Uniform droplet/polymer space circuit combined printing device and method

A printing device and polymer technology, applied in the direction of additive manufacturing, 3D object support structure, manufacturing tools, etc., can solve the problem of difficult application of high-frequency space circuit printing, poor circuit smoothness and conductivity, and inability to use high-frequency circuit printing, etc. problems, to achieve the effect of improving molding quality and applicability, reducing parasitic impedance, improving line molding quality and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

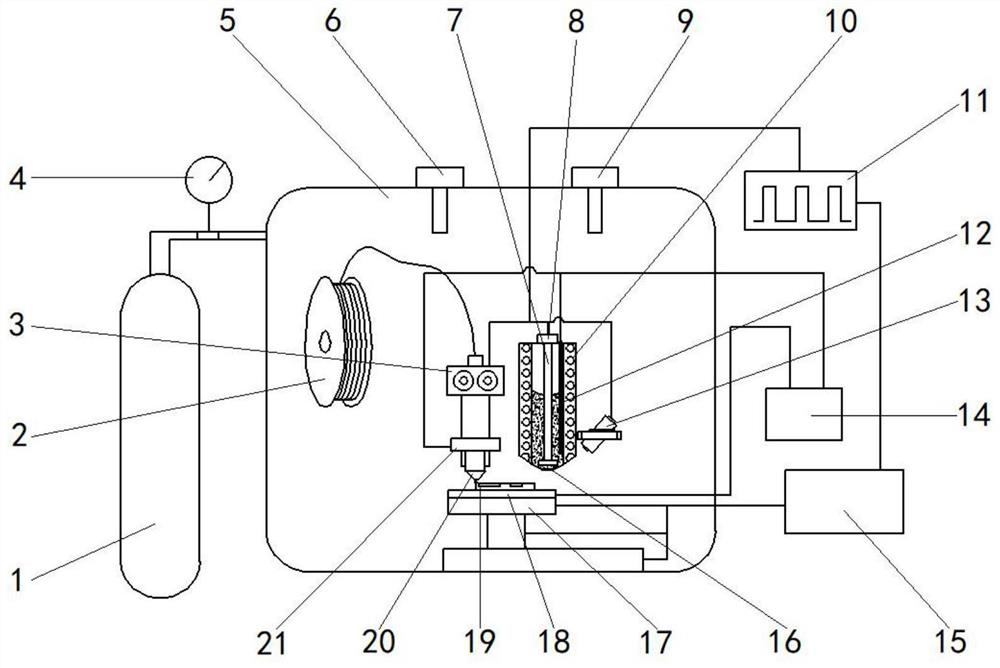

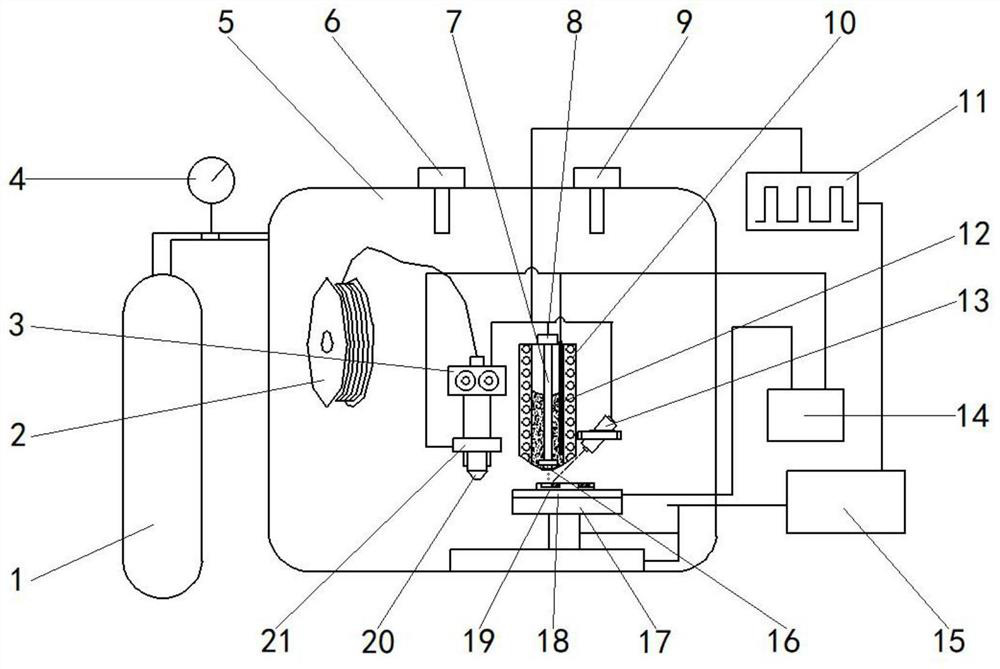

[0035] Embodiment 1: Printing of polyhedral space circuit functional parts. Firstly, the pressure reducing valve 4 is opened, and the glove box 5 is cleaned with the anti-oxidation inert gas cylinder 1 to ensure a low-oxygen working environment in the glove box 5 . Install the polyether ether ketone resin wire rod into the installation hole of the wire rod extruder 3, and put the tin-silver alloy material into the heating furnace 10, adjust the temperature controller 14, set the temperature of the heating furnace 10 to about 180°C, set the high The temperature of the molecular material heater 21 is about 350°C, and the temperature of the heated bed 18 is set at about 150°C. Carry out two-dimensional slicing processing on the space circuit model and generate the motion track information of the three-dimensional mobile platform 17 , the action time information of the wire extruder 3 , the exciting rod 7 and the laser 13 .

[0036] During the rapid manufacture of electronic circ...

Embodiment 2

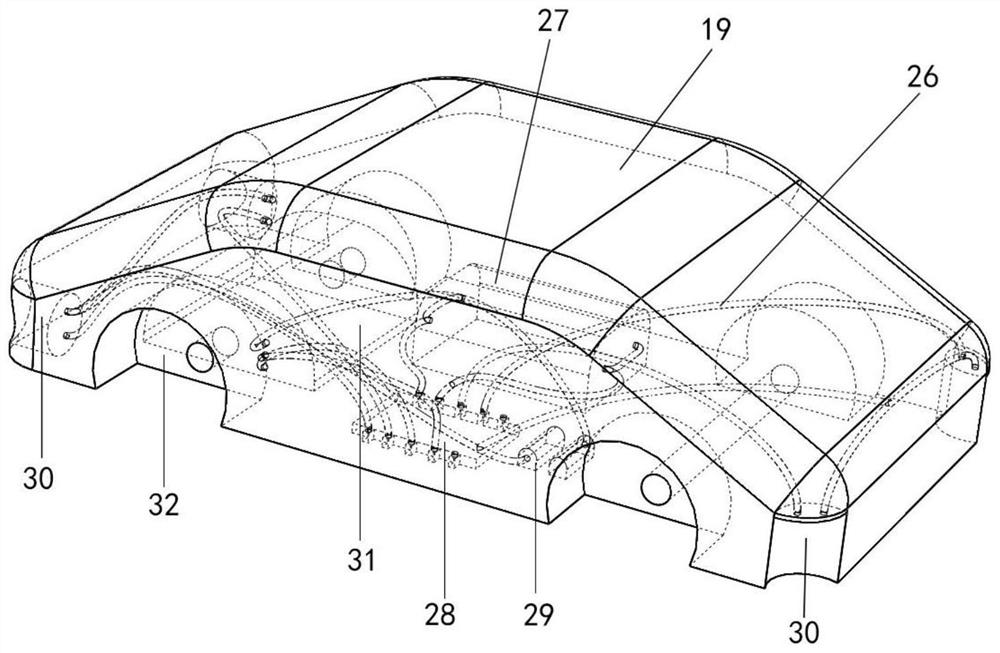

[0038] Example 2: Combined printing of multifunctional car model space circuit. The process steps of this embodiment are basically the same as those of Embodiment 1, except for the shape of the model and the way of internal wiring. Since the position of the light 30, the position of the motor 31 and the position of the wheel 32 of the trolley model are relatively fixed, they cannot be changed at will. Therefore, before printing the model, the layout of the model should be reasonably designed in the special space circuit modeling software. When the light position 30, the motor position 31 and the wheel position 32 interfere, the space for the power supply position 27, the control chip position 28 and the resistor position 29 is reserved, and then the circuit wires 26 are reasonably arranged inside the three-dimensional model to form the final three-dimensional data model . Import and read the generated deposition path file, and repeat the deposition according to the method of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com