A compressor silencer

A compressor and noise reduction technology, which is applied in the direction of machines/engines, mechanical equipment, liquid variable displacement machinery, etc., can solve the problems that affect the sound resistance performance and service life, uneven air flow distribution, and damage to resistive noise reduction parts. Achieve the effect of increasing the maximum gas passing capacity, reducing the gas passing resistance and preventing local damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

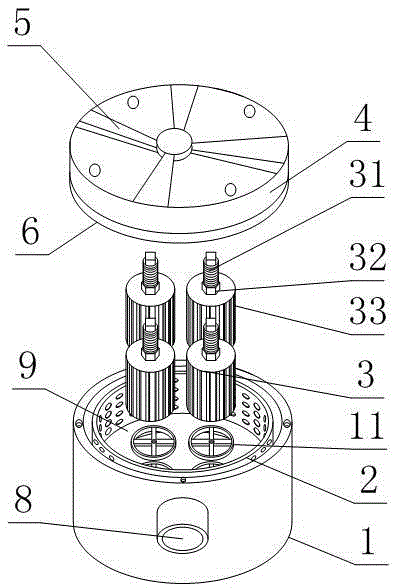

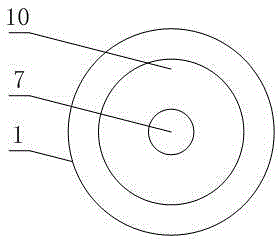

[0026] Such as figure 1 , a compressor muffler mechanism provided by the present invention comprises a barrel-shaped lower housing 1, an upper cover 4 is fixedly connected to the beginning end of the lower housing 1, and the upper cover 4 and the lower housing 1 enclose a muffler cavity 9 , the muffler cavity 9 is provided with a resistive muffler, the upper cover 4 or the lower housing 1 is also provided with an air outlet 7 and an air inlet 8 communicating with the muffler cavity 9, and also includes a cylindrical shape with multiple side walls. An inner cylinder 2 with a through hole, one end of the inner cylinder 2 is fixed on the bottom of the lower casing 1, the resistive noise-absorbing part includes a plurality of noise-absorbing barrels 3, the sound-absorbing barrels 3 are in the shape of a barrel with an open lower end, and its side is provided with A plurality of strip-shaped ribs 33 parallel to its axial direction, the left and right sides of the strip-shaped ribs ...

Embodiment 2

[0029] This embodiment is further limited on the basis of embodiment 1: as figure 1, the top of the sound-absorbing barrel 3 is provided with an internally threaded through hole, and a connecting screw 31 threadedly connected thereto is arranged in the internally threaded through-hole, and the upper and lower ends of the connecting screw 31 protrude respectively relative to the upper and lower ends of the sound-absorbing barrel The connecting screw 31 on the outside of the top of the sound-absorbing barrel 3 is provided with a nut 32 threadedly connected with the connecting screw 31. The sound-absorbing barrel interface 11 is a hole-like structure that runs through the bottom of the lower housing 1, and the hole-like structure is provided with The two ends of the rib connected with its inner wall are provided with a connecting screw hole, and the lower end of the connecting screw 31 is threadedly connected with the connecting screw hole.

[0030] The intersection of the hole s...

Embodiment 3

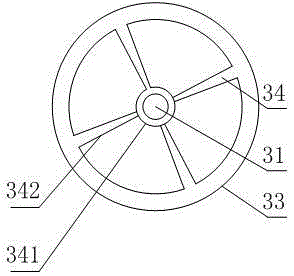

[0033] This embodiment is further limited on the basis of embodiment 1: as figure 1 and image 3 , the lower end of the sound-absorbing barrel 3 or its inner wall is provided with at least one rigidity cage 34 parallel to the radial direction of the sound-absorbing barrel 3, and the rigidity cage 34 includes a circular tube 341 and at least two connecting bars 342 , the two ends of the connection bar 342 are fixedly connected with the sound-absorbing bucket 3 and the circular pipe 341 respectively, and the connecting strips 342 are evenly distributed in a ring shape, the connecting screw 31 and the circular pipe 341 form a clearance fit, and the lower end of the sound-absorbing bucket 3 is still A sealing ring is provided.

[0034] In the above settings, there are gaps between adjacent connecting bars 342 for the circulation of gas in the inner cavity of the sound-absorbing bucket 3, and the circular tube 341 provided is used to reduce the span between the fulcrums of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com