Multifunctional combined type concrete lining trolley

A lining trolley and combined technology, applied in the shaft lining, tunnel lining, underground chamber, etc., can solve the problems of single section, unsatisfactory, simple structure, etc., and achieve large section span, high overall stability, and easy operation flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

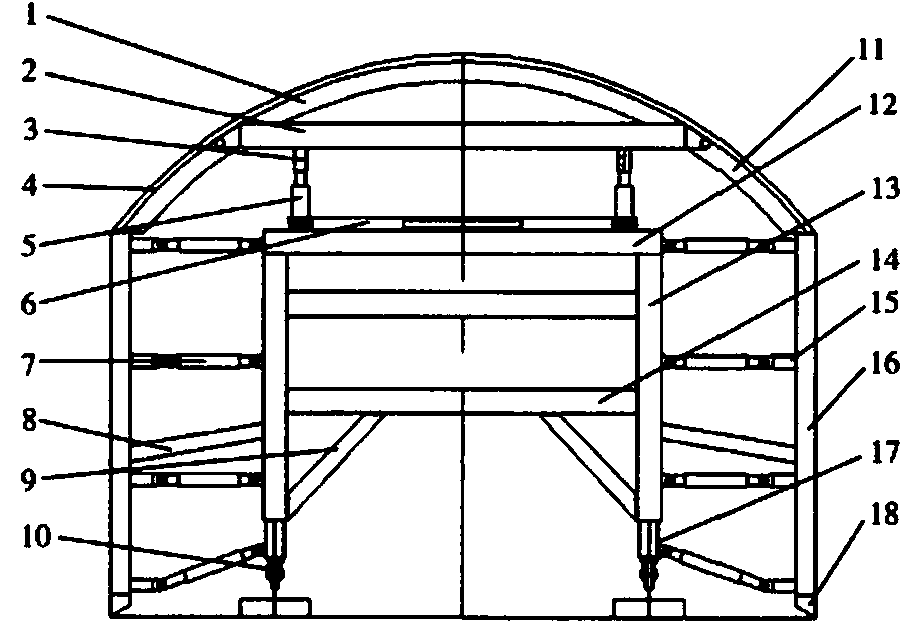

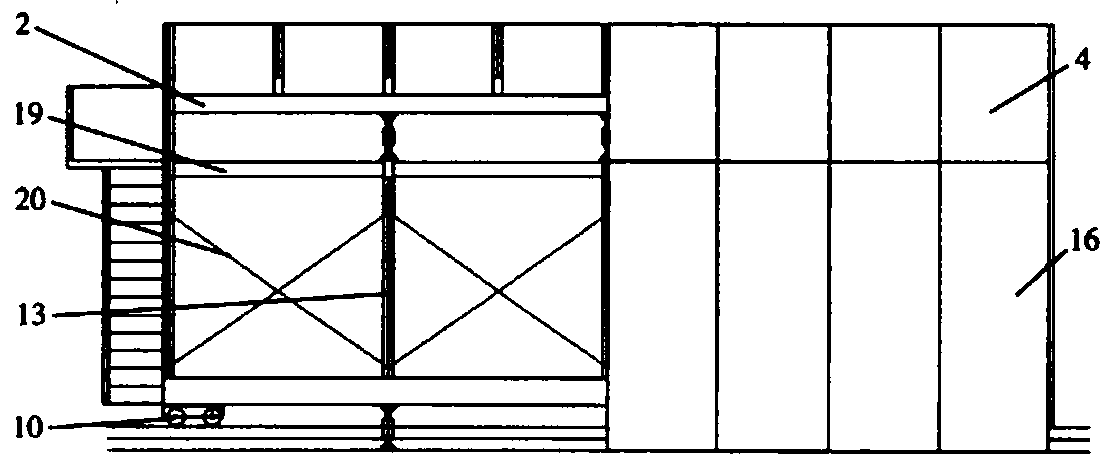

[0015] The multifunctional combined concrete lining trolley of the present invention is composed of three main parts and two auxiliary parts. The 3 main parts include formwork system, hydraulic support and demoulding system and electric walking system; the 2 auxiliary parts include automatic measuring system and vibrating system. The trolley has sufficient rigidity, strength and overall stability, which can ensure the geometric size and shape of the engineering structure, and the operation is flexible and reliable, and easy to control.

[0016] The formwork system is composed of formwork, columns, arches, and door frames, and its main function is structural skeleton and forming.

[0017] (1) Mast frame: It is composed of lower longitudinal beams, upper longitudinal beams, lower beams, upper beams and scissors braces, etc., which are connected by bolts. straight load. The mast is made of H-shaped steel, which has the characteristics of large load capacity, high strength, high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com