Exotensioned structural members with energy-absorbing effects

A technology for structural components and energy absorption, which is used in the field of manufacturing three-dimensional structural components, joints and fasteners, and three-dimensional structural components, which can solve the problems of neglecting combined loading and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] In the following description, for purposes of illustration and not limitation, specific details are set forth, such as specific embodiments, procedures, techniques, etc., in order to provide a thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced in other embodiments that depart from these specific details.

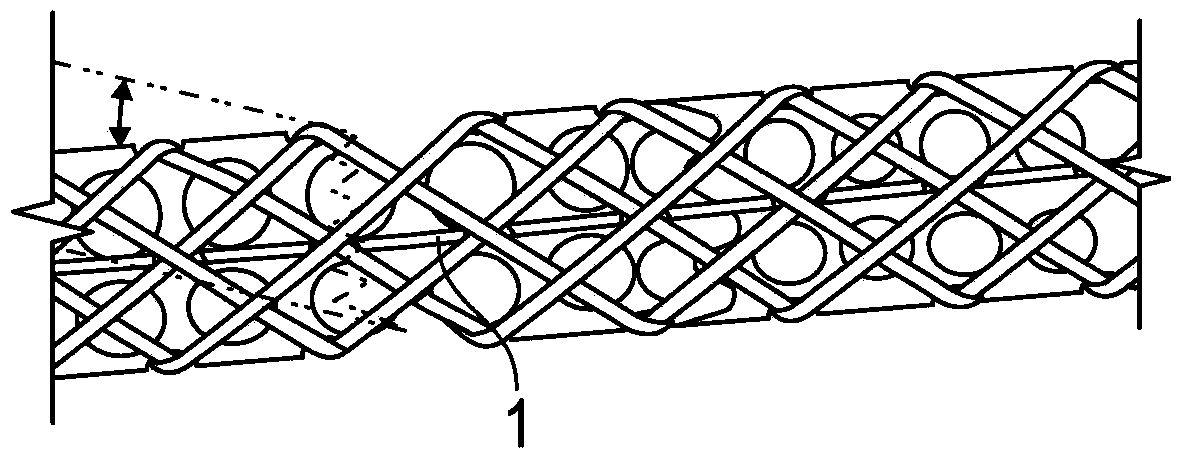

[0081] The technical features described in this application can be used to construct various embodiments of energy absorbing structural members (hereinafter also referred to as "Brockwell structures").

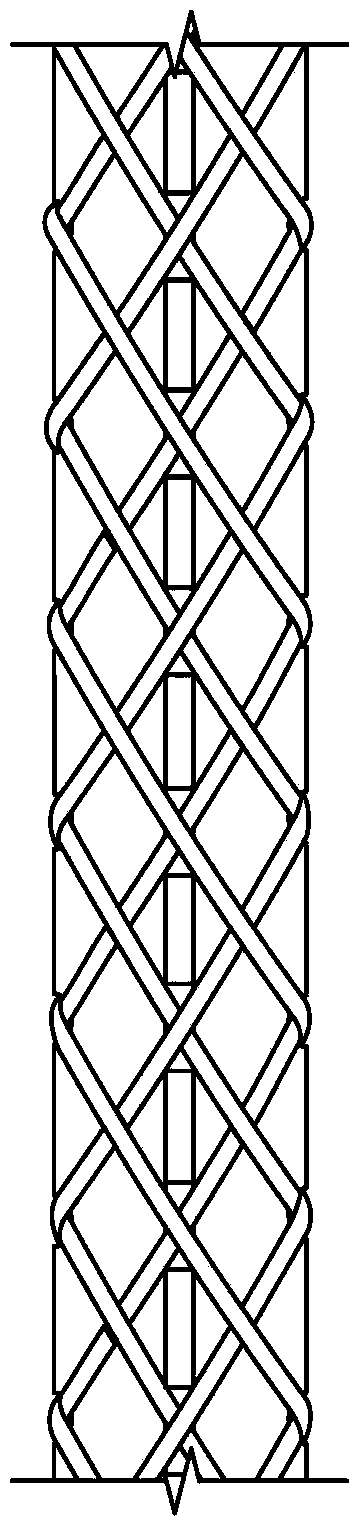

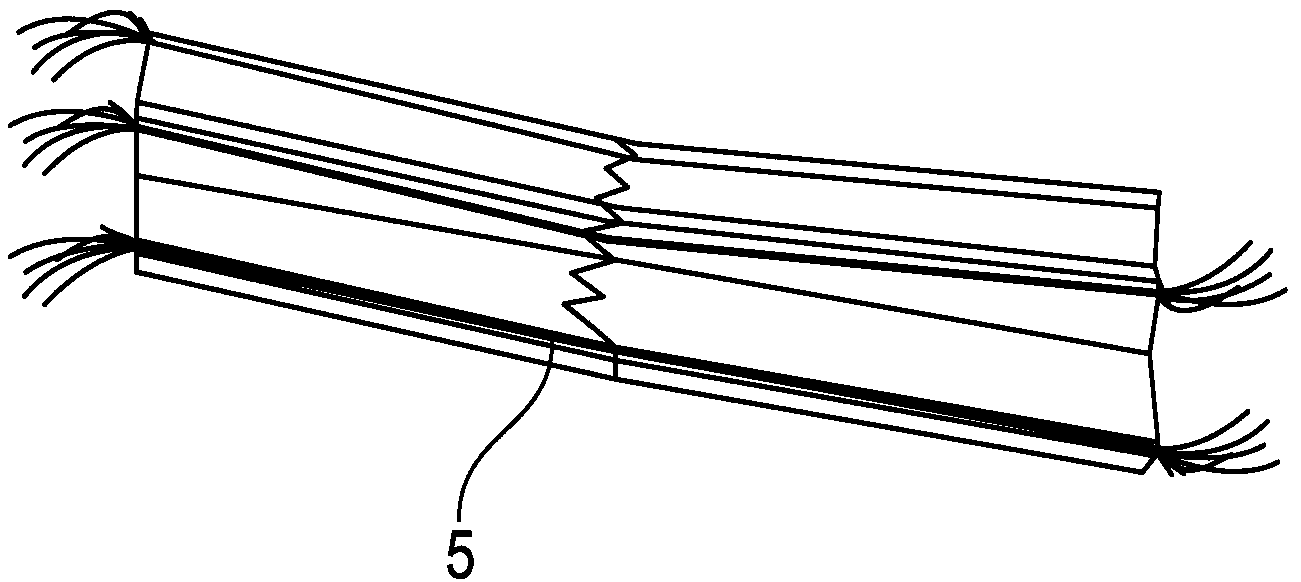

[0082] In one proposal, the energy absorbing structural member with enhanced load capacity per unit mass has a strip of material formed into a skeleton of a desired shape. Spaced notches are provided on the sides of the strip of material. Tensile material is woven into the desired weave around the carcass and placed in the recesses.

[0083] By providing spaced notches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com