Plasma cutting fume processing system and method for spiral welded steel pipe

A technology of spiral welding and processing system, applied in the field of welding fume purification, can solve the problems of affecting operation, difficult to achieve, smoke and dust, etc., and achieve the effect of solving the asynchronous change, reducing the passing resistance and expanding the dust collection area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

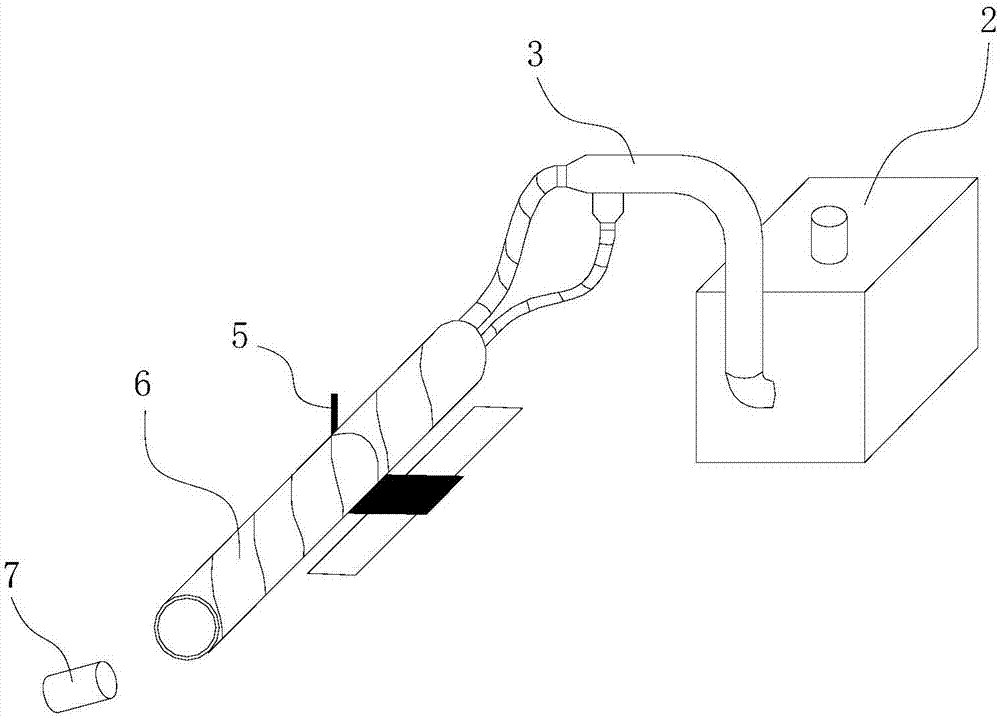

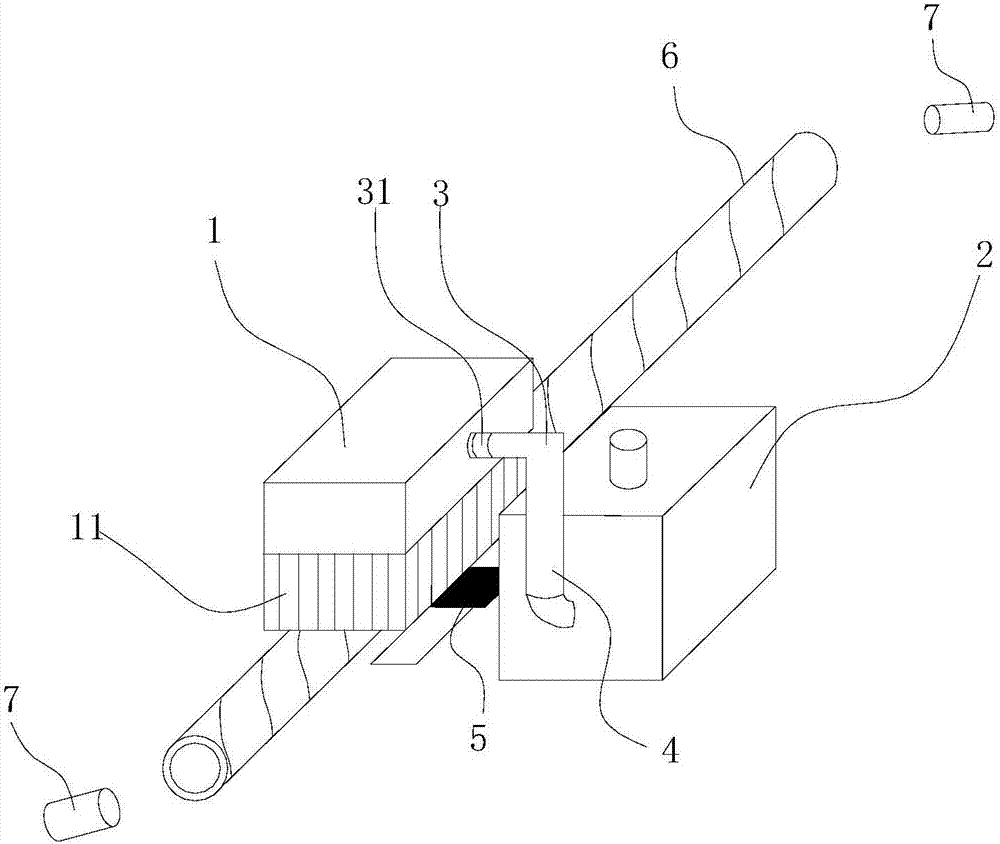

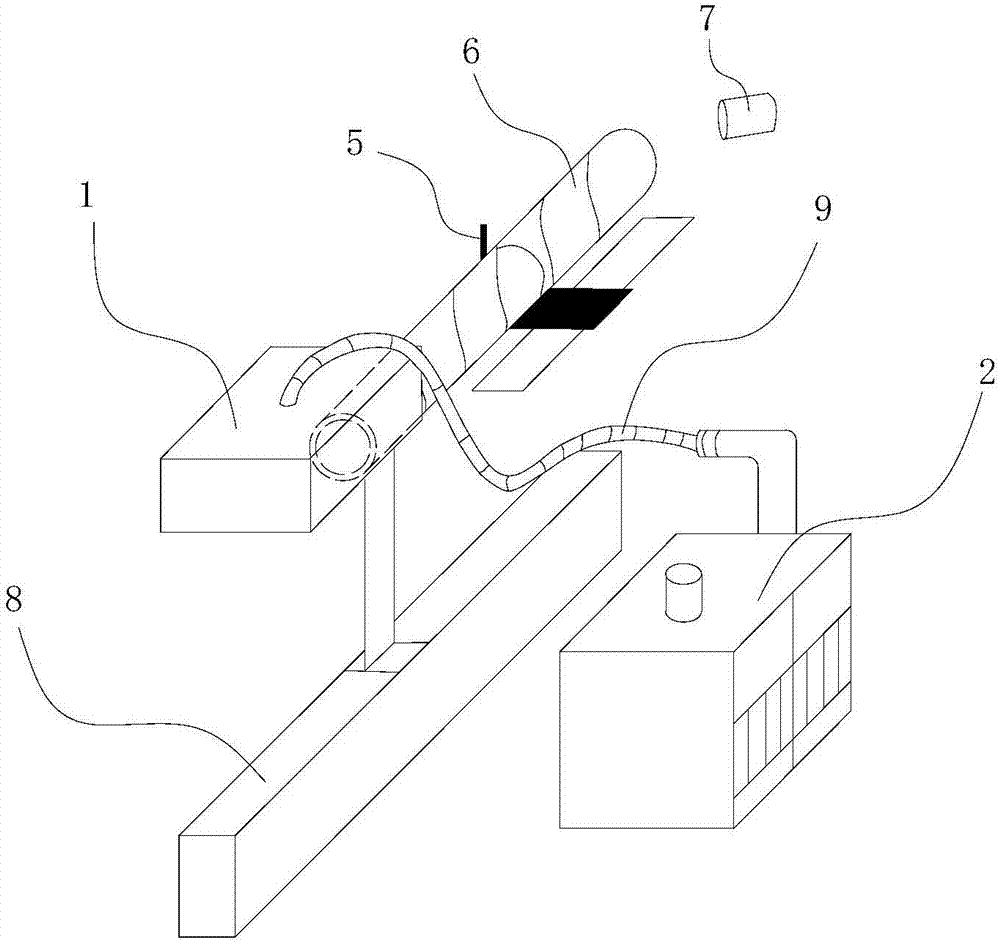

[0029] Such as Figure 4 As shown, the spiral welded steel pipe plasma cutting fume treatment system of the present invention includes: a dust collection cover 1, a dust removal host 2, and a blower 7; the spiral welded steel pipe plasma cutting fume treatment system also includes a rigid dust removal pipe 3;

[0030] The lower surface of the dust collection hood 1 is provided with at least two suction ports; the dust suction ports are evenly distributed along the length direction of the dust collection hood 1; the lower surface of the dust collection hood 1 is surrounded by a soft fireproof curtain 11; The dust removal host 2 has an air outlet 24 and a dust suction main pipe 4;

[0031] The dust suction port of the dust collection hood 1 communicates with the dust suction main pipe 4 through the dust removal pipe 3; the dust suction port corresponds t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com