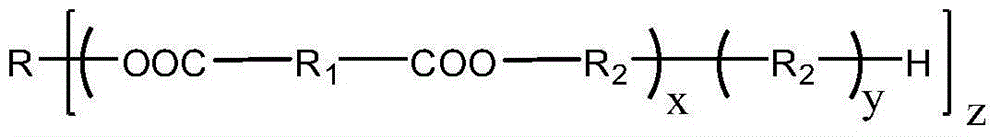

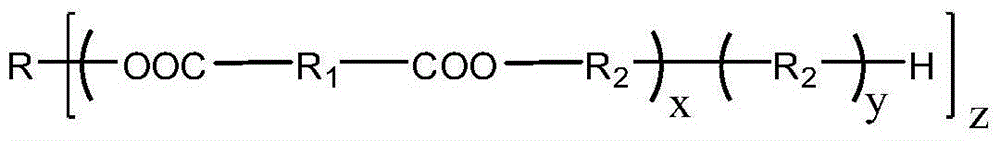

Polyurethane complex film adhesive and preparation method thereof

A laminating adhesive and polyurethane technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of low solid content of polyurethane laminating adhesives, poor metal composite adhesion, and poor hydrolysis resistance. , to achieve the effect of good compatibility, good wetting ability and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Put 20 parts of polyoxypropylene glycol with a hydroxyl value of 280 mg potassium hydroxide per gram, 0.01 part of zinc hexacyanocobaltate tert-butanol double metal complex, and 25 parts of phthalic anhydride into a 3L autoclave . Vacuumize twice and fill with nitrogen to normal pressure. When the temperature rises to 70°C, add propylene oxide. During the reaction, control the temperature at 110°C to 150°C. After adding 55 parts of propylene oxide, the pressure in the kettle is close to The normal pressure reaction was completed, and the whole reaction was polymerized for 4 hours. Then the unreacted propylene oxide was removed under vacuum to obtain the special polyol 1 with a functionality of 2 and a hydroxyl value of 57 mg potassium hydroxide / g.

Embodiment 2

[0046] Put 6.7 parts of trimethylolpropane, 0.015 parts of zinc hexacyanocobaltate ethylene glycol dimethyl ether bimetallic complex, and 40 parts of phthalic anhydride into a 3 L autoclave. Repeat vacuuming twice and fill with nitrogen to normal pressure. When the temperature rises to 70°C, add propylene oxide. During the reaction, control the temperature at 130°C to 180°C. After adding a total of 53.3 parts of propylene oxide, the pressure in the kettle is close to The normal pressure reaction was completed, and the whole reaction was polymerized for 5 hours. Then the unreacted propylene oxide was removed in vacuum to obtain the special polyol 2 with a functionality of 3 and a hydroxyl value of 85 mg potassium hydroxide / g.

Embodiment 3

[0048] Put 40 parts of diethylene glycol adipate with a molecular weight of 400, 0.015 parts of zinc hexacyanocobaltate tert-butanol double metal complex, and 20 parts of succinic anhydride into a 3L autoclave. Vacuumize twice and fill with nitrogen to normal pressure. When the temperature rises to 70°C, add propylene oxide. During the reaction, control the temperature at 110°C to 150°C. After adding a total of 40 parts of propylene oxide, the pressure in the kettle is close to The normal pressure reaction was completed, and the whole reaction was polymerized for 5 hours. Then the unreacted propylene oxide was removed under vacuum to obtain the special polyol 3 with a functionality of 2 and a hydroxyl value of 112 mg potassium hydroxide / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com