Ceramic filter element water purifier without disassembly and washing

A core water purifier and ceramic filter technology, which is applied in the field of non-removable and washable ceramic filter water purifiers, can solve the problems of unbearable ceramic filter cartridges, large tap water swelling force, inconvenient adding filter materials, etc., to extend the interval time, water The effect of increasing the flow rate and reducing the passage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

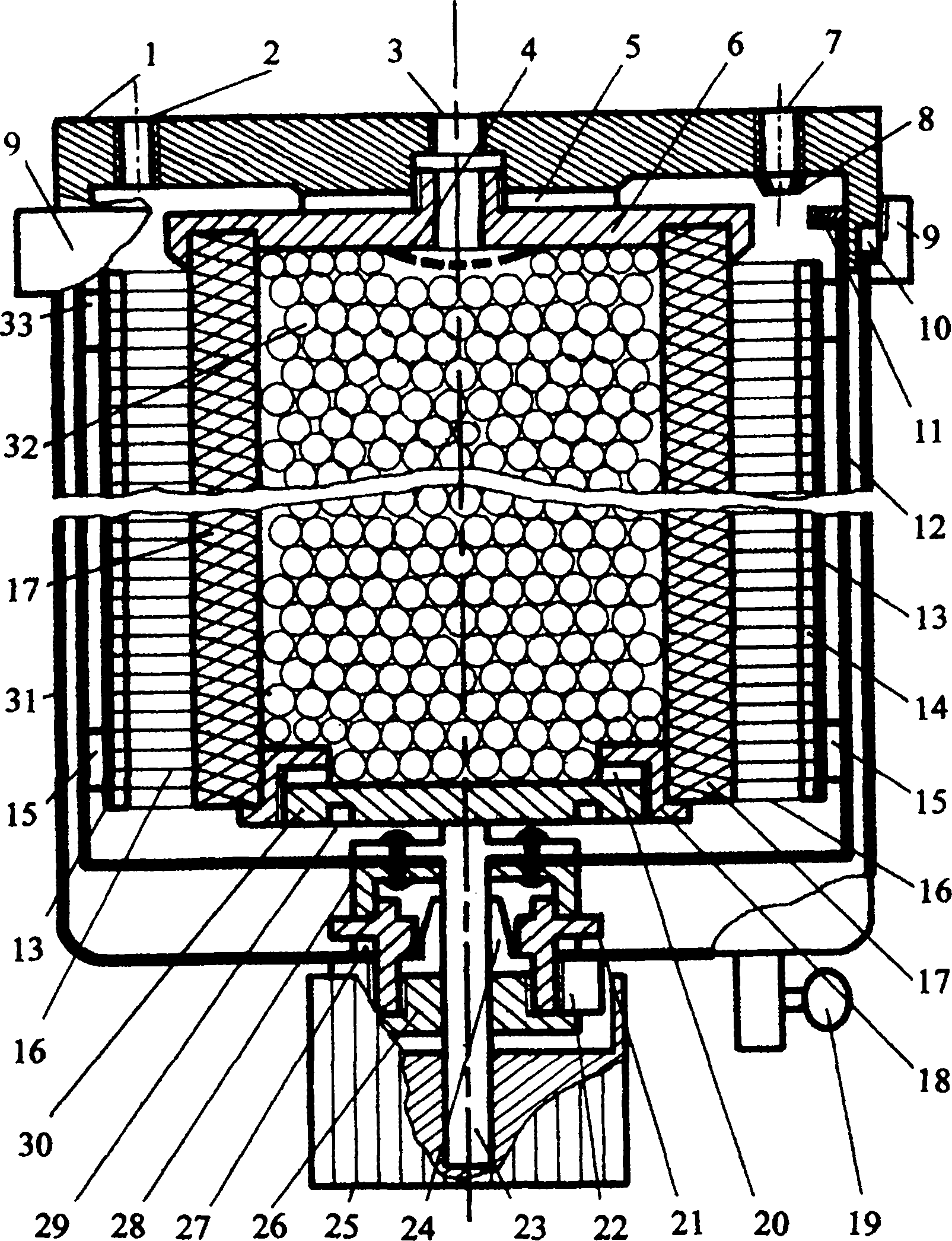

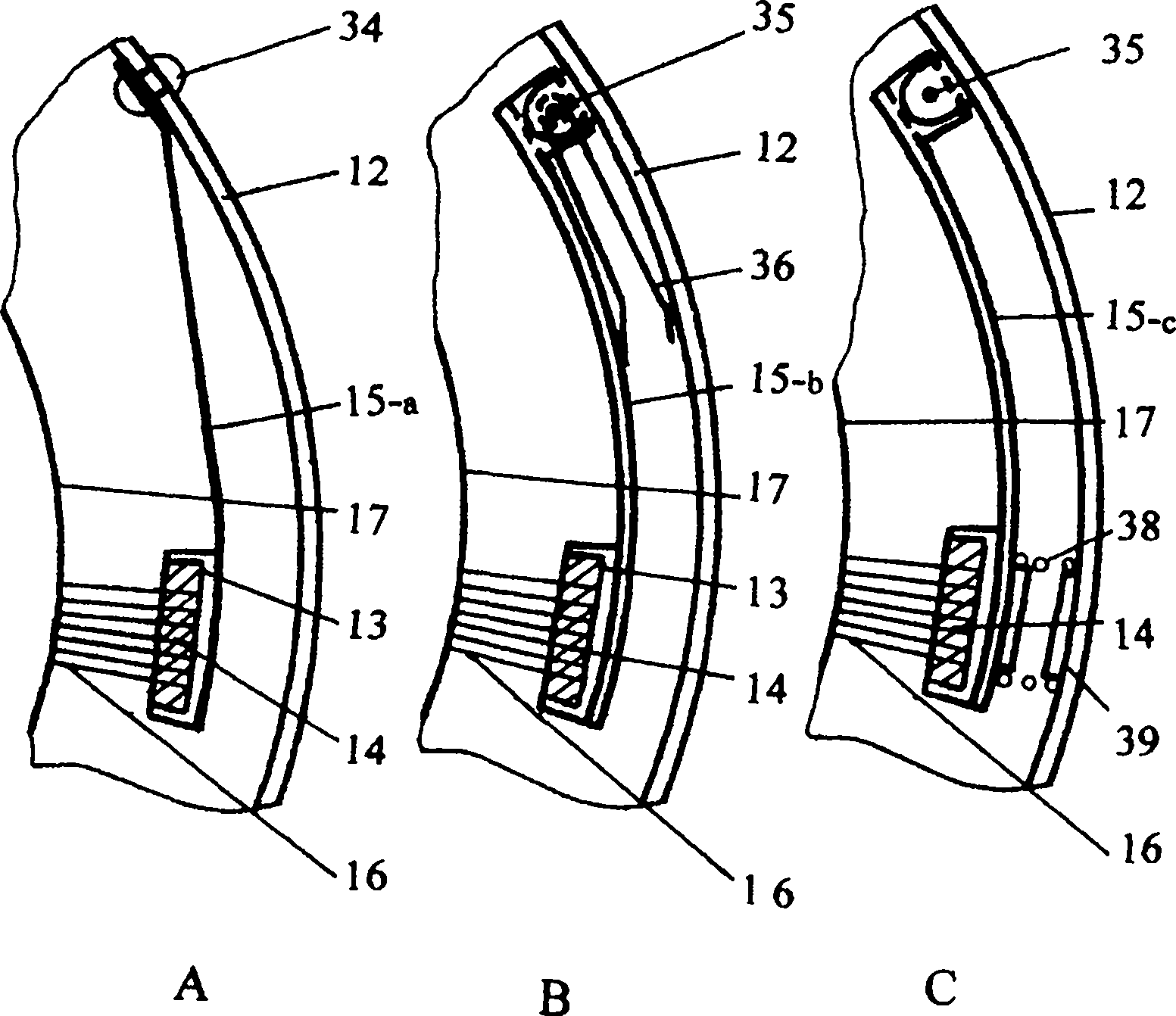

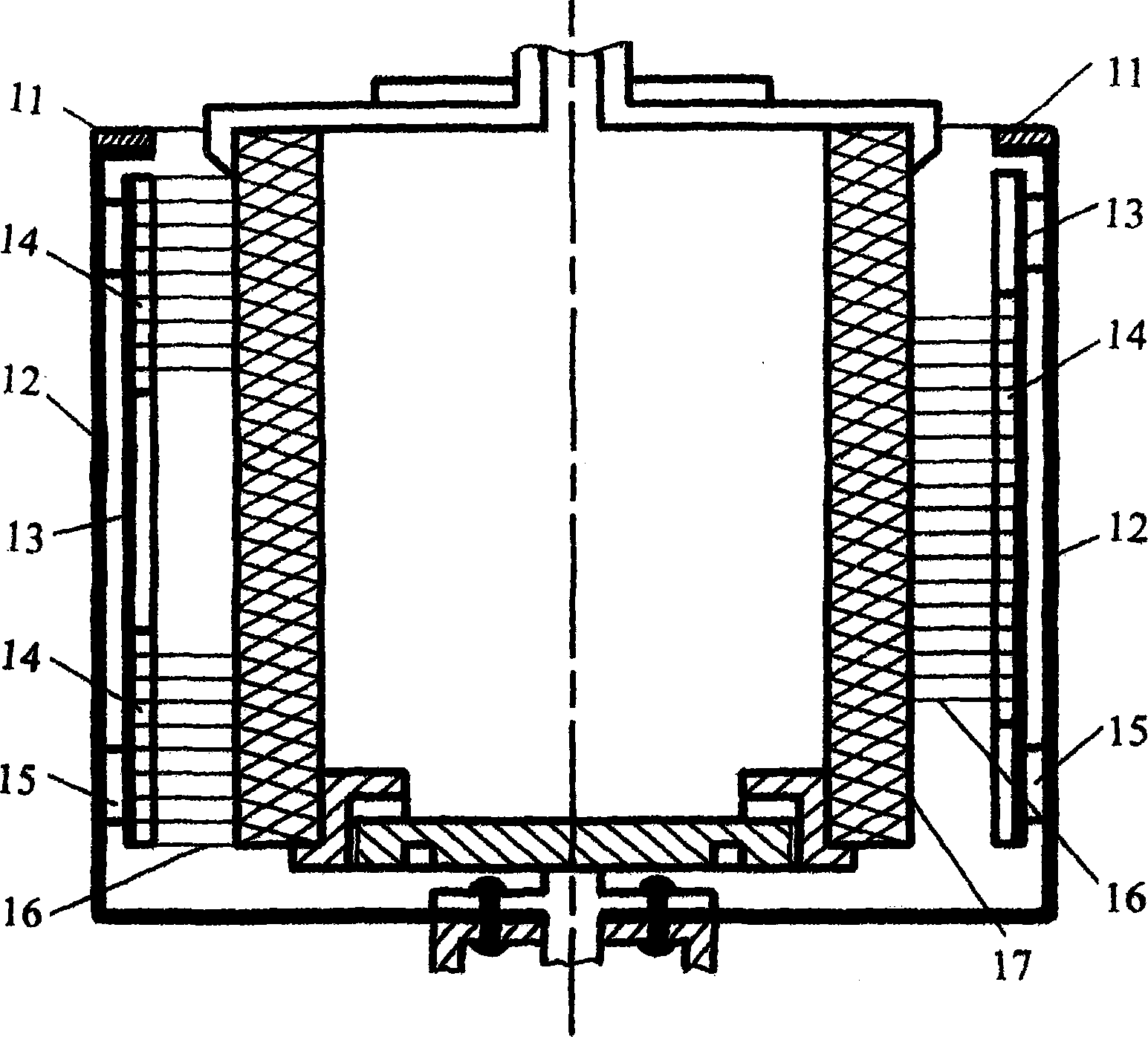

[0024] figure 1 It is a longitudinal schematic diagram of an embodiment in which the scrubbing component is a brush bar structure: it mainly includes: a seat body 1 with a tap water inlet 7 and a tap water and sewage outlet 2 and a purified water outlet 3 to interface with the seat body 1 in a threaded manner The ceramic filter element, a scrubbing assembly is provided between the ceramic filter element and the housing cylinder 31, a spare drain valve 19 is provided at the bottom of the housing cylinder, and the housing cylinder 31 and the seat body 1 are fixed by a fastening ring 9. Each nozzle on the seat body 1 is made with internal threads to match the corresponding external pipe joints. A nozzle 8 with a gradually smaller diameter is provided inside the tap water inlet 7 of the seat body 1.

[0025] The ceramic filter element is made by bonding the upper end of the ceramic filter cartridge 17 and the cap 6 with a short tube of purified water outlet thread in the center. In or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com