Vacuum coating machine sealing ring film coating tool and film coating method

A vacuum coating machine and sealing ring technology, which is applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problems of high cost and low processing efficiency of sealing rings, so as to increase the quantity and expand the processability Sealing ring size range, solve the effect of low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

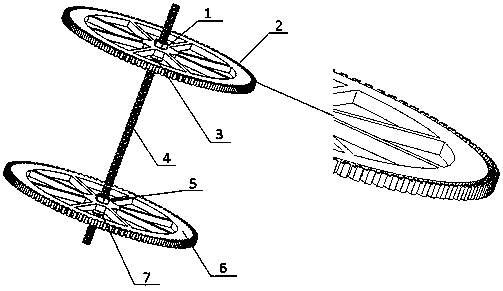

[0026] Such as figure 1 As shown, a sealing ring coating tool for a vacuum coating machine uses tooling a to coat the inner surface of the sealing ring. Tooling a includes a sealing ring hanging plate (upper hanging plate 2 and lower hanging plate 6), limit nuts, and screw rods 4 and the tightening nut, the limit nut includes the first limit nut 3 and the second limit nut 5, the tightening nut includes the first tightening nut 1 and the second tightening nut 7, and the screw rod 4 plays a role in connecting the hanging The function of the two hanging plates of the plate 2 and the lower hanging plate 6 is to cooperate with the limit nut and the tightening nut. Specifically, the outer circumferences of the upper hanging plate 2 and the lower hanging plate 6 are arranged with several protruding grooves. It is clamped and hung on the sealing ring, and the upper hanging plate 2 and the lower hanging plate 6 are connected together by the screw rod 4. The upper hanging plate 2 and th...

Embodiment 2

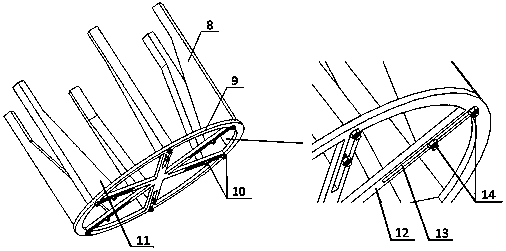

[0032] Such as figure 2As shown, a sealing ring coating tooling for a vacuum coating machine is used. Tooling b can be used to coat the outer surface of the sealing ring. It is composed of a support rod 8, a chassis 9 and a positioning nut 10. There are slideways 13 on the spokes 12, and the support rods 8 slide along the slideways 13 to adjust the relative position of the support rods 8. The support rods 8 are detachable. The rod 8 is not deformed due to the elastic effect of the sealing ring. The supporting rod 8 is used to support the sealing ring for clamping. Two studs 14 are installed at the lower end, which run through the slideway 13 and cooperate with the positioning nut 10 to fix the supporting rod 8 on the On the chassis 9; during processing, the tooling b rotates with the turntable of the vacuum chamber to ensure the uniformity of the coating.

[0033] A coating method for a sealing ring coating tooling for a vacuum coating machine, wherein the coating on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com