Bushing sleeve for vehicle frame and forming method thereof

A technology of bushing and frame, which is applied in the field of bushing and casing for frame and its forming, which can solve the problems of high cost, wall thickness, diameter, and material yield strength that cannot be combined at will, so as to reduce production cost and metal processing The effect of sequence and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

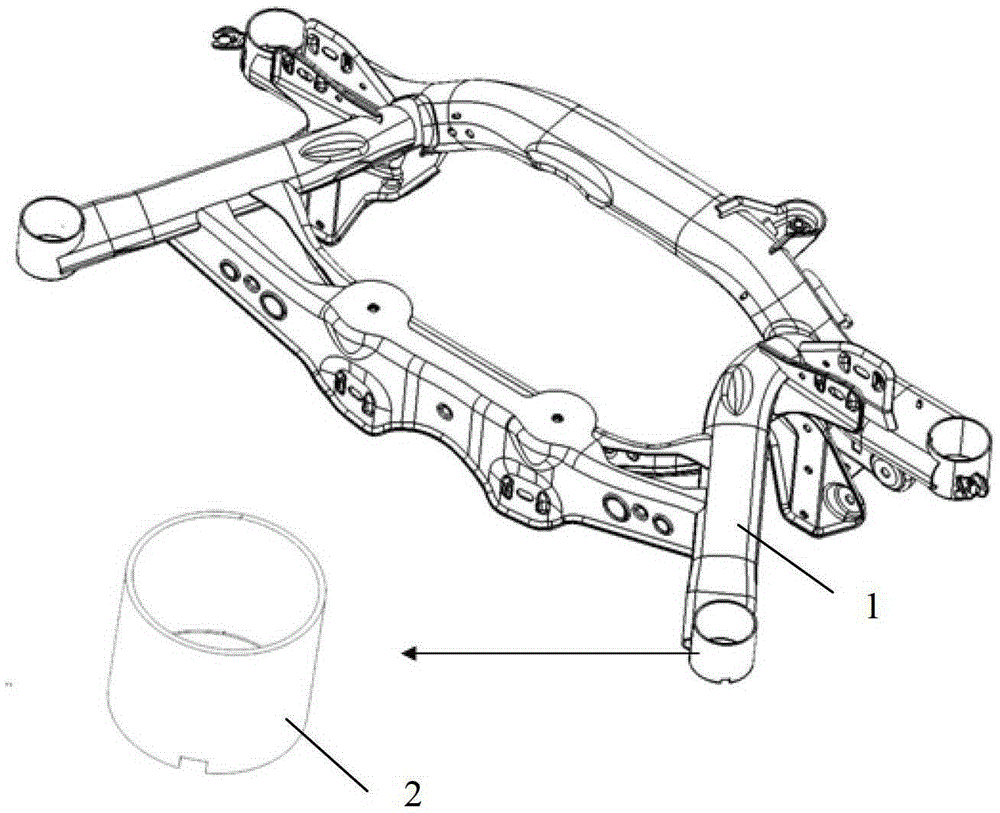

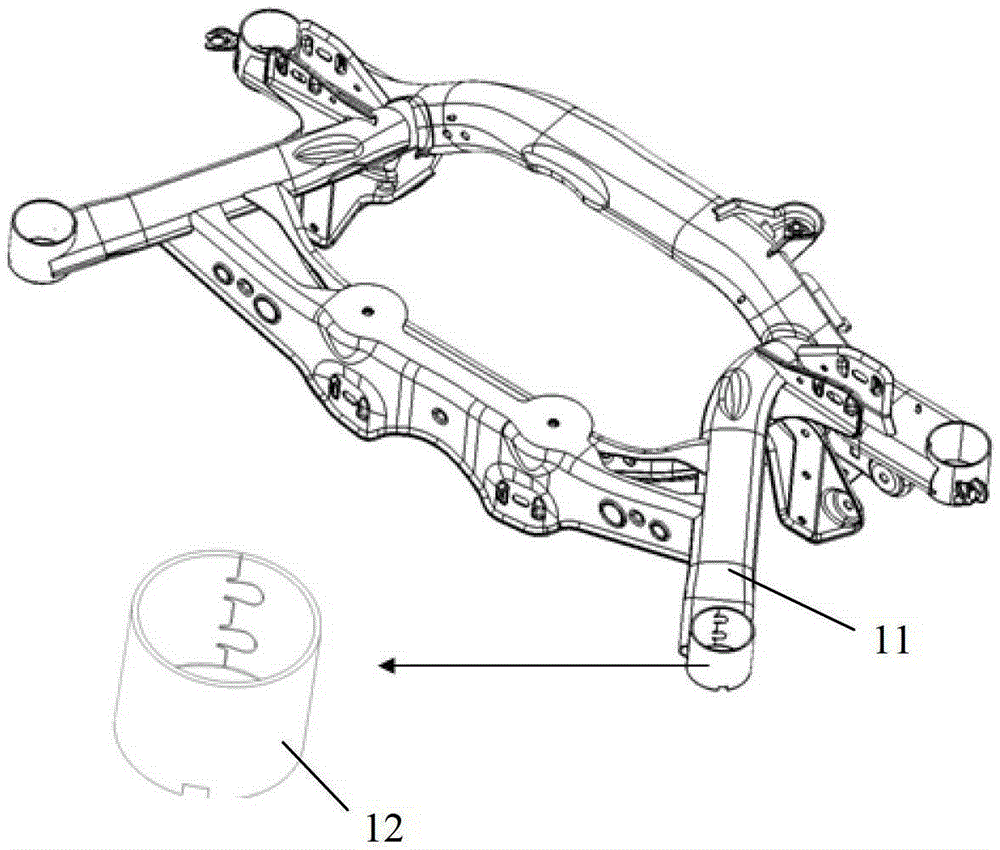

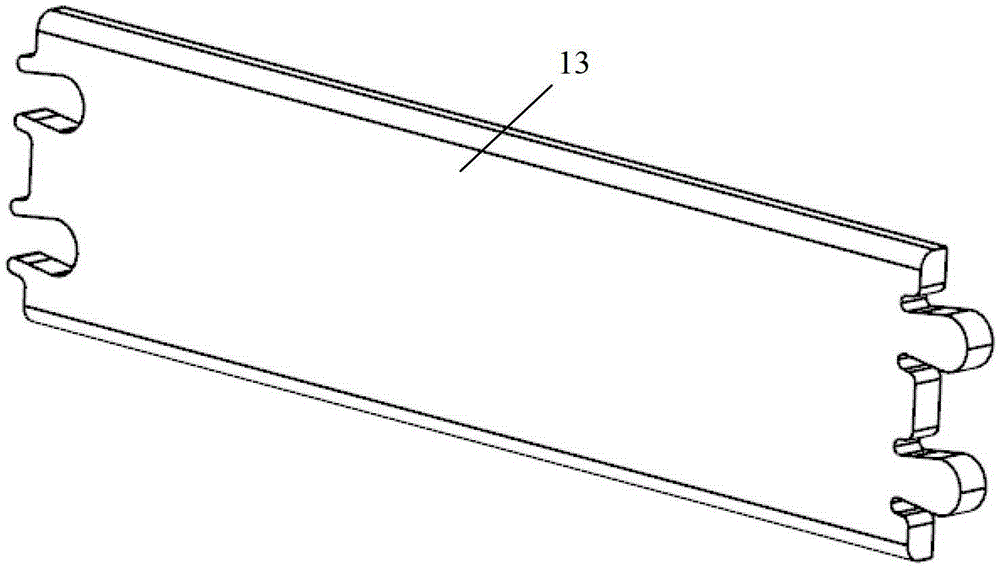

[0028] like figure 2 and Figure 10 As shown, in an embodiment of the present invention, the bushing sleeve 12 for the vehicle frame 11 is a stamped and formed part, which has a seam, and the seam is formed by connecting the convex end and the concave end of the sleeve. The convex part end has a plurality of convex parts 131, and the concave part end has a plurality of concave parts 132, and a plurality of convex parts 131 and a plurality of concave parts 132 are connected in one-to-one correspondence, and the shapes of the convex parts 131 and corresponding concave parts 132 are similar, and the convex parts 131 and the corresponding concave parts 132 are similar in shape. The corresponding recess 132 is an interference fit to connect the male and female ends of the bushing sleeve together such that the bushing sleeve is in a closed cylindrical shape. The contours of the protrusions 131 and 132 are arc-shaped without acute angles, and the widths of the bases of the protrusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com