On-line Monitoring System and Method for Thermal Defects of High Voltage Switchgear

A high-voltage switchgear and monitoring system technology, applied in the direction of measuring electricity, measuring devices, measuring heat, etc., can solve the problems of excessive changes to the original equipment of the switchgear, difficult and incomplete operation and maintenance of the switchgear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

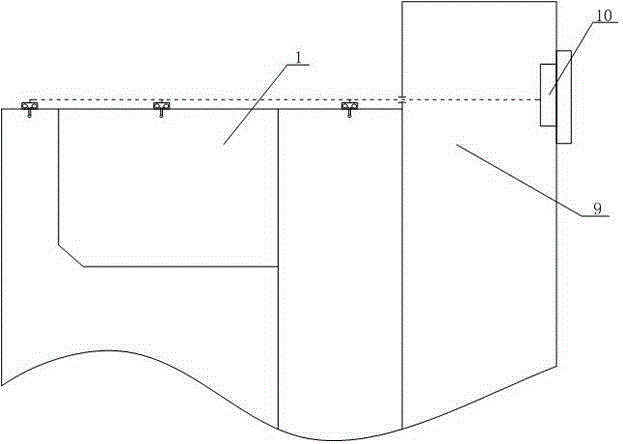

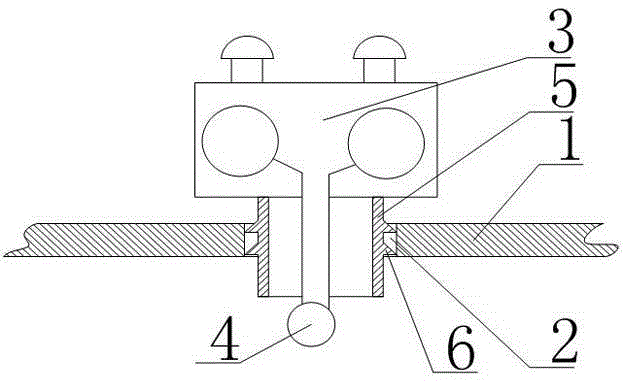

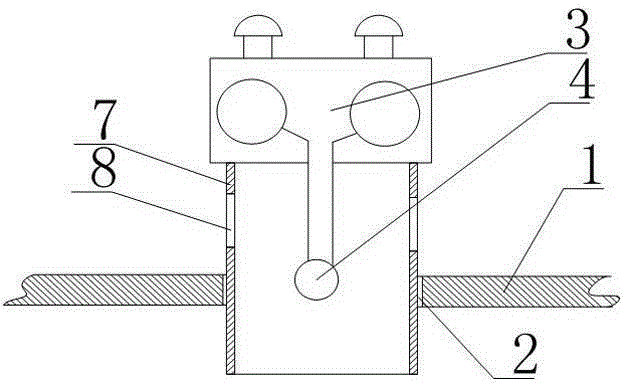

[0072] Such as Figures 1 to 2 As shown, the high-voltage switchgear thermal defect online monitoring system of the present invention is composed of sensors and a data receiving unit 10 as a data processing system. The sensors include 2 to 5 temperature sensors and a current sensor, and one of the temperature sensors is installed on the high-voltage switch The outside of the cabinet is used to detect the ambient temperature, and the rest of the temperature sensors are installed in the top space of the current-carrying compartment of the high-voltage cabinet to detect the air temperature in the compartment, and the current sensor is installed in the secondary wiring of the current transformer in the secondary room of the high-voltage switchgear Above; the high-voltage switchgear body 1 has three current-carrying compartments, and different types of high-voltage switchgear bodies 1 may also have different numbers of current-carrying compartments, which are set on the top of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com