Laser emitter

A laser emission and laser tube technology, applied in the field of laser applications, can solve the problems of large volume, inconvenient use and manufacture, high power consumption, etc., achieve high thermal conductivity, reduce electromagnetic radiation, reduce power loss and loss of pulse high-frequency components Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

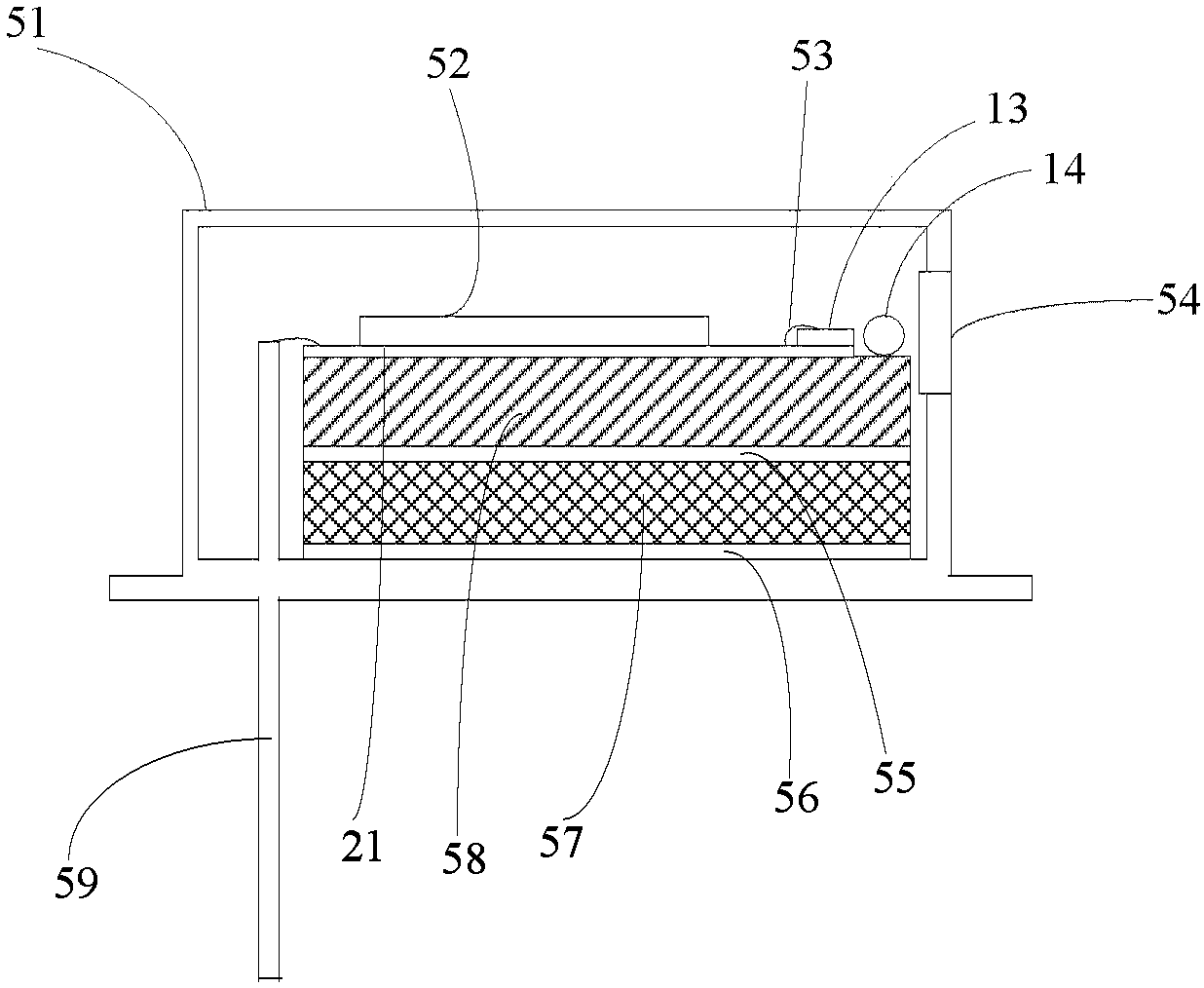

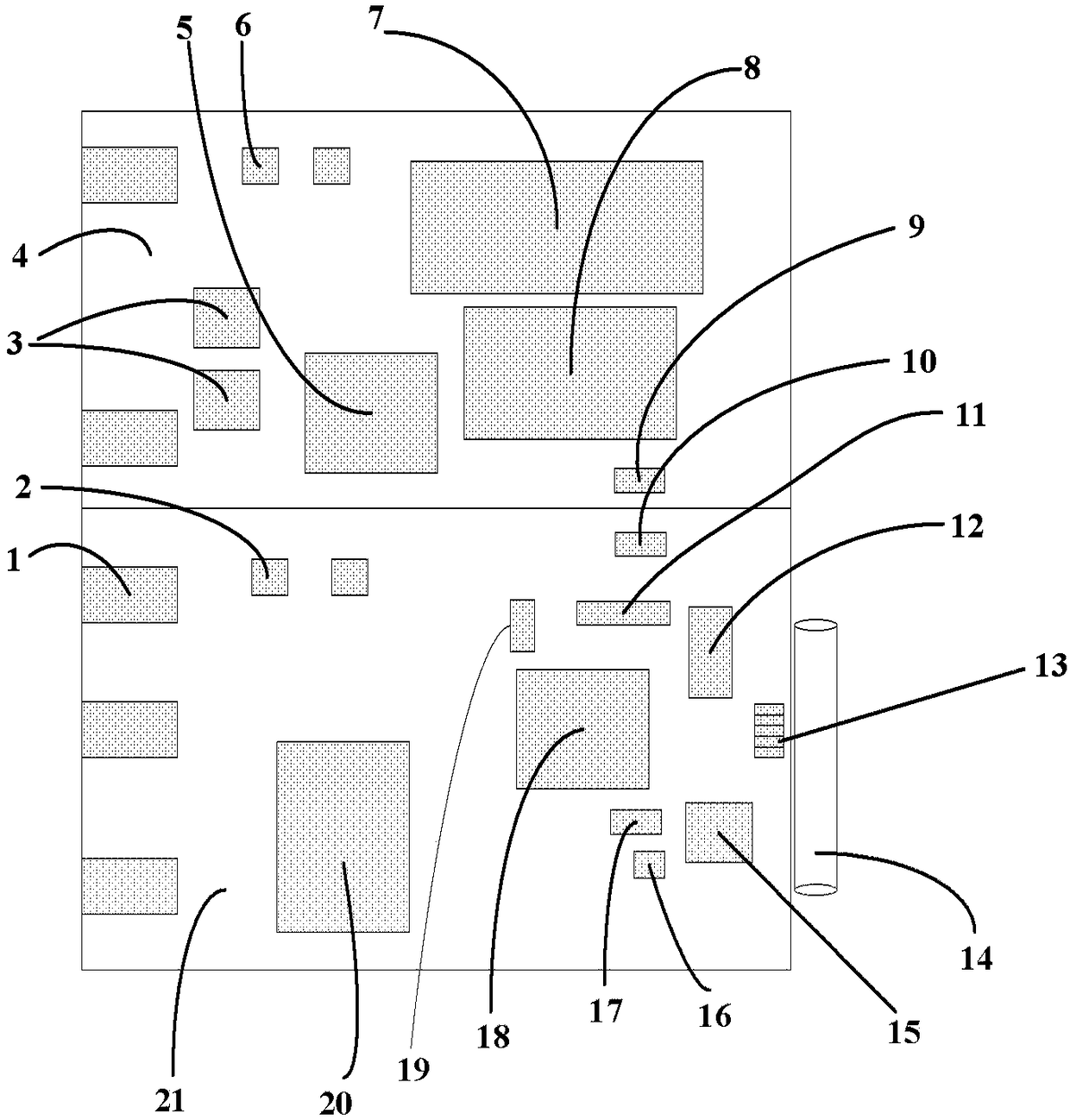

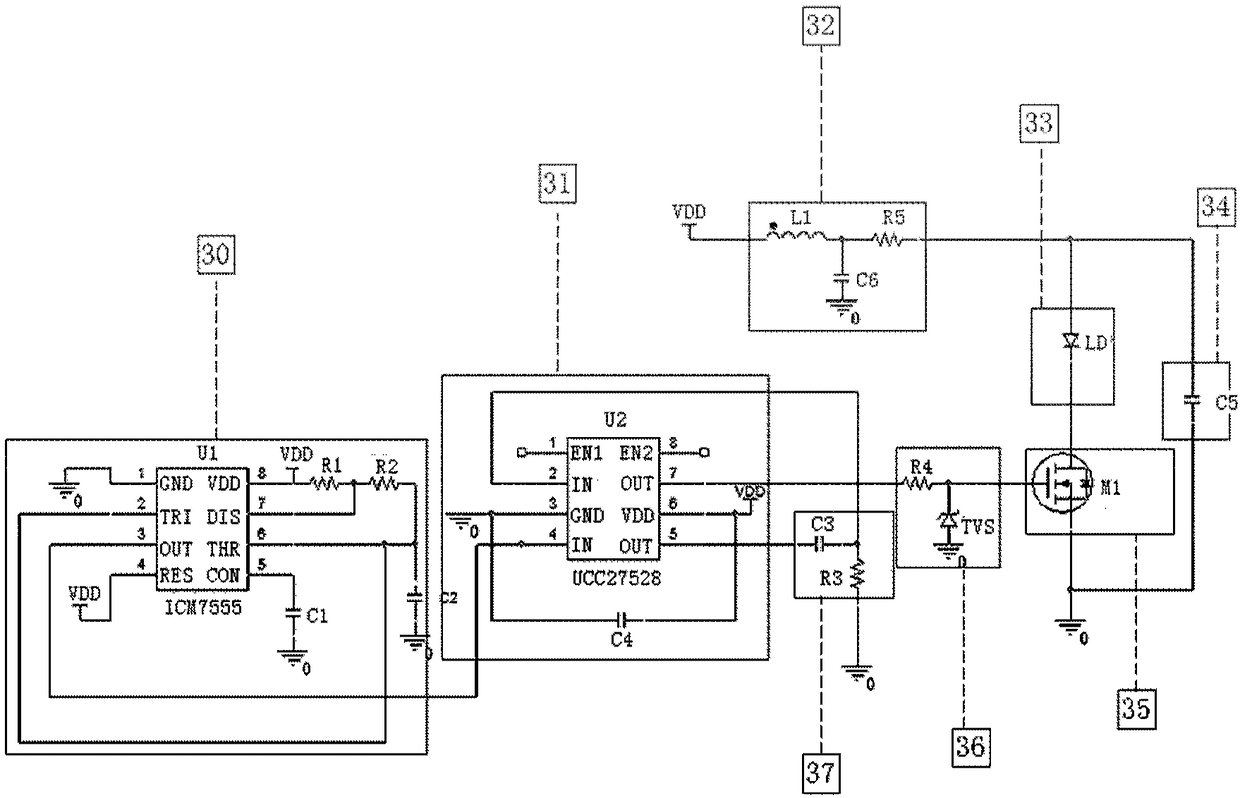

[0030] According to the basic idea of the present invention, the laser tube core and the laser driver are integrated on the aluminum nitride substrate with relatively high thermal conductivity to realize a high-current narrow-pulse laser emitting device, and the volume of the device is greatly reduced.

[0031] In the specification, the same or similar reference numerals designate the same or similar components. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

[0032] In the present invention, terms such as "disposed on", "attached to", "integrated on" include contact and non-contact with a single or multiple components.

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com