Comprehensive treatment method and treatment system for domestic garbage and sludge

A comprehensive treatment and domestic waste technology, applied in the direction of chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of high operating cost, large natural gas consumption, and poor treatment effect of sludge recovery process, and achieve improvement Production efficiency, improvement of utilization rate, and the effect of meeting environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

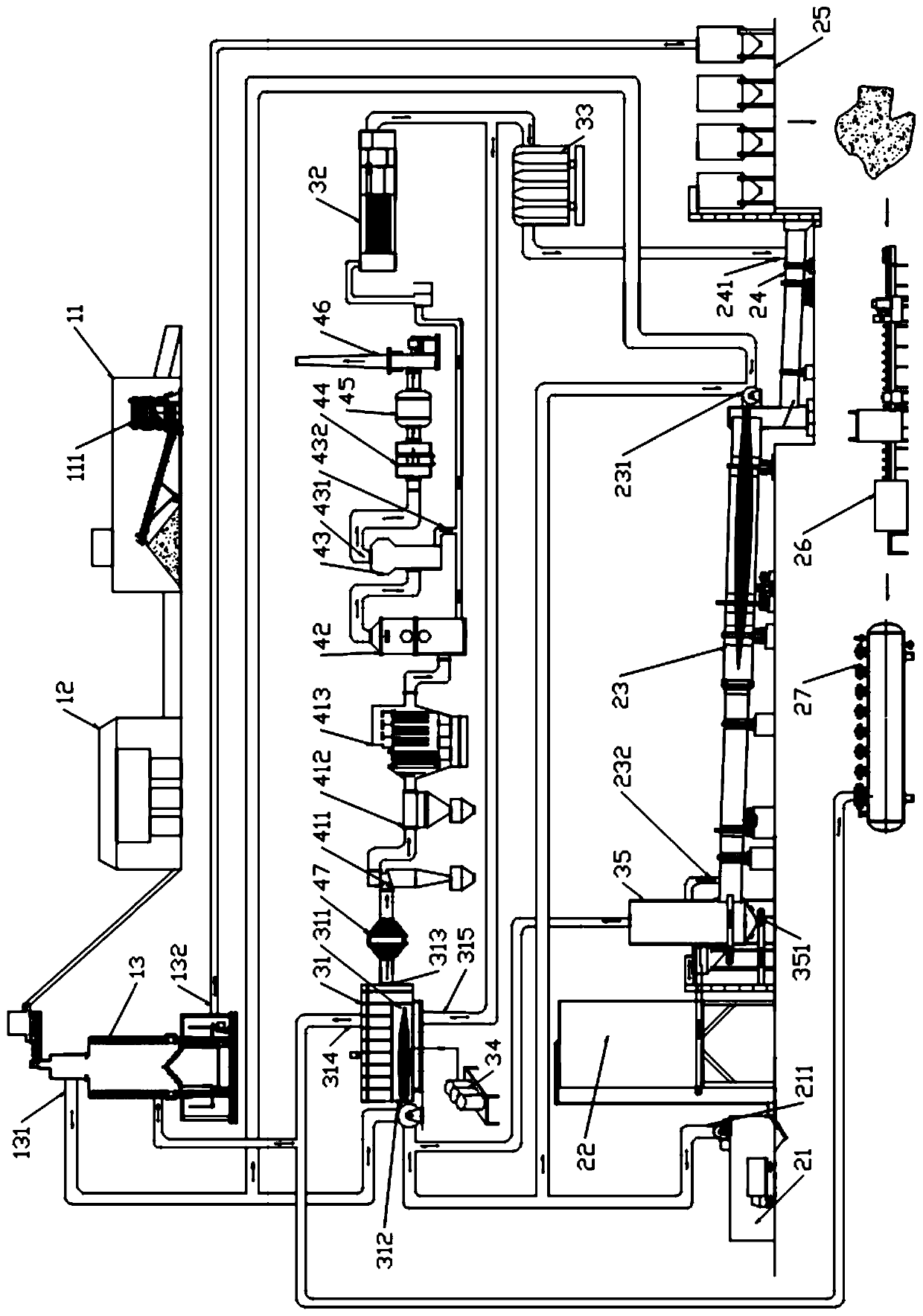

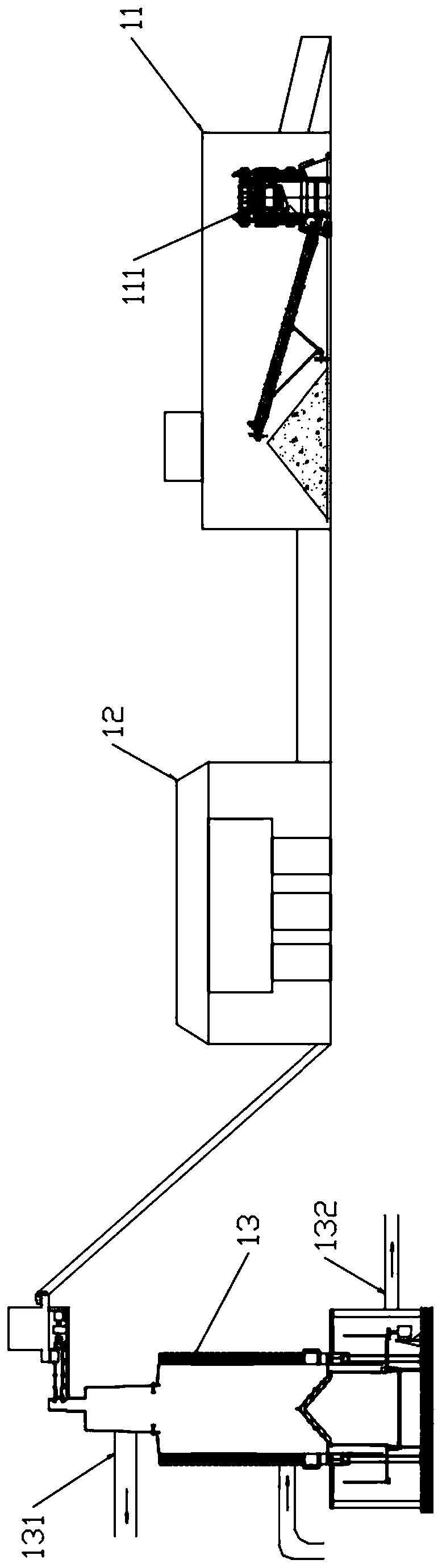

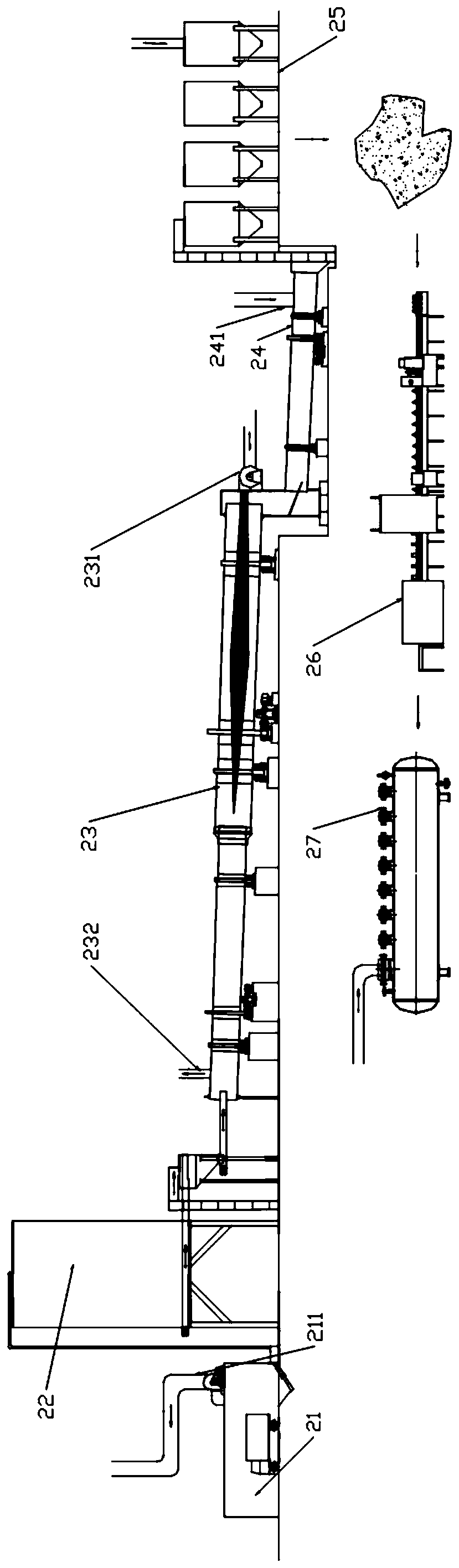

[0071] see Figure 1 to Figure 5 , a comprehensive treatment method for domestic waste and sludge in this embodiment, including the following treatment steps,

[0072] 1) Garbage pyrolysis process:

[0073] Step 1.1: put the garbage into the negative pressure crushing workshop 11, crush it three times through the crusher 111, and obtain garbage particles with a length of less than 3 cm, then sort and remove iron, and then put it into the furnace with a temperature of 1200-1250 °C Carry out pyrolysis in the pyrolysis furnace 13, and produce slag and the combustible gas that is made up of hydrogen, methane and carbon monoxide etc.;

[0074] Step 1.2: Transport the combustible gas to the steam boiler 31 equipped with a combustion chamber 311, and carry out sufficient combustion at a high temperature above 1100°C for more than 3s to generate steam and flue gas; specifically, the steam boiler 31 uses storage Thermally insulated furnace;

[0075] Step 1.3: The flue gas is subject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com