Seaweed biological dry land film

A mulching, biological technology, applied in the direction of fertilizer mixture, application, organic fertilizer, etc., to achieve the effect of promoting plant growth, good water retention performance, and reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

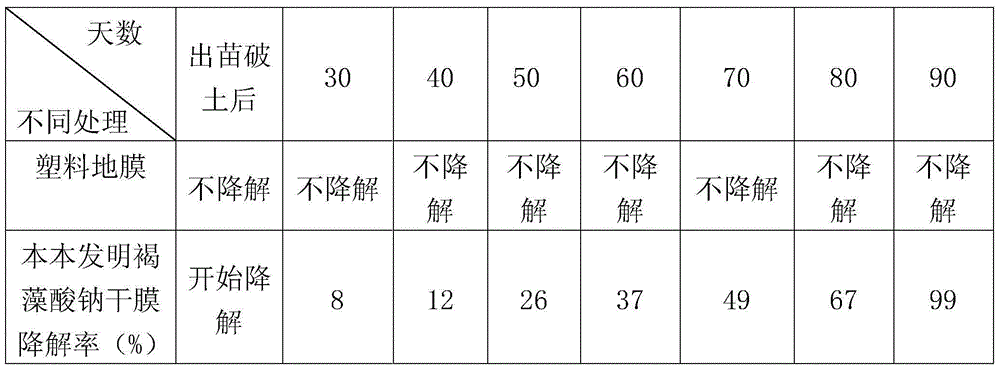

Embodiment 1

[0032] Weigh 15kg of sodium alginate with a viscosity of 0.3Pas, add 1000Kg of 65°C water to dissolve it for 2 hours, degas it in vacuum for 4 hours, and spread the film evenly on a stainless steel plate (or plexiglass plate). The wet film thickness is controlled at 0.05mm. Dry at 120°C for 40 minutes, so that the water content of the obtained sodium alginate film reaches 10%, and then the sodium alginate film is immersed in boric acid with a mass percentage of 0.5%, calcium lactate with a mass percentage of 5%, and hexametaphosphate with a mass percentage of In the 0.05% mixed solution, the pH of the solution is 5.3, and the cross-linking reaction is carried out for 30 minutes, then washed with tap water, and dried at 120°C for 20 minutes to obtain 15.72Kg of fully degraded seaweed bio-dried mulch film.

[0033] The technical indicators of the obtained dry film: moisture content 8.62%; organic matter 91.21%; thickness 0.011mm; water absorption rate less than 28.1%; elongation ...

Embodiment 2

[0035] Weigh 12kg of sodium alginate with a viscosity of 0.7 Pas, add 1000Kg of 65°C water to dissolve it for 2 hours, degas it in vacuum for 2 hours, and spread the film evenly on a stainless steel plate (or plexiglass plate). The wet film thickness is controlled at 0.04mm. Drying at 65°C for 3 hours, the water content of the obtained sodium alginate film reached 16.2%, and then the sodium alginate film was immersed in boric acid with a mass percentage of 0.5%, calcium citrate with a mass percentage of 8%, and hexametaphosphate with a mass percentage of In the 0.2% mixed solution, the pH of the solution is 4.8, and the cross-linking reaction is carried out for 30 minutes, then washed with tap water, and dried at a low temperature of 65°C for 2 hours to obtain 12.3Kg of fully degraded seaweed bio-dried mulch film.

[0036] The technical indicators of the obtained dry film: moisture content 9.24%; organic matter 90.74%; thickness 0.011mm; water absorption rate less than 25.6%; e...

Embodiment 3

[0038] Weigh 14kg of potassium alginate with a viscosity of 0.5 Pas, add 1000Kg of 65°C water to dissolve it for 2 hours, degas it in vacuum for 4.5 hours, and spread the film evenly on a stainless steel plate (or plexiglass plate). The wet film thickness is controlled at 0.03mm. Dry at 100°C for 1.5 hours, so that the water content of the obtained potassium alginate film reaches 26.3%, and then the potassium alginate film is immersed in boric acid with a mass percentage of 0.5%, calcium gluconate with a mass percentage of 8%, and hexametaphosphate. In a 1.5% mixed solution, the pH of the solution is 4.6, and the cross-linking reaction is carried out for 40 minutes, then washed with tap water, and dried at 100°C for 1 hour to obtain 14.6Kg of fully degraded seaweed bio-dried mulch film.

[0039] The technical indicators of the obtained dry film: moisture content 10.08%; organic matter 91.14%; thickness 0.014mm; water absorption rate less than 24.7%; elongation rate 8.35%; light...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap