Self-sensing magnetorheological damper adopting spiral damping channel

A magnetorheological damper and damping channel technology, applied in the field of vibration buffering, can solve problems such as power consumption, and achieve the effects of reducing power consumption, extending effective length, and improving magnetic field utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

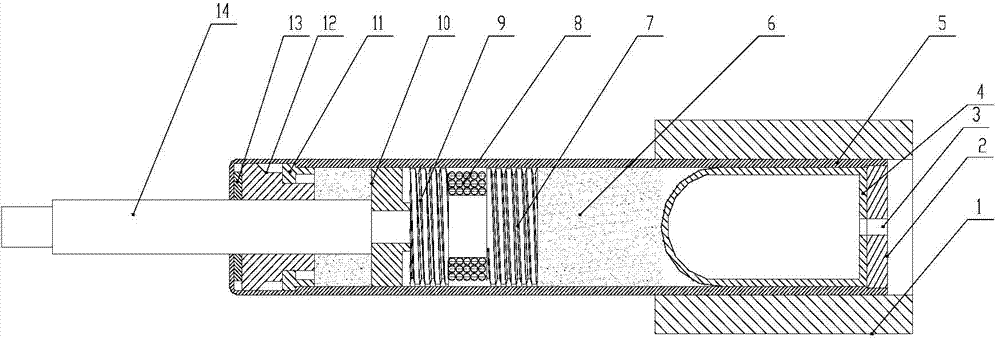

[0020] Please refer to figure 1 , is a structural schematic diagram of an embodiment of the magnetorheological damper provided by the present invention, which includes: a working cylinder, a piston, a piston rod 14 and an energy storage capsule 4 .

[0021] Among them, the piston is mainly composed of piston head I7, excitation coil 8, piston head II9 and guide 10, the working cylinder is composed of outer cylinder 5 and bottom cover 2, and the outer cylinder 5 and bottom cover 2 are fixed by threads; the piston is arranged in the working cylinder , The working cylinder is divided into chamber Ⅰ and chamber Ⅱ, one end of the piston rod 14 is fixed on the piston, and the other end passes through the chamber Ⅱ and extends out of the working cylinder.

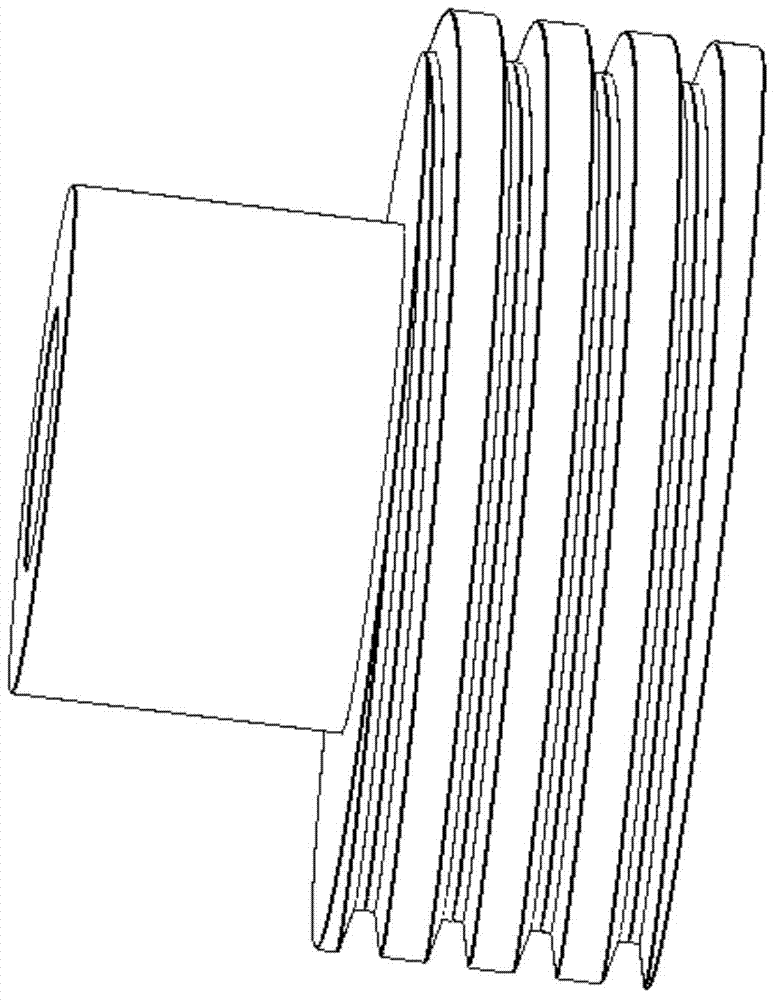

[0022] In this embodiment, the piston is provided with an exciting coil 8 and a helical damping channel. Specifically, the piston head I7 and the piston head II9 form an I-shaped groove for winding the excitation coil 8, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com