Capacitance type moisture condensation sensor

A sensor, capacitive technology, applied in the field of sensors, can solve the problems of changes in the characteristics of induction, time-consuming and laborious, and large deviation of monitoring results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

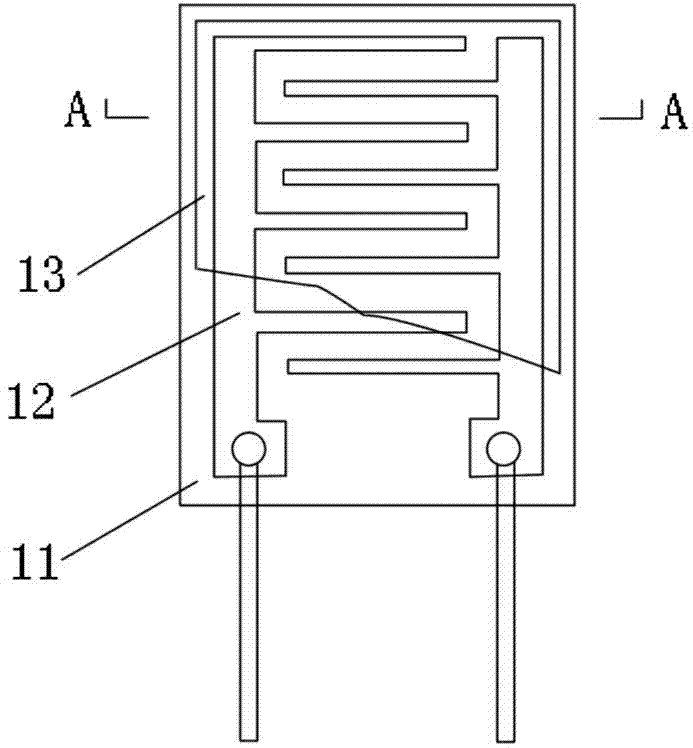

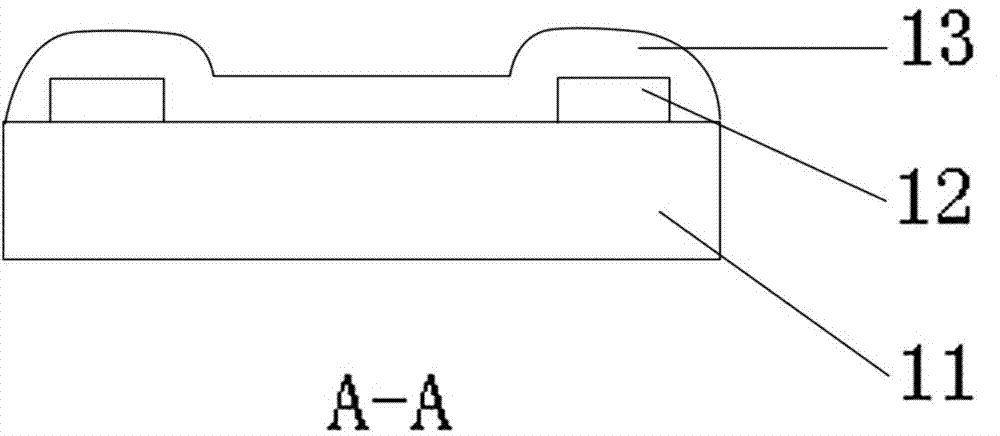

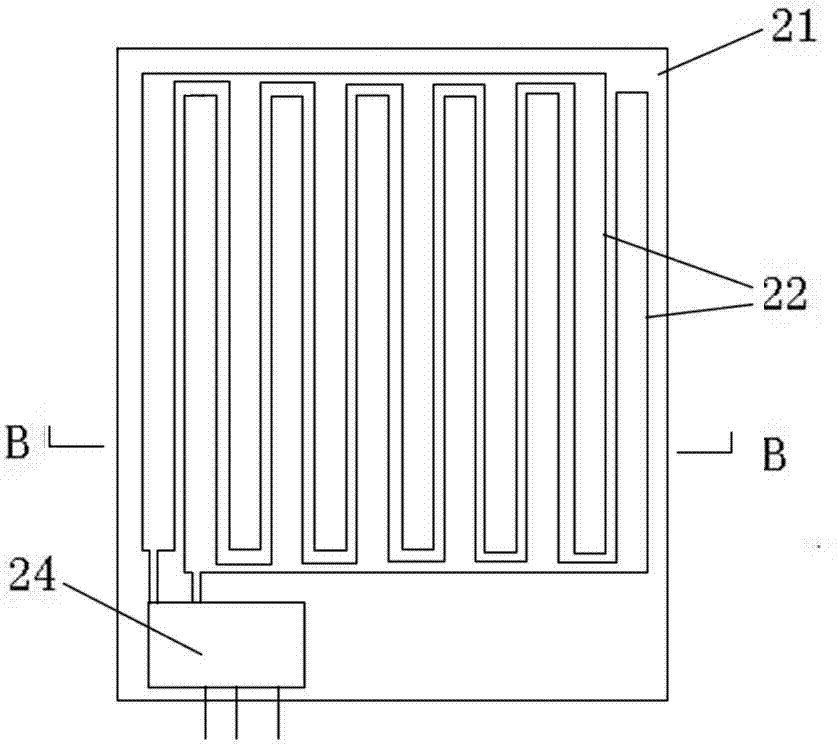

[0024] image 3 A schematic structural diagram of a capacitive dew sensor provided in an embodiment of the present invention, Figure 4 for image 3 Schematic diagram of the structure of the B-B section in the middle, combined with image 3 and Figure 4 As shown, the capacitive dew sensor includes a substrate 21, and a capacitor grid 22 arranged on the substrate 21, the surface of the capacitor grid 22 is also provided with an insulating layer 23; the capacitor grid 22 includes two sets of comb-shaped capacitor plates, two sets of comb-shaped The capacitor plates are distributed across.

[0025] The highly reliable capacitive dew sensor provided in this embodiment has two sets of comb-shaped metal capacitance grids cross-distributed on the substrate. The capacitor grid is covered with an insulating layer, that is to say, the capacitor grid is sealed ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com