Automatic lead inserting device of combined fireworks

A combination of fireworks and automatic technology, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of launch failure, prone to failure, low production efficiency, etc., achieve accuracy and reliability improvement, reliable and accurate fire transmission and ignition, The effect of increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

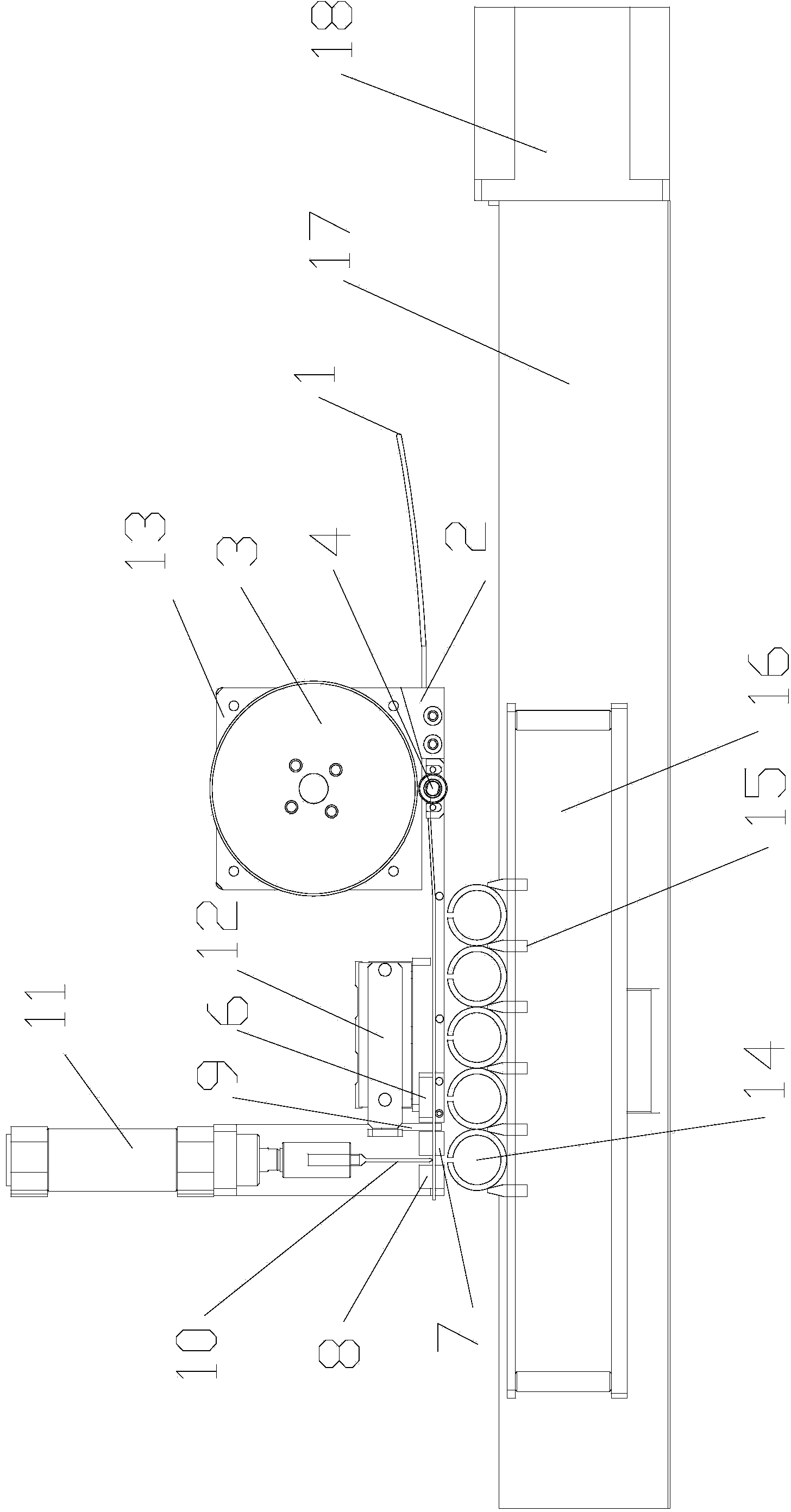

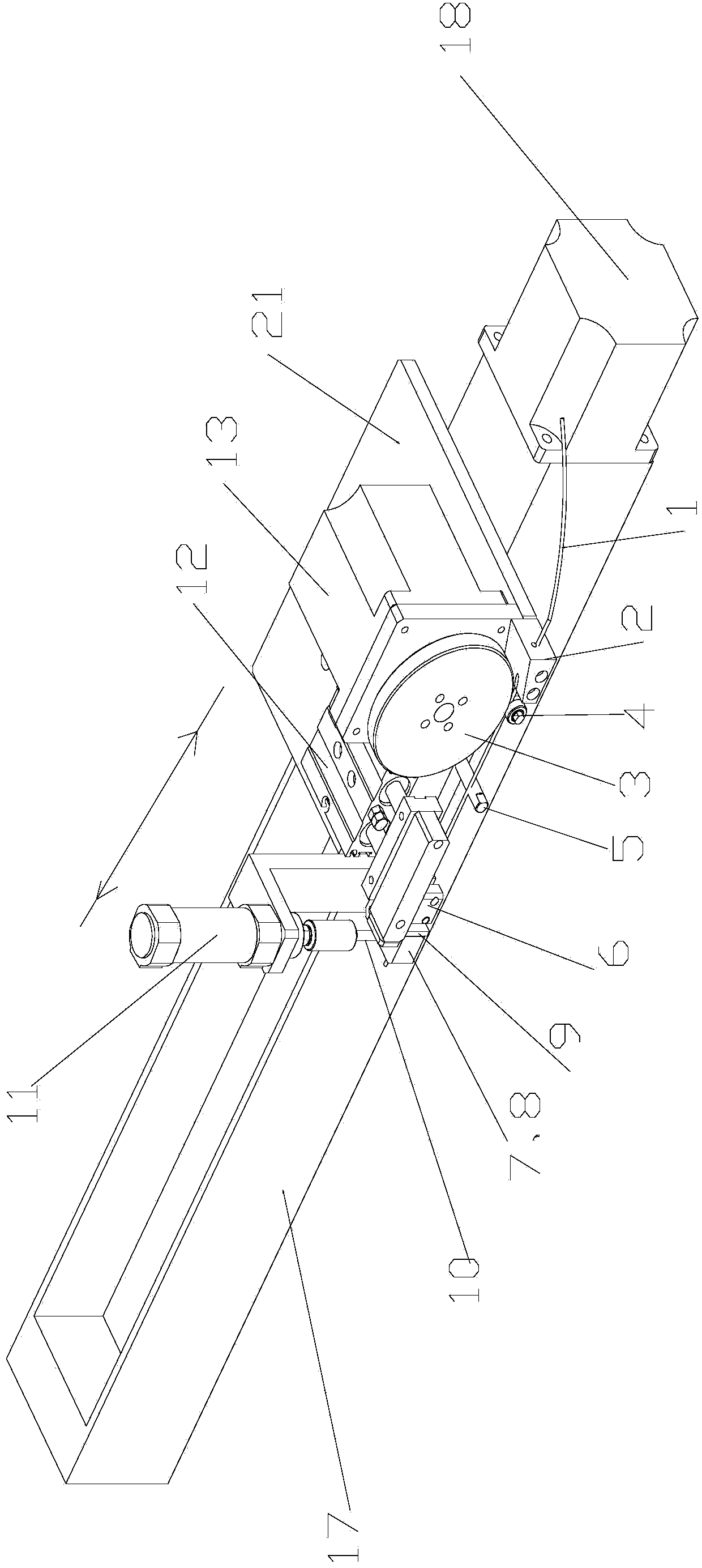

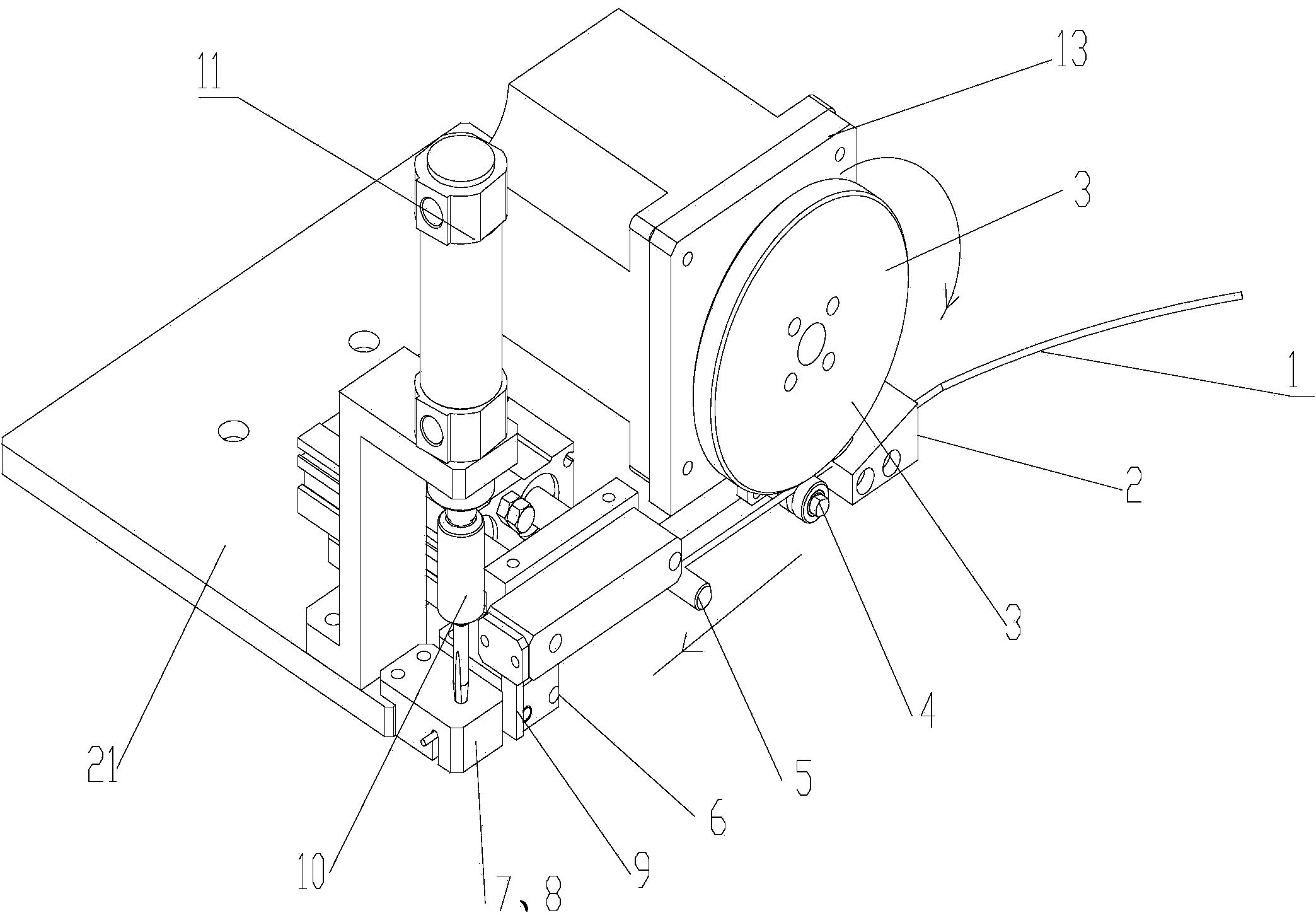

[0040] Embodiment 1: Referring to the accompanying drawings, reflecting a specific structure of the present invention, the automatic insertion device of the combined fireworks includes a lead wire channel for positioning and conveying the lead wire 1, and the lead wire channel includes constraining elements A2 and Constraint element B8 also includes constraint element C7, constraint element D6 and constraint element E5 (two) located between the two ends, wherein constraint element A2, constraint element B8, constraint element C7, and constraint element D6 all have leads that can The inner twitching hole (such as a tubular lumen); the constraining element E5 is a support rod for supporting the lead wire 1 . The gap between the constraint element B8 and the constraint element C7 corresponds to the insertion position of the insertion rod 10, and the gap between the constraint element C7 and the constraint element D6 corresponds to the cutting position of the cutter 9, which is con...

Embodiment 2

[0047] Embodiment 2: The difference with Embodiment 1 is that in the automatic insertion device, the mechanism that causes the relative displacement between the insertion mechanism and the tray selects the A scheme, and its specific structure can be found in Figure 12 : the feed tray 16 is provided with a displacement drive mechanism to drive the feed tray 16 linear reciprocating translation; the displacement drive mechanism includes a moving drive stepper motor 101, a screw guide rail 102, and the feed tray 16 is installed on the screw guide rail 102, and the displacement Drive the stepper motor 101 to connect the tray 16 and drive the tray 16 to translate along the screw guide rail 102 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com