Preparation method and application of purified coronary disease particle

A technology of Guanxin Granules and Radix Paeoniae Rubra, applied in the field of preparation of refined Guanxin Granules, which can solve the problems of large dosage for patients, rough process, and impact on clinical application, and achieve the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

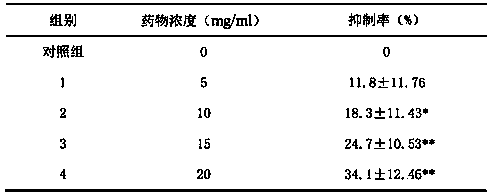

Method used

Image

Examples

Embodiment 1

[0016] Take 456g of Salvia miltiorrhiza, 228g of red peony, 228g of Chuanxiong, 228g of safflower, and 152g of Jiangxiang, and add them to CO 2 In a supercritical extractor, ethanol is used as an entrainer, and the entrainer accounts for 4% by volume of the total extraction solvent. The extraction pressure is 15MPa, the temperature is 30°C, and the CO 2 The flow rate is 1m1 / g crude drug·min, and the extraction time is 150min to obtain supercritical extract, add starch, 70% ethanol to make granules, and dry to make 650g.

Embodiment 2

[0018] Take 456g of Salvia miltiorrhiza, 228g of red peony, 228g of Chuanxiong, 228g of safflower, and 152g of Jiangxiang, and add them to CO 2 In a supercritical extractor, ethanol is used as an entrainer, and the volume percentage of the entrainer in the total extraction solvent is 6%, the extraction pressure is 30MPa, the temperature is 50°C, and the CO 2 The flow rate is 3m1 / g crude drug·min, and the extraction time is 180min to obtain a supercritical extract, which is added with starch and 70% ethanol to make granules, dried and made into 650g.

Embodiment 3

[0020] Take 456g of Salvia miltiorrhiza, 228g of red peony, 228g of Chuanxiong, 228g of safflower, and 152g of Jiangxiang, and add them to CO 2 In the supercritical extractor, ethanol is used as an entrainer, and the entrainer accounts for 5% by volume of the total extraction solvent, the extraction pressure is 20MPa, the temperature is 40°C, and the CO 2 The flow rate is 2m1 / g crude drug min, and the extraction time is 160min to obtain a supercritical extract, add starch, 70% ethanol to make granules, and dry to make 650g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com