Melt spinning cartridge

A melt-blown filter element and filter element technology, applied in the field of filter element, can solve the problems of land salinization, people's troubles, polluted river water, etc., and achieve the effects of strong dirt holding capacity, high cleanliness, and high filtration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

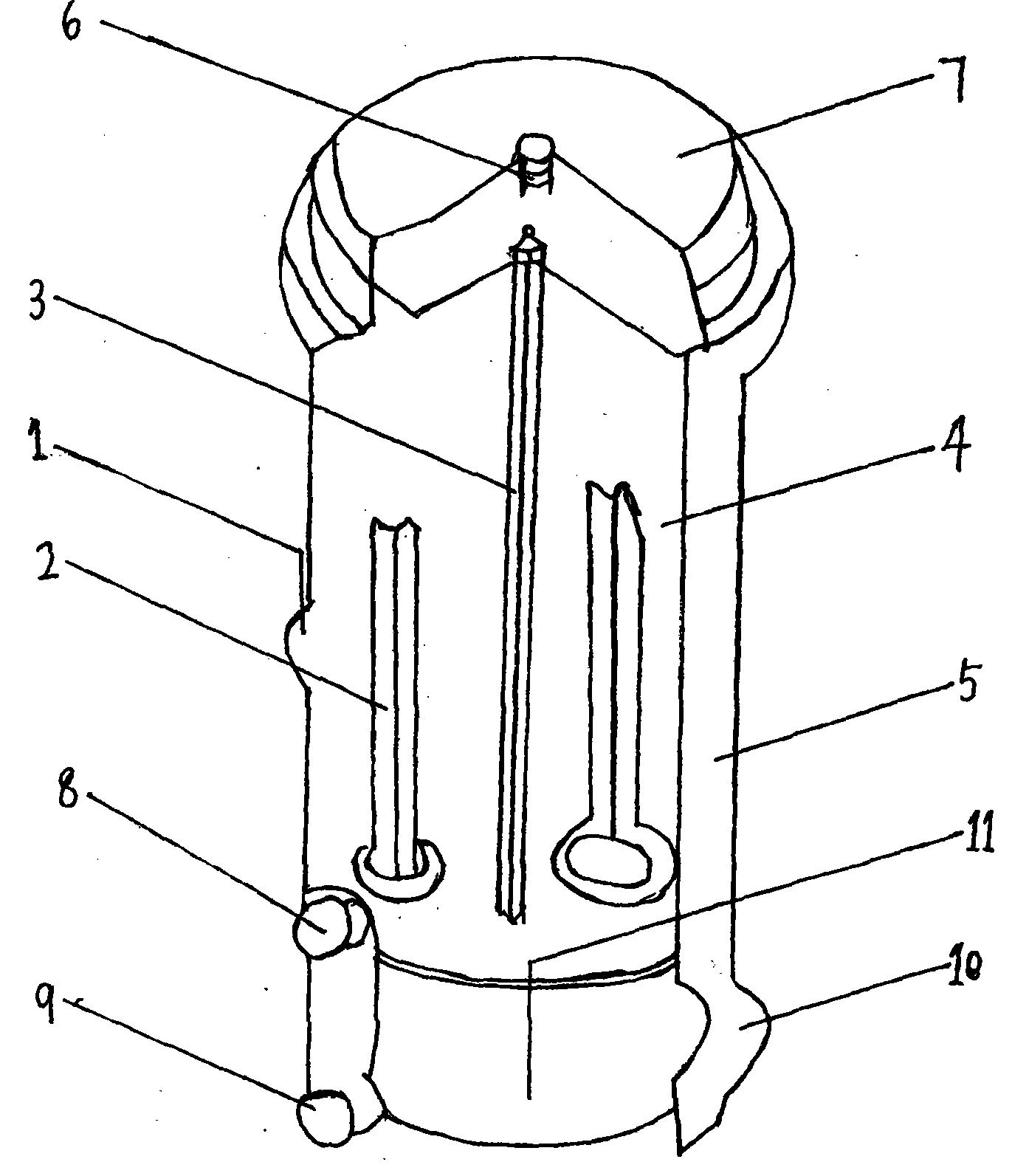

[0007] A melt-blown filter element, comprising an inlet 1, a guide rod 2, a center rod 3, a filter element 4, a casing 5, an exhaust port 6, a head 7, a sewage outlet 8, a vent 9, an outlet 10, and a lower head 11, The inlet 1 is located on the left side of the shell, the guide rod 2 is located between the center tie rod 3 and the inlet 1, the center tie rod 3 is provided with an exhaust port 6, the exhaust port 6 is located on the head 7, and the filter element 4 is located on the center tie rod 3 On the right side, the sewage outlet 6 is located under the inlet 1 on the left side of the shell, the vent 9 is located under the sewage outlet 8, and the outlet 10 is located above the lower head 11. Enter the air, pull the sewage through the center rod to enter the filter element for purification, and then the lower head seals the clean water and flows out from the outlet, while the impurities are discharged from the sewage outlet, and the air is discharged from the exhaust port. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com