Hydro-pneumatic spring suspension cylinder

A technology of suspension oil cylinder and oil and gas spring, applied in the direction of spring, spring/shock absorber, gas-liquid shock absorber, etc., can solve the problems of difficult vehicle layout, large size of accumulator, complicated structure, etc., to improve working conditions Adaptability and ride comfort, ease of manufacture and maintenance, compact and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail in conjunction with the following examples (accompanying drawings):

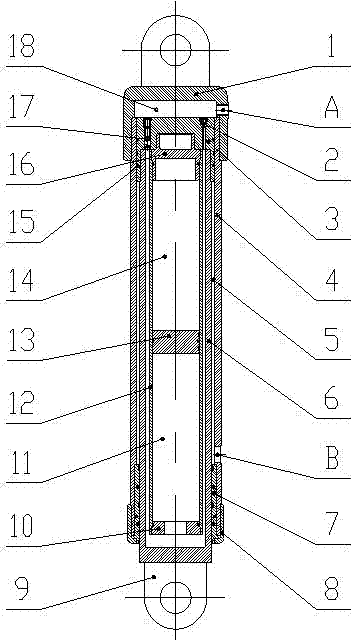

[0015] as attached figure 1 As shown, the oil-gas spring suspension oil cylinder of the present invention is mainly composed of an upper coupling body 1, a damping hole 2, a main piston 3, a cylinder barrel 4, a piston rod 6, a guide sleeve 7, a large nut 8, a lower coupling body 9, a lower seat 10, The cylinder 12, the floating piston 13, the seal ring 15, the upper seat 16 and the one-way valve 17 are composed, wherein the piston rod 6 is a hollow structure, and a guide sleeve 7 is arranged on the outside of the hollow piston rod. Four spaces, main oil chamber 18, auxiliary oil chamber 11, piston rod chamber oil chamber 5 and air chamber 14, are formed inside the oil cylinder.

[0016] The main oil chamber 18 is a space surrounded by the main piston 3, the cylinder barrel 4 and the upper coupling body 1. The main piston 3 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com