Superfine particulate matter purifying device

A technology of ultra-fine particles and purification equipment, which is applied in the separation of dispersed particles, chemical instruments and methods, combined devices, etc., can solve the problem that it is difficult to further improve the efficiency of electrostatic precipitators, the efficiency of dust removal is easily affected by dust sources, and the operation of bag filter Large resistance and other problems, to achieve the effect of increasing the condensation effect, compact structure, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

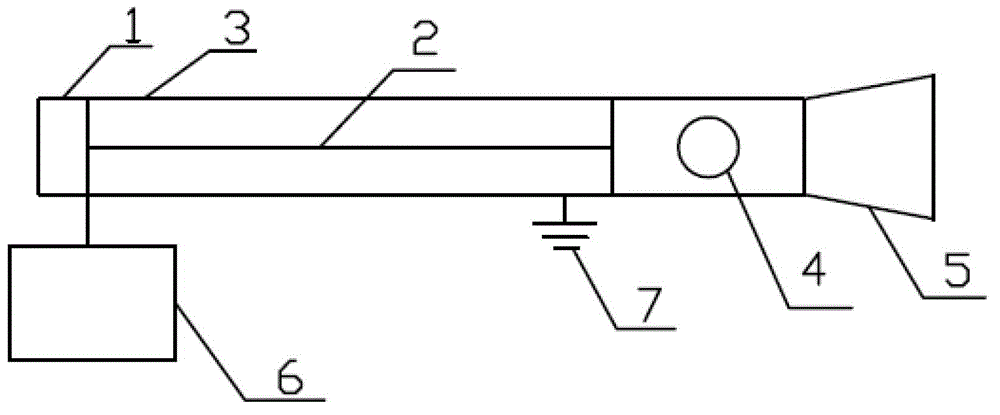

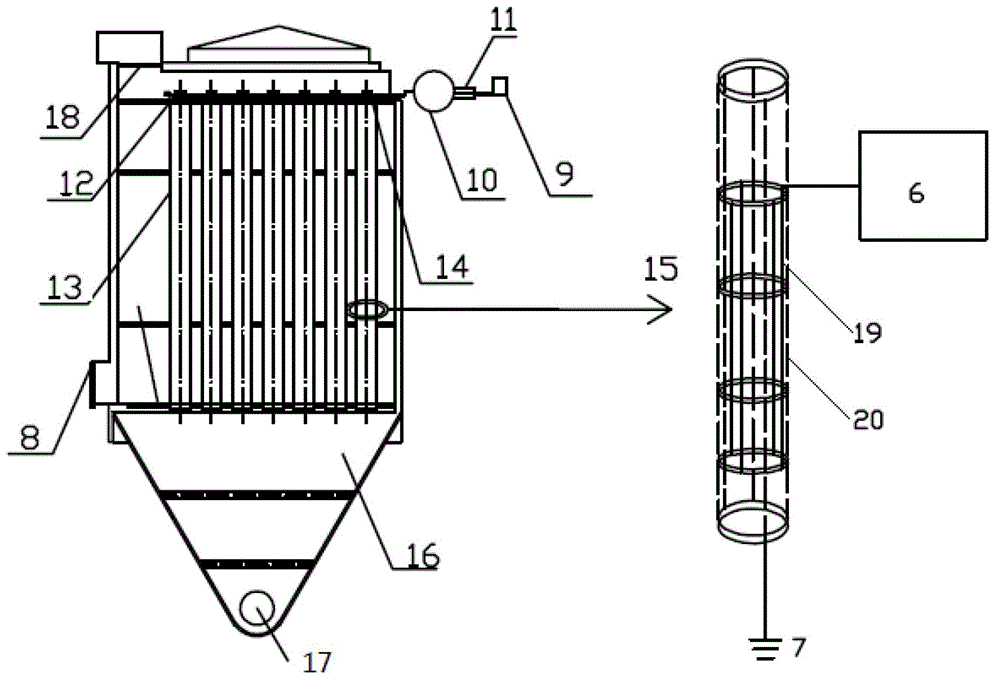

[0027] The present invention is made up of two parts altogether, and the first part is the gas discharge-coagulation device, see attached figure 1 ; The second part is an electrostatically enhanced bag-type dust removal integrated device.

[0028] The mass fraction of dust particle size 0-2.0μm at the inlet of the dust collector is 52.3%, the mass fraction of 2.0-5.0μm is 39.1%, the mass fraction of 5.0-8.0μm is 8.2%, and the mass fraction of 8.0-10.0μm is 0.4%. ; The filter bag is made of glass fiber, and the number of bag filter chambers is 6; the applied voltage is 7-16 kV; the filtering wind speed is 2.0m / min-4.0m / min.

[0029] (1) When the filtering wind speed is 2.5 m / min and the applied voltage is 10.5kV, the dust removal efficiency is 99.2%, and when the applied voltage is 15.8kV, the dust removal efficiency is 99.9%.

[0030] (2) When the filtering wind speed is 4.0 m / min and the applied voltage is 10.5kV, the dust removal efficiency is 99.2%, and when the applied vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com