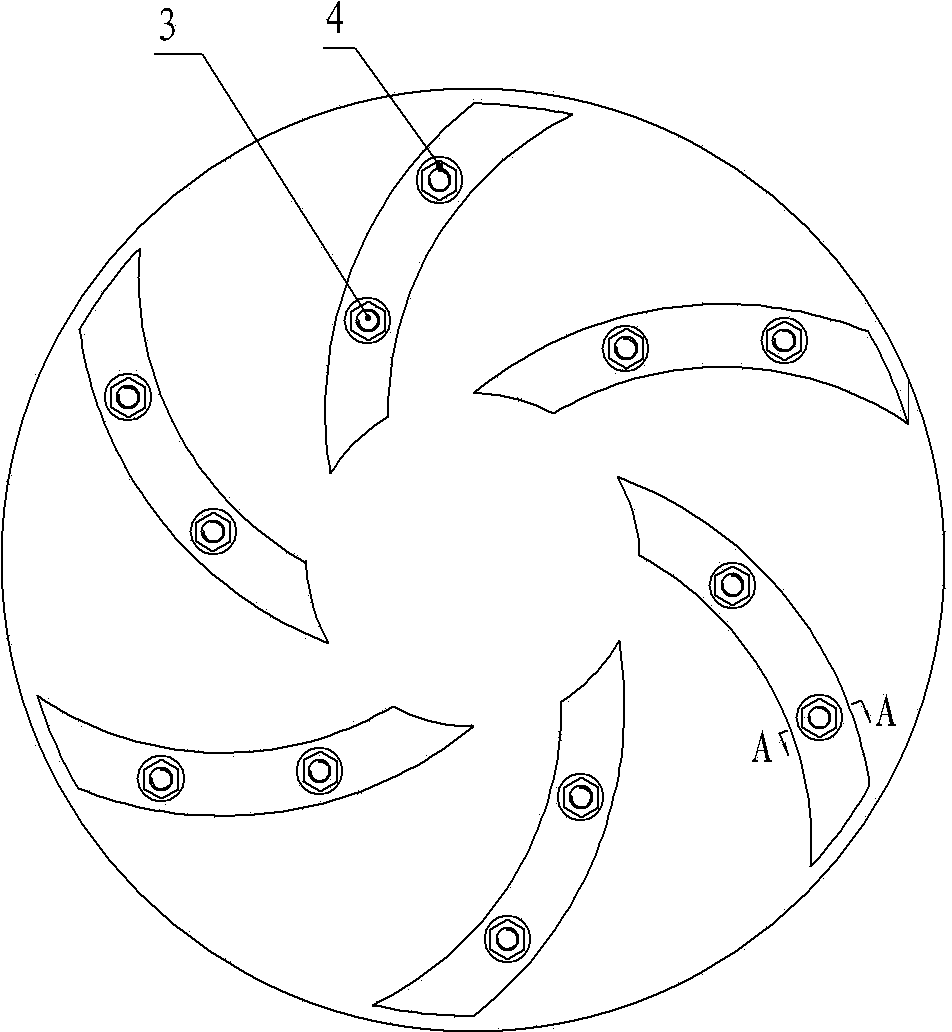

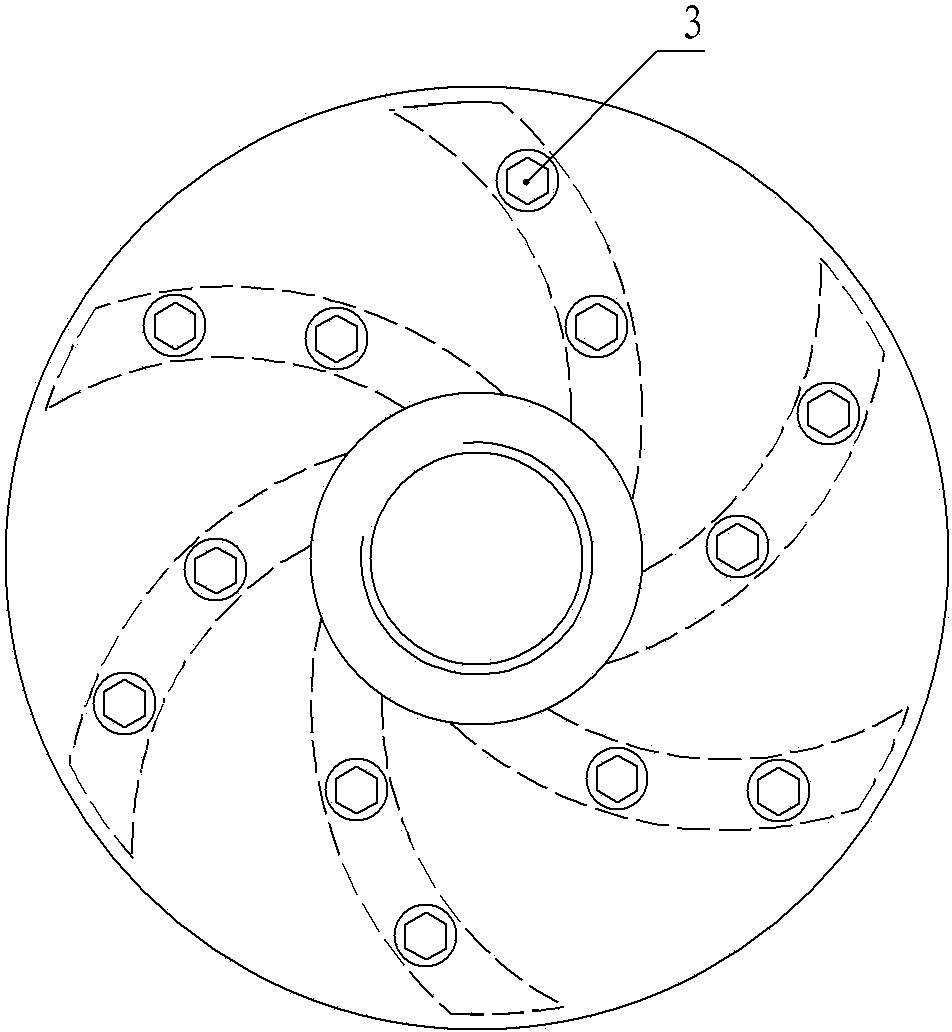

[0029] Embodiment one: if Figure 1~3 The centrifugal pump shown in the figure includes an impeller, which is composed of a blade 1 and a rear cover 2; an installation groove for installing the blade 1 is provided on the end face of the rear cover 2 connected to the blade 1; the bottom of the installation groove is provided with Several through holes, the blade 1 is provided with the connection through hole corresponding to the through hole of the installation groove; There is a countersunk screw hole coaxial with the connection hole of the blade 1; the rear cover 2 is fastened to the blade 1 by bolts 3 and nuts 4 to form an impeller, such as Figure 4 shown.

[0030] The rear cover 2 is made of a wear-resistant material with a hardness greater than or equal to HRC50, and the wear-resistant material is a ceramic material;

[0031] The blade 1 is made of a wear-resistant material with a hardness greater than or equal to HRC50, and the wear-resistant material is a ceramic mate...

Embodiment 2

[0032] Embodiment two: if Figure 1~4 The shown centrifugal pump includes an impeller, the impeller is composed of a blade 1 and a rear cover 2, the structure of the impeller is the same as that of the first embodiment; the rear cover 2 is made of a wear-resistant material with a hardness greater than or equal to HRC50, and the wear-resistant material is a ceramic material ; The surface of the blade 1 is inlaid with a wear-resistant material with a hardness greater than or equal to HRC50, and the wear-resistant material is a ceramic material.

Embodiment 3

[0033] Embodiment three: as Figure 1~4 The shown centrifugal pump includes an impeller, the impeller is composed of a blade 1 and a rear cover 2, the structure of the impeller is the same as that of the first embodiment; the rear cover 2 is made of a wear-resistant material with a hardness greater than or equal to HRC50, and the wear-resistant material is a ceramic material ; The surface of the blade 1 is inlaid with a wear-resistant material with a hardness greater than or equal to HRC50, and the wear-resistant material is hard alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com