Large profile automatic measurement assisting device based on laser tracker

A laser tracker and measuring device technology, which is applied to measuring devices, optical devices, instruments, etc., can solve the problems of complex motion control of lifting mechanisms, large measuring workload, low target positioning accuracy, etc., to achieve automatic measurement, guarantee The effect of measurement accuracy and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features and functions realized by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

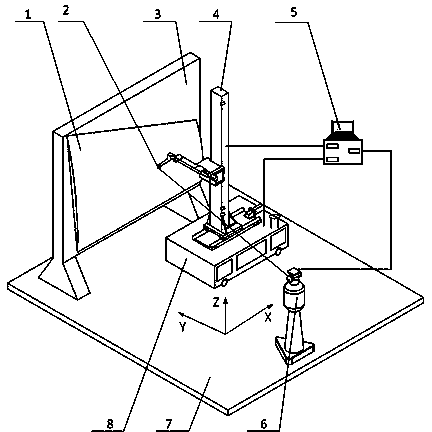

[0025] Such as figure 1 Shown is the overall system layout of the present invention, the measurement system is mainly composed of a computer control system 5 , a rectangular three-coordinate servo mechanism 4 , a navigation car 8 and a laser tracker 6 . Wherein, the rectangular three-coordinate servo mechanism 4 is installed on the navigation car 8 , and the target 2 is clamped on the rectangular three-coordinate servo mechanism 4 . The computer control system 5 is mainly used for data communication with the rectangular three-coordinate servo mechanism and the laser tracker, and for extracting data information of the product to be tested. Through the extracted data, the rectangular three-coordinate servo mechanism is controlled to move to the corres...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap