Bearing of a rocker arm for a valve train of an internal combustion engine

A technology of valve actuators and support devices, which is applied in the direction of valve devices, machines/engines, mechanical equipment, etc., can solve the problems of large installation space, disadvantages, etc., and achieve good lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

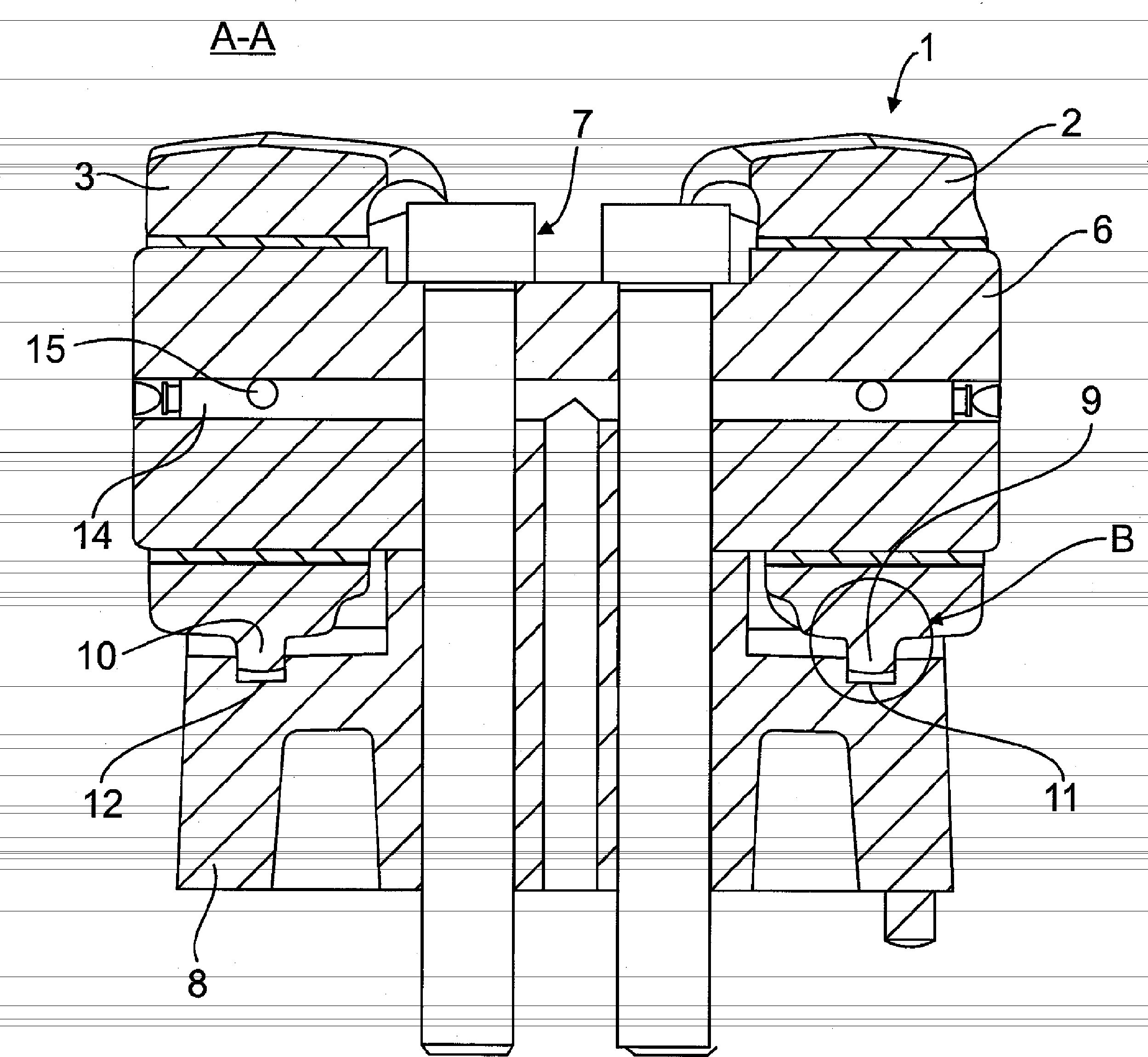

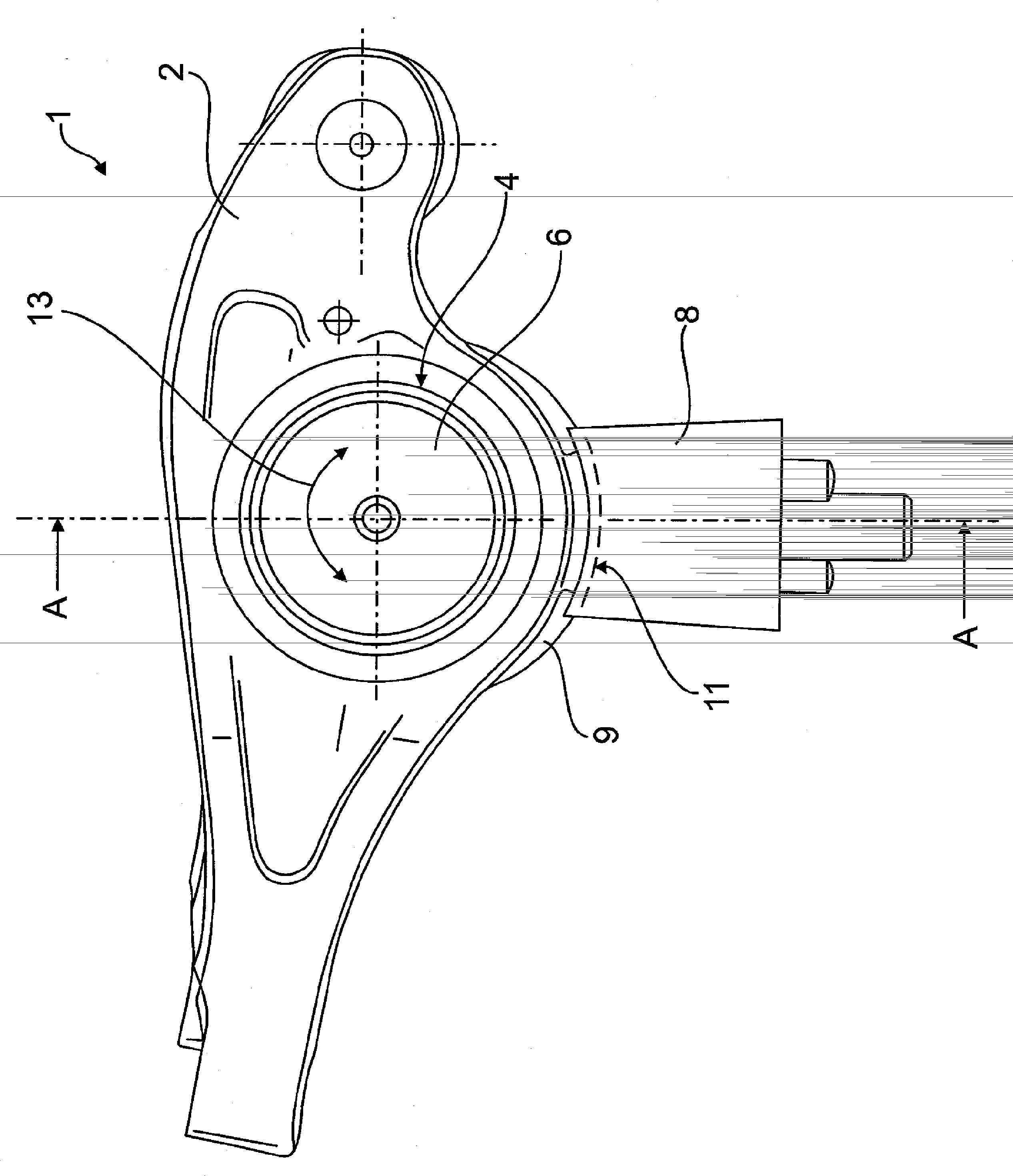

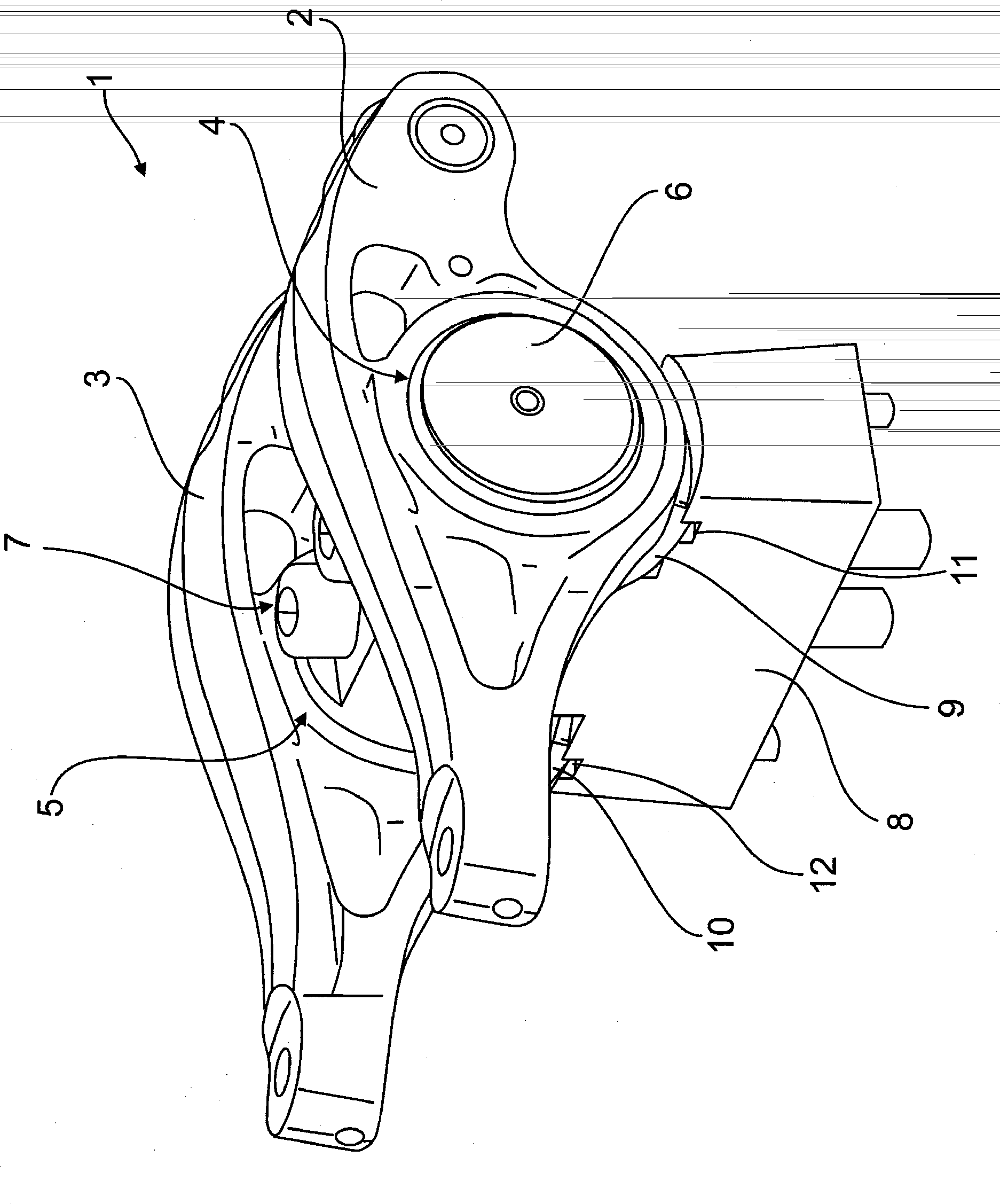

[0026] exist figure 1 3 shows a pivoting lever arrangement 1 with two pivoting levers 2 , 3 , which are each pivoted laterally onto a shaft 6 with bore holes 4 , 5 . The shaft 6 is fastened with screws 7 to a bearing block 8 which itself extends laterally below the area of the tilting levers 2 , 3 .

[0027] For axial positional security of the pivoting levers 2 , 3 , a protruding insert element is formed on these pivoting levers, pointing toward the bearing block. These insert elements are designed as ring web parts 9 , 10 and are tongue elements of a tongue-and-groove connection. The groove elements as counter elements are cut out on the one-piece support block 8 as annular groove parts 11 , 12 , for example by milling.

[0028] especially by figure 2 It can be seen from the side view that the ring web parts 9 , 10 extend laterally beyond the area of the bearing block 8 to such an extent that the ring web parts 9 , 10 and The axial side supports between the associat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com