Log high-pressure vacuum treatment device and method

A vacuum treatment, log technology, applied in the direction of pressure impregnation, etc., can solve the problem of material size limitation, and achieve the effect of simple technical operation and low contradiction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

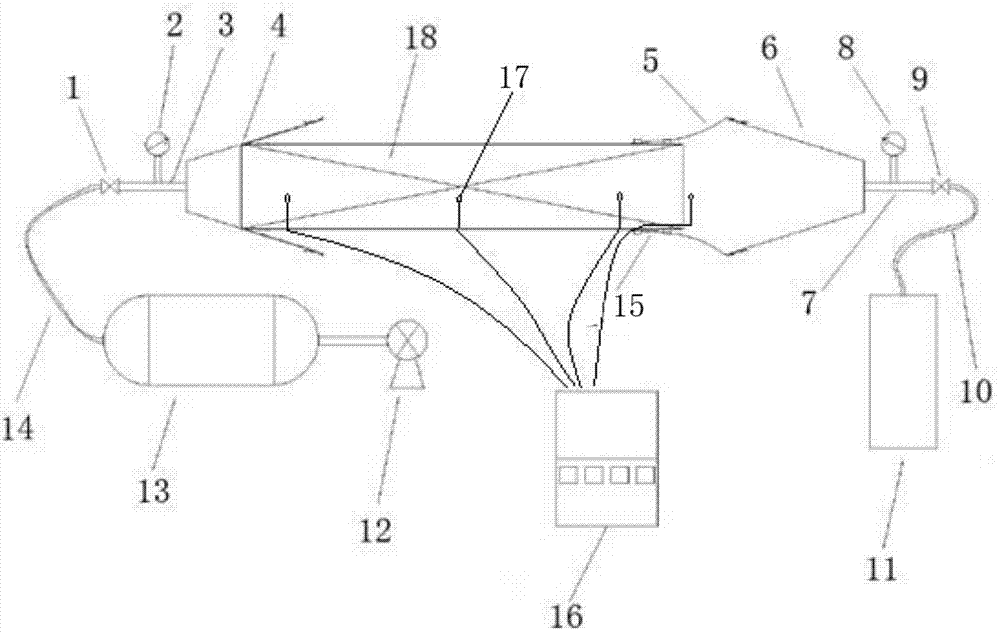

[0056] This implementation provides a log high-pressure vacuum processing equipment, its structure is as follows figure 1 shown. The equipment includes: gas sucker device, first stainless steel tube 3, second stainless steel tube 7, first rubber tube 14, second rubber tube 10, first valve 1, second valve 9, temperature sensor 17, first barometer 2. The second air pressure gauge 8, data measurement recorder 16, vacuum pump 12, vacuum buffer tank 13 and steam generator 11;

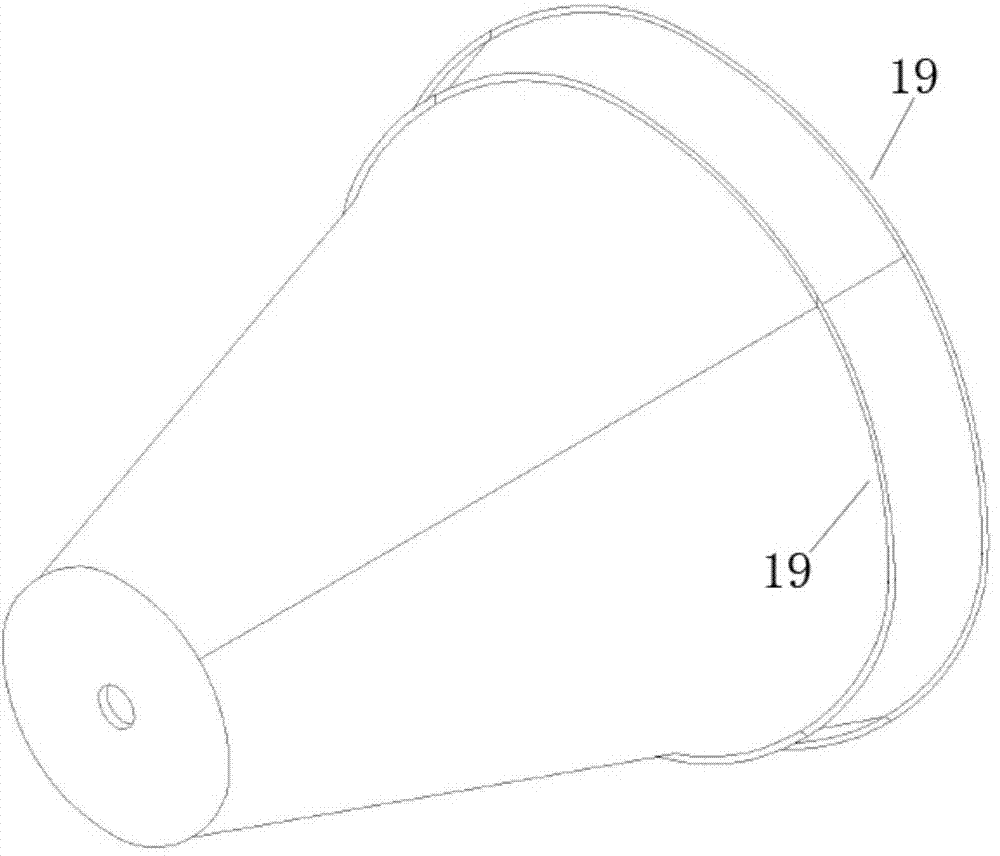

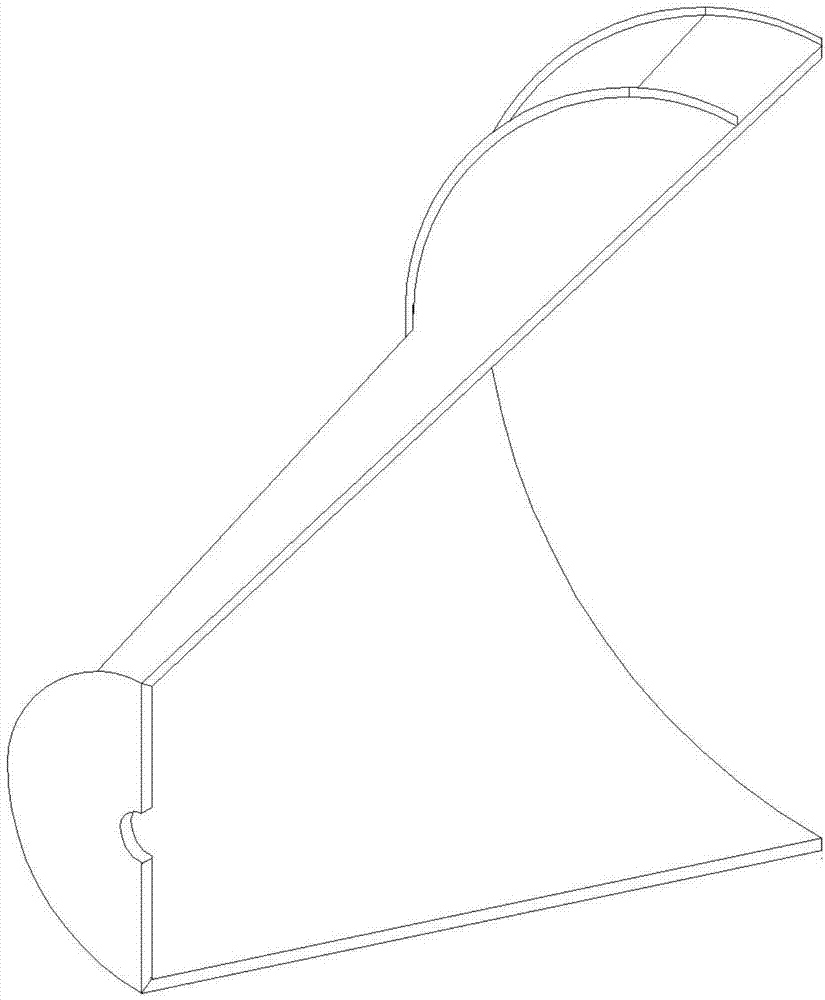

[0057] Wherein, the gas sucker device is composed of a first tapered stainless steel barrel 4, a second tapered stainless steel barrel 6, a first rubber sleeve with a small and large head, a rubber sleeve with a second small and large head 5, and a hoop pressure device 15;

[0058] One end of the second large and small head rubber sleeve 5 is sealingly connected with the opening of the second conical stainless steel barrel 6, and the other end is used to connect with the end of the log 18, and is fastened b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com