Solid laser device

A technology of solid-state lasers and lasers, applied in the field of lasers, can solve the problems of low electro-optical conversion efficiency of lasers, and achieve high practical value, high reliability, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be explained and described in detail below in conjunction with the accompanying drawings.

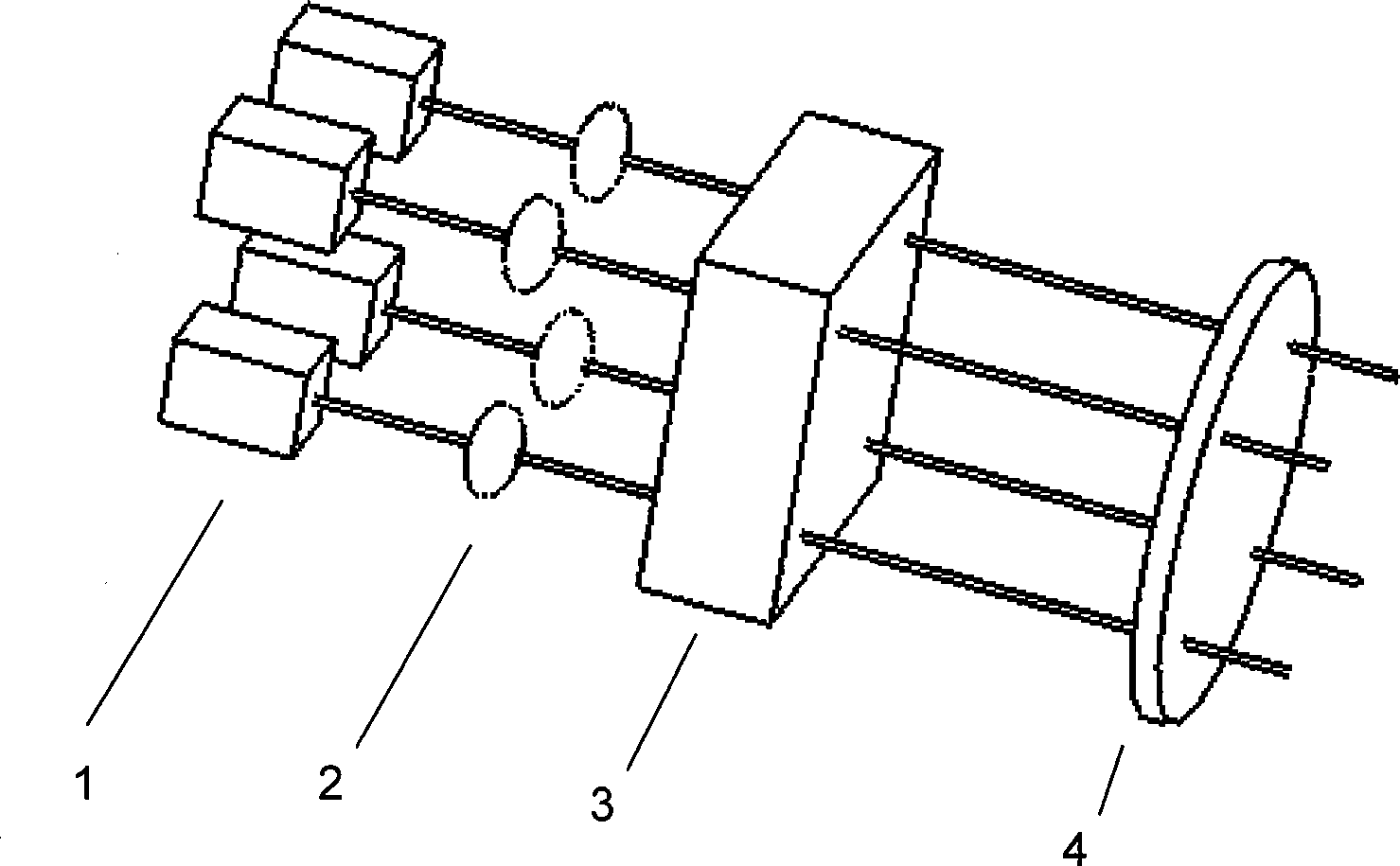

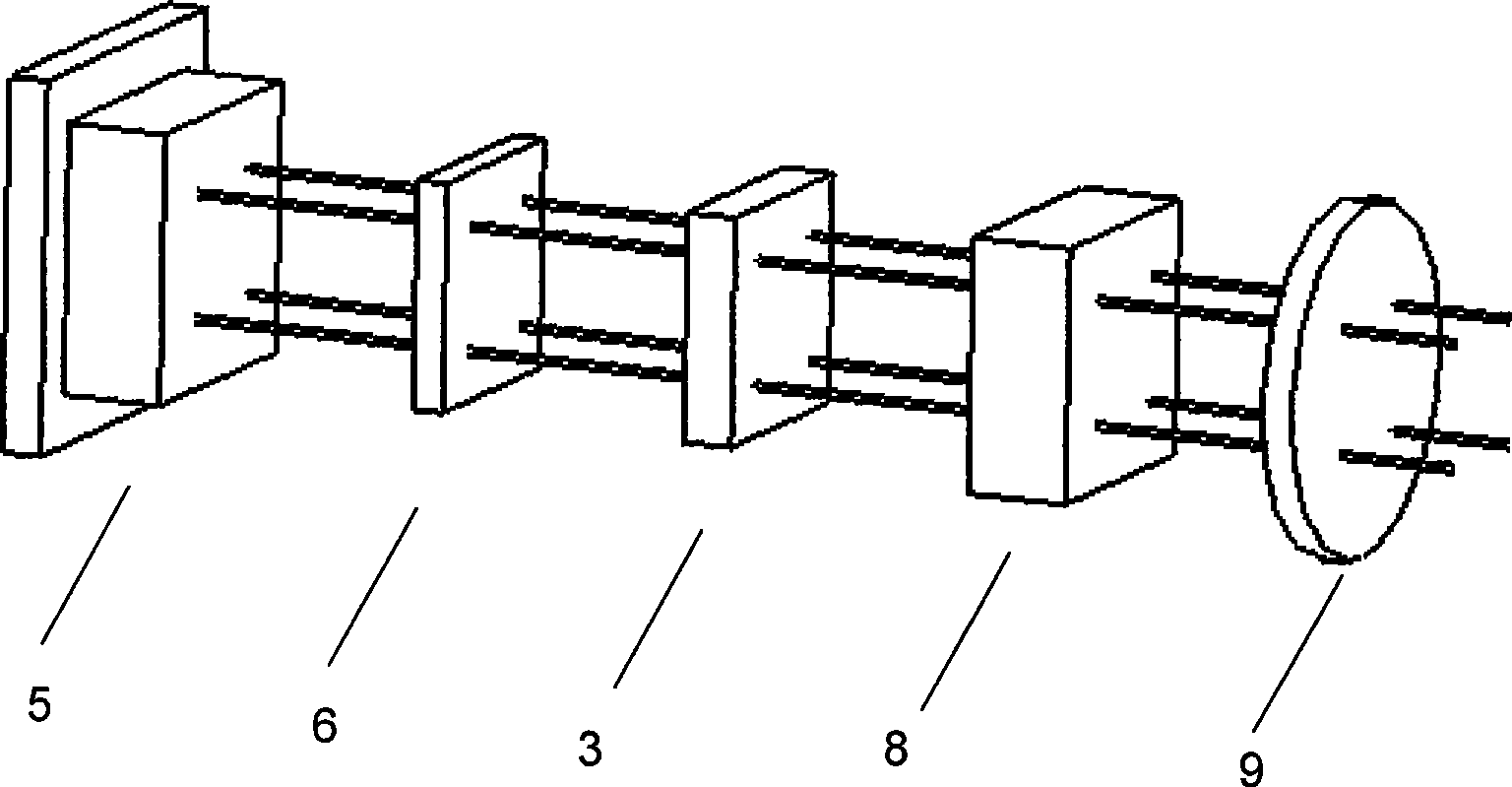

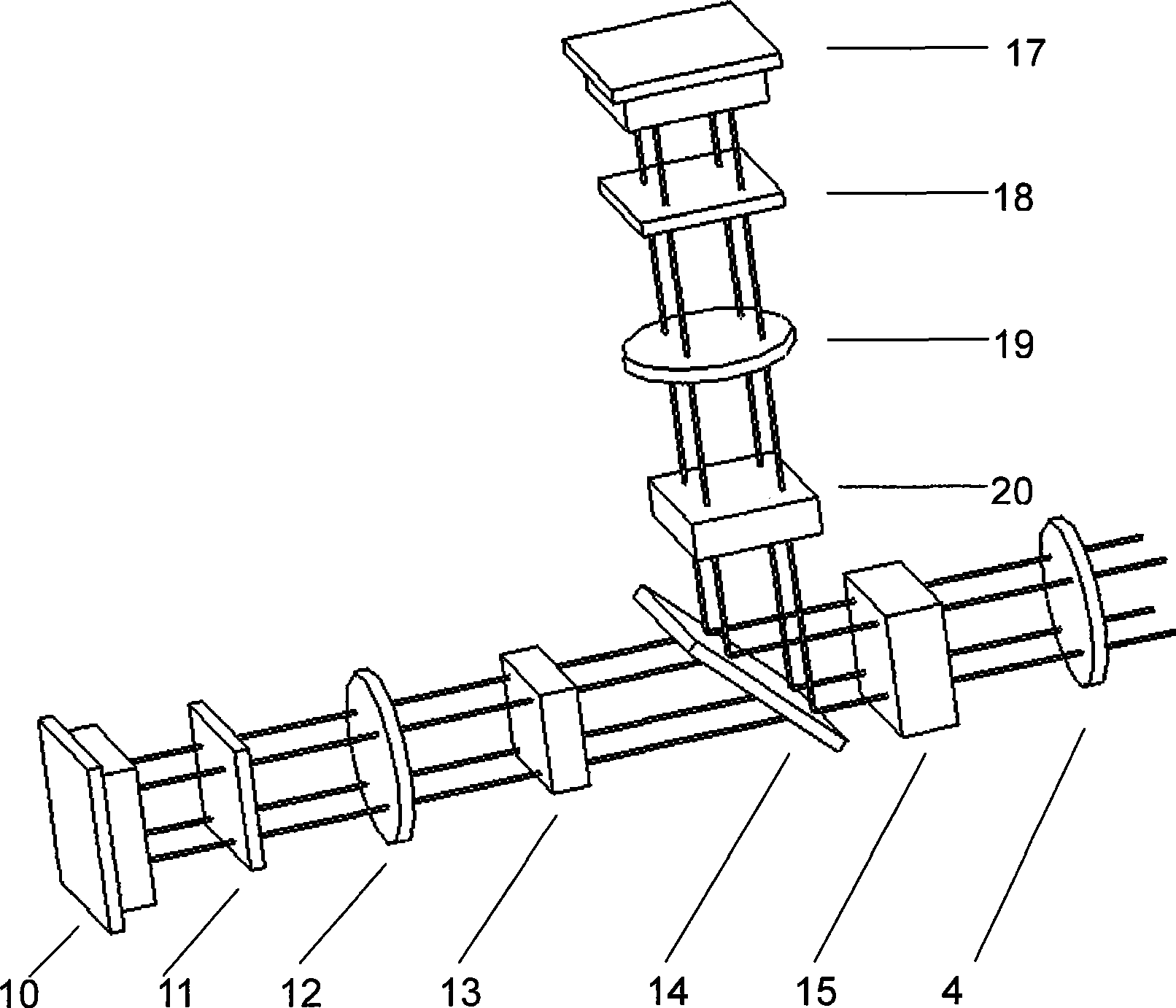

[0040] figure 1 It is a solid-state laser that outputs fundamental frequency light. Four semiconductor lasers 1 with an output wavelength of 808nm are selected to form a 2×2 semiconductor laser array. Each semiconductor laser 1 independently outputs pump light. An optical coupling device for coupling the pump light, corresponding to figure 1 In the embodiment of the present invention, the optical coupling device uses 2×2 independent coupling mirrors arranged in an array, and the coupling mirrors 2 in the array of coupling mirrors correspond to the lasers in the array of semiconductor lasers one by one, and the array of coupling mirrors A laser crystal 3 and a plane output mirror 4 are sequentially arranged on the output optical path. Among them, the laser wavelength emitted by the semiconductor laser array is 808nm, the two sides of all coupling mirro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com