Inclined stone material dry-hanging structure and construction method thereof

A technology for dry hanging of stone and stone, applied in building components, building structure, processing of building materials, etc., can solve the problem of unsuitable installation of inclined stone slabs, large stress between hanging parts and stone slabs, and affecting the installation position of stone slabs. and other problems, to achieve the effect of convenient replacement, wide application range and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

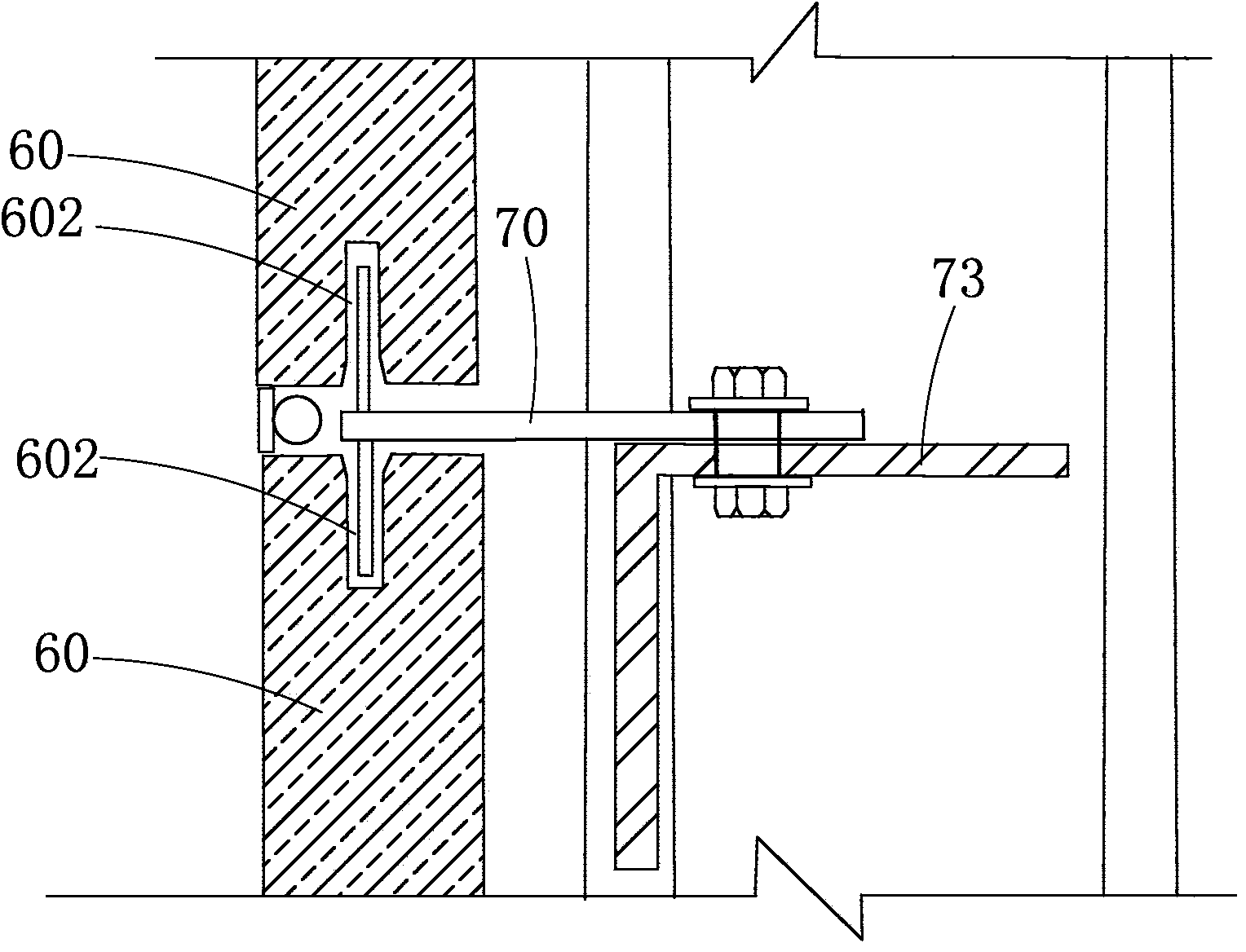

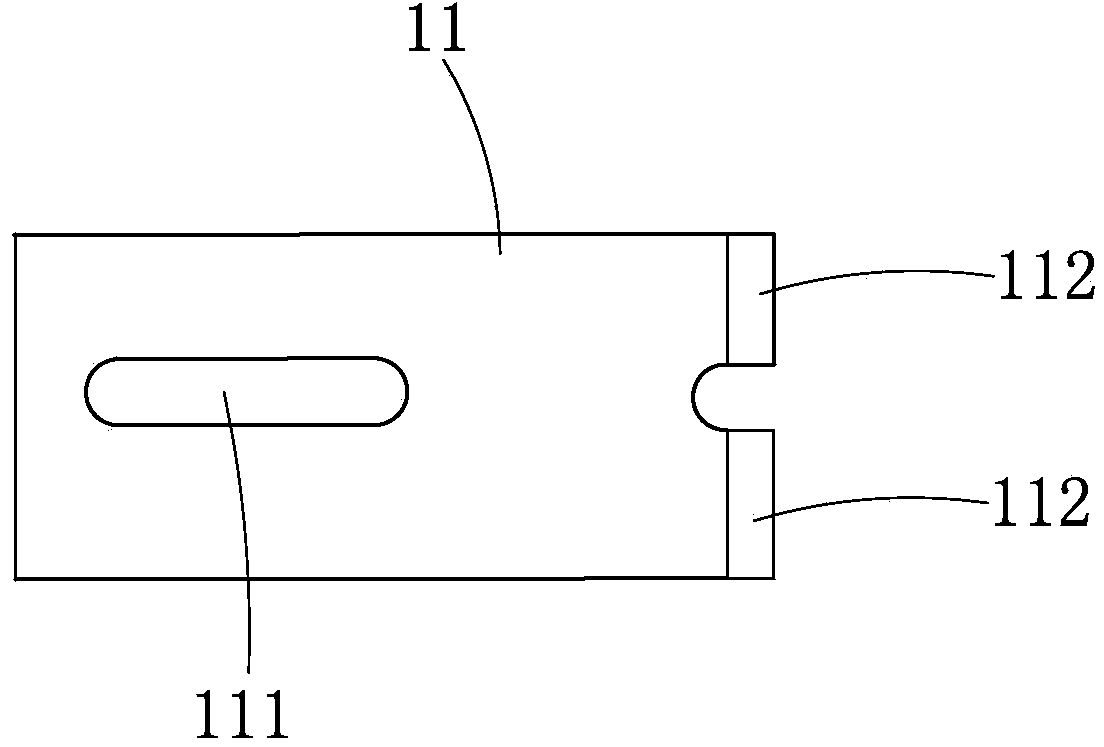

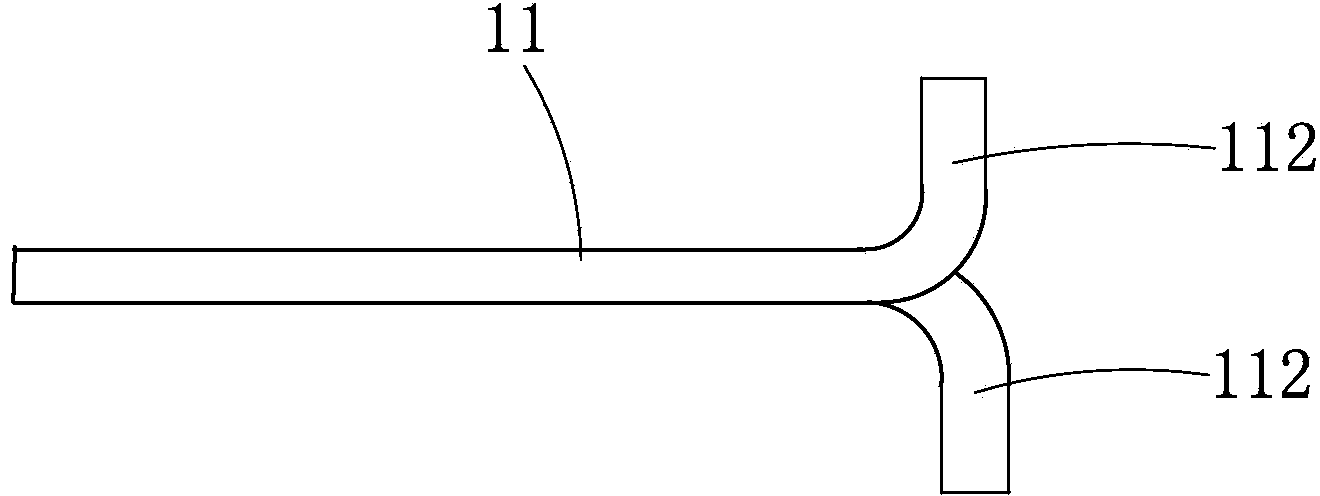

[0042] Such as Figure 6 As shown, an inclined stone dry-hanging structure of the present invention includes a plurality of inclined stone plates 60, a main body steel frame 3, a single hook code 13 supporting the bottom edge of the stone plate 60 and connecting the side of the stone plate 60 with the main body steel The stone dry-hanging adjustable assembly of skeleton 3. The inclination of the stone plate 60 relative to the facade is less than 15°, the installation height is not more than 30m from the ground, and the thickness is not less than 20mm. Short grooves 601 are provided on the bottom and sides, and the short grooves 601 are filled with stone materials. Structural glue, when the code feet of the single hook code 13 and the double hook code 11 are clamped in the short groove 601, it plays a further fixing role. The groove depth of the short groove 601 at the bottom of the stone board 60 is less than 20 mm, and the groove depth of the short groove 601 at the side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com