Ball valve

A technology for ball valves and valve bodies, which is applied in the direction of valve devices, cocks including cut-off devices, engine components, etc., which can solve the problems of reduced sealing effect and achieve the effect of ensuring sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

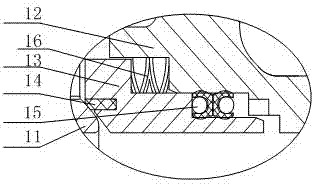

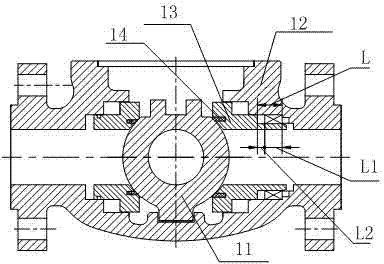

[0027] This embodiment provides a specific structure of the ball valve disclosed in the present invention, such as Figure 5 As shown, it includes a retainer 53 between the valve ball 51 and the valve body 52, a first seal 54 and a second seal 55 are provided between the retainer 53 and the valve body 52, and the first seal 54 is close to the retainer 53, the second seal 55 is set close to the valve body 52, and the valve body 52 and the holder 53 are respectively provided with valves for preventing the first seal 54 from moving to the valve body 52 and the second seal 55 from moving to the holder 53. Barrier 56 .

[0028]The technical solution above is the core technical solution of the present invention. When the left side of the ball valve is pressurized for the first time, the first sealing member 54 moves to the right under the pressure and is blocked by the blocking part 56 on the valve body and does not move again. , and realize the sealing between the retainer 53 and ...

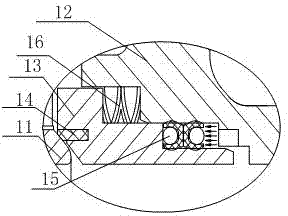

Embodiment 2

[0034] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is:

[0035] In this embodiment, the positions of the first shoulder 561 and the second shoulder 562 are facing each other, and the contact surface between the first stopper 57 and the second stopper 58 is a plane to ensure the contact between the first stopper and the second stopper. Face to face contact is sufficient. This structure can reduce the processing cost of the first stopper 57 and the second stopper 58 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com