Chip capacitor provided with internal interconnection structure and manufacturing method thereof

A kind of internal interconnection and chip technology, which is applied in the direction of fixed capacitor parts, fixed capacitor dielectric, fixed capacitor lead-out, etc., can solve the problems of limited assembly space and capacitance dependence, so as to ensure the overall size and pole spacing small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

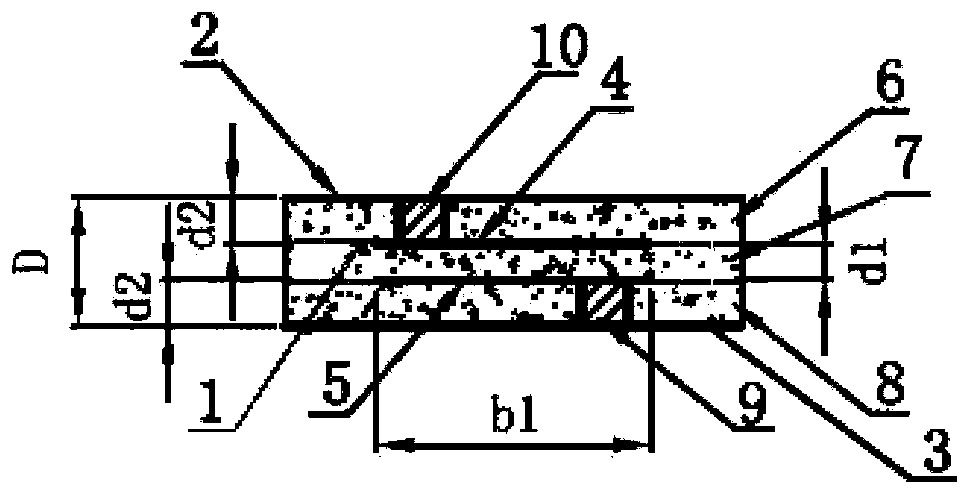

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The following descriptions are only preferred embodiments of the present invention, and it should be pointed out that for those of ordinary skill in the art, without departing from the principle of the present invention, some design and structure improvements and preparation method modifications can also be made. And retouching should also be regarded as the protection scope of the present invention.

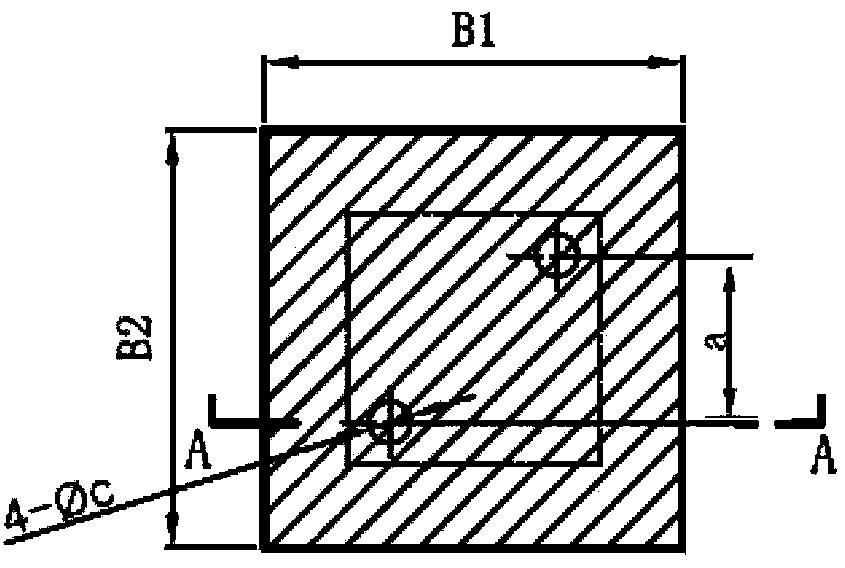

[0021] The chip capacitor with an internal interconnection structure of the present invention includes a multilayer body, an internal electrode, and an external electrode; the multilayer body is obtained by sintering a multilayer dielectric layer; the multilayer body contains two oppositely established internal electrodes; The upper and lower surfaces of the multilayer body are provided with external electrodes, and the external electrodes are elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com