Chlorine dioxide composite disinfectant generator employing electrolytic process

A technology of chlorine dioxide and disinfectant, which is applied in the direction of electrolysis components, electrolysis process, cells, etc., can solve the problem of salt consumption, electricity consumption, ClO2 production efficiency is not ideal, the corrosion resistance of quartz diaphragm is not ideal, conductivity, micro The hole diameter is not ideal, etc., to achieve the effect of good cooling effect, low failure and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

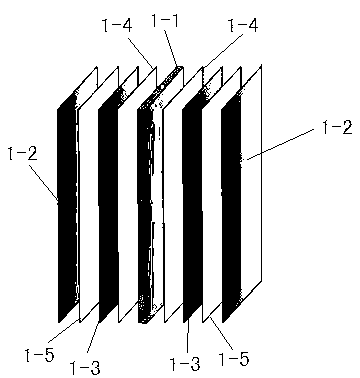

[0017] Refer to attached figure 1 :

[0018] The electrolytic cell of this embodiment is a double-sided bipolar structure, in the middle of which is a mesh active anode 1-1 with multiple coatings such as ruthenium, iridium, and palladium, and on both sides are coated with catalytic materials nickel, cobalt oxide material-coated mesh catalytic cathode 1-2, and the catalytic cathode is an equipotential sandwich structure. An intermediate electrode 1-3 is installed between the active anode 1-1 and the catalytic cathode 1-2, a PTF mesh diaphragm 1-4 is installed between the active anode 1-1 and the intermediate electrode 1-3, and the intermediate electrode 1 A PTFE microporous permeable electrolytic diaphragm 1-5 is installed between -3 and the catalytic cathode 1-2 on both sides.

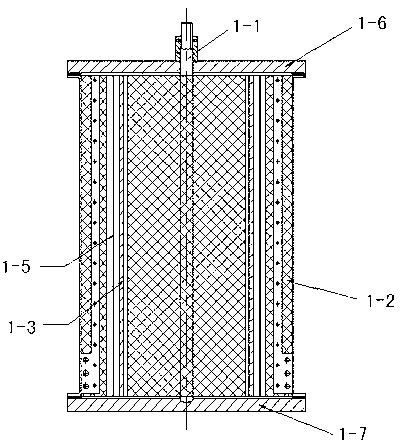

[0019] Refer to attached figure 2 :

[0020] When the electrolytic cell is assembled, its active anode 1-1, catalytic cathode 1-2, intermediate electrode 1-3, and PTFE microporous permeable membra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com