Fault monitoring method for high-voltage cable

A technology for fault monitoring and high-voltage cables, which is applied in the direction of fault location, measuring electricity, and measuring devices, to achieve accurate fault judgment, simple device structure, and practical and feasible methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

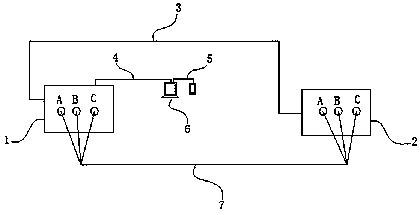

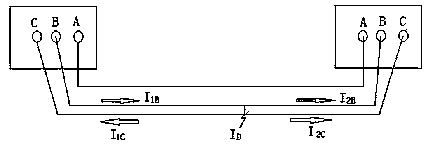

[0023] Install the cable current measuring device, temperature measuring device and remote terminal device of the present invention at the first and last ends of the cable respectively, monitor the cable grounding, short circuit, and disconnection on-line, and compare and judge by using the operating conditions of the current measuring devices on both sides of the cable Fault category.

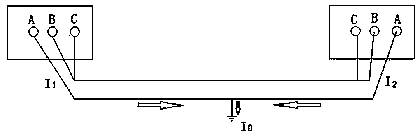

[0024] single-phase-to-earth faults, such as figure 2 shown. When a single-phase-to-earth fault (such as phase A) occurs, three situations may occur:

[0025] (1) A current I appears at the head end of the cable 1 Sudden increase, the cable end current I 2 constant;

[0026] (2) Current I appears at the head end of the cable 1 Sudden increase, the cable end current I 2 is zero;

[0027] (3) Cable head end I 1 is zero, the terminal current I 2 A reverse increase occurs.

[0028] The above three situations can be judged by monitoring the current change or temperature change at the beg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com