Latex balloon sealing device and method for applying same

A sealing device and balloon technology, which can be used in entertainment, toys, toy airplanes, etc., and can solve problems such as labor-intensive, easy to buckle the cord, and easy air leakage of the balloon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 48

[0051] select Figure 37 ~ Figure 84 The structural features of each figure are taken as a kit (1), the thickness of the kit (1) is 0.3mm~1.8mm, the diameter of the clamping hole (11) is 1.5mm~6.5mm; the material is plastic (ABS), and the processing method is injection molding;

[0052] select Figure 26 Structural features As the lead wire (2), the lead wire (2) adopts one of the wires such as silk thread, glue wire, rubber-coated steel wire, etc., with a diameter of 0.25mm~0.6mm. The wire is broken into 60mm~180mm long, folded , tie the two ends together and pass through the card hole (11) on the kit (1) to form a latex balloon sealing device;

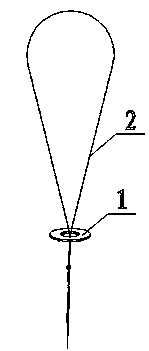

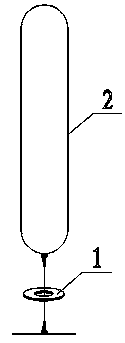

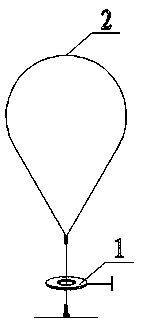

[0053] Depend on Figure 26 as leads (2) respectively and Figure 37 ~ Figure 84 (A total of 48 types) The kit (1) consists of 48 types of latex balloon sealing devices (refer to figure 1 ).

[0054] After the balloon is inflated, wrap the unknotted end of the lead wire (2) around the mouth of the balloon (3), and pull the mout...

Embodiment 49~ Embodiment 96

[0056] select Figure 37 ~ Figure 84 The structural features of each figure are taken as a kit (1), the thickness of the kit (1) is 1.2mm-2.5mm, and the diameter of the clamping hole (11) is 1.5mm-6.5mm; the material is rubber; the processing method is molded or stamped.

[0057] select Figure 27 Structural features As the lead wire (2), the lead wire (2) adopts one of the oblate O-shaped rubber needles, and the oblate O-shaped rubber needle consists of a rubber needle head (21) and a flat O-shaped wire ring. The rubber needle thread (22) is composed of; the diameter of the rubber needle head (21) is 0.6mm-1.2mm, and the length is 7mm-10mm; the diameter of the rubber needle thread (22) is 0.3mm-0.6mm, and the cumulative length is 50mm-200mm; the material is nylon (PA), the processing method is injection molding, and it is processed in groups, with 30 to 100 pieces in each group.

[0058] Use a glue needle gun to drive the glue needle (21) on the lead wire (2) into the hole ...

Embodiment 97~ Embodiment 144

[0062] select Figure 37 ~ Figure 84 Structural features of each picture are taken as a kit (1), the thickness of the kit (1) is 2.0mm~3.2mm, and the diameter of the clamping hole (11) is 1.2mm~6.5mm; the material is wood veneer wood chips or bamboo chips; the processing method is laser Cut to shape.

[0063] select Figure 28 Structural features As the lead wire (2), the lead wire (2) adopts one of the sheet-shaped ring O-shaped rubber needles, and the sheet-shaped ring O-shaped rubber needle consists of 1 rubber needle head (21) and 1 sheet-shaped circular needle. The rubber needle thread (22) of the ring is formed; the diameter of the rubber needle head (21) is 0.6 mm to 1.2 mm, and the length is 7 mm to 11 mm; the diameter of the rubber needle thread (22) is 0.3 mm to 0.6 mm, and the cumulative length is 20 mm to 120 mm;

[0064] The material is polypropylene (PP), the processing method is injection molding, and it is processed in groups, with 40 to 100 pieces in each gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com