Novel GDX500 packing machine small box label paper glue cylinder assembly

A packaging machine and trademark paper technology, applied in packaging, transportation, packaging, labeling, etc., can solve problems such as poor glue quality, impact on folding quality, hidden glue dirt on glue holes, etc., and reduce the frequency of cleaning glue holes , Improve the quality of gluing, improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] Example 1

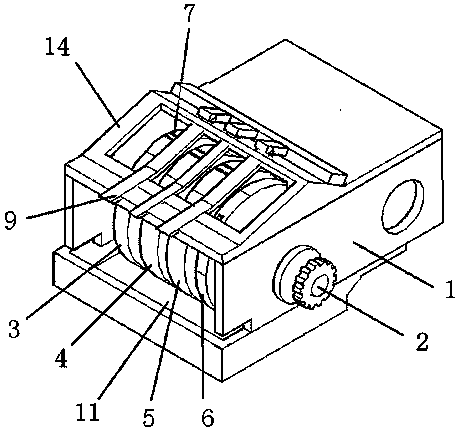

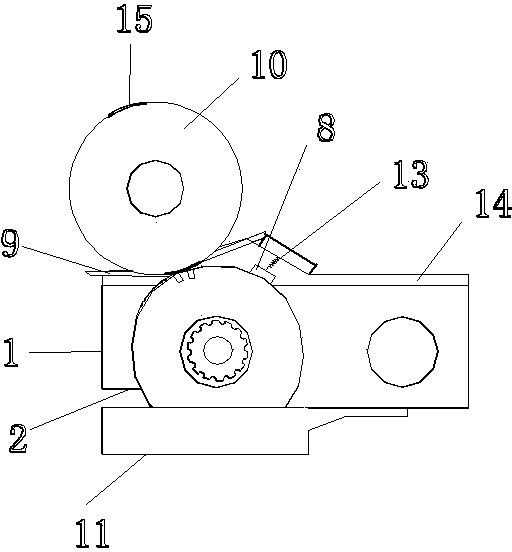

[0025] like Figure 1~5 As shown, the new GDX500 packaging machine small box trademark paper rubber cylinder assembly includes a bracket 1, a mandrel 2, an upper rubber wheel, a rubber hole 7, a scraper 8, a support rail 9, a contrasting roller 10, a rubber plate 11 and a top Cover 14.

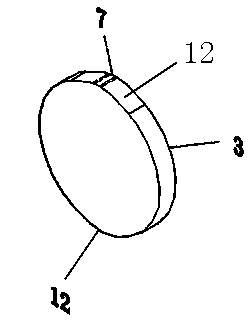

[0026] Described upper rubber wheel is provided with four, is divided into upper rubber wheel one 3, upper rubber wheel two 4, upper rubber wheel three 5, upper rubber wheel four 6, upper rubber wheel two 4 and upper rubber wheel three 5 have the same structure, The mandrel 2 is sequentially installed on the bracket 1 at intervals, the top of the bracket 1 is provided with a top cover 14 , and the bottom is provided with a rubber disc 11 . Just above every two upper rubber wheels spacing is provided with support guide rail 9, and support guide rail 9 is fixed on the top cover 14, and the bottom surface of upper rubber wheel is positioned at the glue liquid in the rubber ...

Example Embodiment

[0030] Example 2

[0031] The specific embodiment is the same as that in Embodiment 1, except that the glue hole 7 provided on the arc-shaped raised step 12 has a diameter of 1.4 mm and a depth of 0.8 mm. A rubber elastic body is provided on the contrasting roller 10 at a position opposite to the arc-shaped convex step 12 on the upper rubber wheel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap