A quantum cascade laser structure with high-efficiency lateral heat conduction and its preparation method

A quantum cascade and laser technology, which is applied in the direction of semiconductor lasers, semiconductor laser devices, lasers, etc., can solve the problems of the waveguide’s ability to limit the injection current, increase the laser waveguide loss, and increase the threshold current density. Problems such as improving electro-optic conversion efficiency, reduced injection current leakage, and reduced heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the following, the present invention will be further described by taking the quantum cascade laser with InGaAs / InAlAs / InP as the material system and silicon nitride as the insulating layer as an example, with reference to the drawings and specific implementation methods.

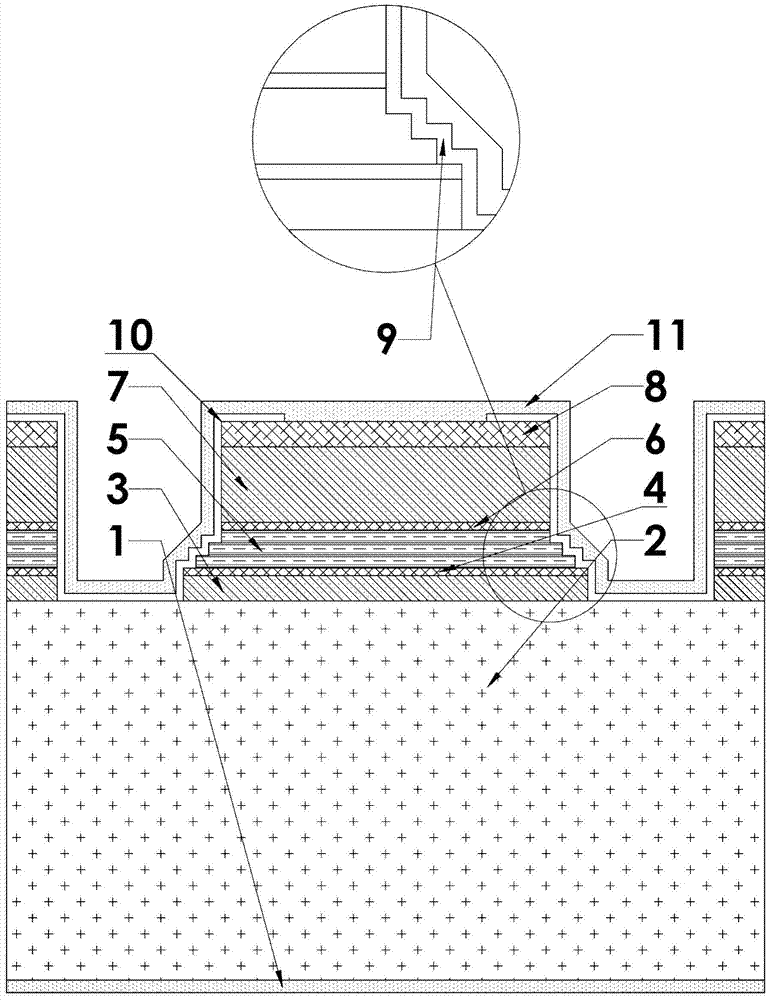

[0022] like figure 1 As shown, the structure of a quantum cascade laser with high-efficiency lateral heat conduction in the present invention is as follows from bottom to top: Au / Ge / Ni substrate surface electrode 1, N-type InP substrate 2, N-type InP lower cladding layer 3, N-type InGaAs lower waveguide layer 4, N-type InGaAs / InAlAs active region 5, N-type InGaAs upper waveguide layer 6, N-type InP upper cladding layer 7, N-type InP cap layer 8, Si 3 N 4 Electrical insulating layer 10 and Ti / Pt / Au epitaxial surface electrode 11. The number of steps in the stepped waveguide structure 9 is greater than or equal to one step, and in this embodiment, the number of steps is three steps. The height and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com