Method for removing sodium in industrial alumina at high temperature

An industrial alumina and alumina technology, which is applied in the purification of aluminate/alumina/aluminum hydroxide, etc., can solve the problems that sodium in alumina cannot be effectively removed and the application range is narrow, so as to improve the competitiveness of enterprises, The process is simple and the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

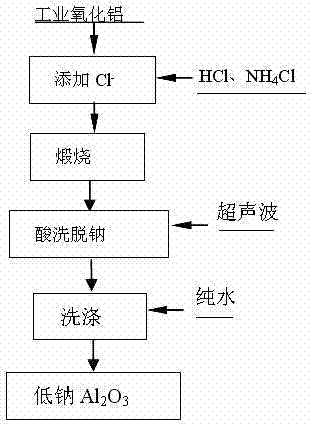

Image

Examples

Embodiment 1

[0021] 1) Weigh 100g of industrial alumina, put industrial alumina, hydrochloric acid and ammonium chloride into the container at a mass ratio of 100:3:3, and add corresponding water at the same time, the mass ratio of industrial alumina to water is 100:15, And mix well, put into the corundum crucible after mixing.

[0022] 2) Put the corundum crucible with the mixed industrial alumina into the electric furnace for calcination, the calcination temperature is 1100°C, keep it warm for 2 hours, and cool down to room temperature naturally.

[0023] 3) Wash the calcined industrial alumina under the ultrasonic field to remove Na, Ca, Mg and other elements remaining in the industrial alumina. The concentration of hydrochloric acid is 15g / l, the power of ultrasonic is 70 Hz, ammonium chloride 5g / l, liquid-solid mass ratio 3:1, washing temperature 60°C, washing twice and then filtering to obtain desodium alumina.

[0024] 4) The alumina after pickling-ultrasonic treatment was repeated...

Embodiment 2

[0026] 1) Weigh 100g of industrial alumina, put industrial alumina, hydrochloric acid and ammonium chloride into the container at a mass ratio of 100:4:4, and add corresponding water at the same time, the mass ratio of industrial alumina to water is 100:18, And mix well, put into the corundum crucible after mixing.

[0027] 2) Put the corundum crucible with the mixed industrial alumina into the electric furnace for calcination, the calcination temperature is 1200°C, keep it warm for 2.5h, and cool down to room temperature naturally.

[0028] 3) Wash the calcined industrial alumina under an ultrasonic field to remove Na, Ca, Mg and other elements remaining in the industrial alumina. The concentration of hydrochloric acid is 18g / l, the power of ultrasonic wave is 80 Hz, the ammonium chloride is 10g / l, the mass ratio of liquid to solid is 5:1, and the washing temperature is 70°C. After washing twice, filter to obtain desodium alumina.

[0029] 4) The alumina after pickling-ultra...

Embodiment 3

[0031] 1) Weigh 100g of industrial alumina, put industrial alumina, hydrochloric acid and ammonium chloride into the container at a mass ratio of 100:5:5, and add corresponding water at the same time, the mass ratio of industrial alumina to water is 100:20, And mix well, put into the corundum crucible after mixing.

[0032] 2) Put the corundum crucible with the mixed industrial alumina into the electric furnace for calcination, the calcination temperature is 1300°C, keep it warm for 3 hours, and cool down to room temperature naturally.

[0033] 3) Wash the calcined industrial alumina under an ultrasonic field to remove Na, Ca, Mg and other elements remaining in the industrial alumina. The concentration of hydrochloric acid is 25g / l, the power of ultrasonic wave is 90 Hz, the ammonium chloride is 15g / l, the mass ratio of liquid to solid is 6:1, and the washing temperature is 80°C. After washing twice, filter to obtain desodium alumina.

[0034] 4) The alumina after pickling-ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com