Photoelectric composite cable

A photoelectric composite cable and cable core technology, which is applied in the direction of communication cables, cables, circuits, etc., can solve the problems of difficult installation and single function, and achieve the effects of increasing installation speed, reducing friction, and avoiding repeated wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment the present invention is described in further detail, but structure of the present invention is not limited to following embodiment:

[0015] 【Example】

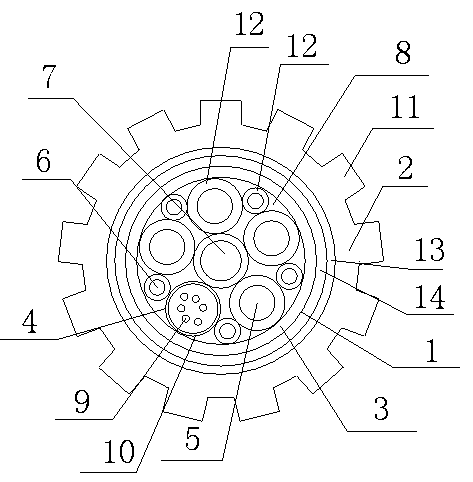

[0016] like figure 1 As shown, the photoelectric composite cable includes a cable core 1 and an outer sheath 2 wrapping the cable core 1. The cable core 1 includes a wrapping layer 3, and the wrapping layer 3 is provided with an optical fiber unit 4 and a signal line copper conductor. 5. The power supply copper conductor 6 and the central strengthening member 7, the central strengthening member 7 is located at the center of the wrapping layer 3, the optical fiber unit 4, the signal line copper conductor 5, and the power supply copper conductor 6 are arranged around the central strengthening member 7, and the optical fiber unit 4 , the signal line copper conductor 5, the power supply copper conductor 6 and the central strength member 7 are all fixed in the wrapping layer 3 by ointme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com