Light-emitting diode (LED) display screen and packaging method thereof

A technology of LED display screen and packaging method, which is applied in the direction of identification devices, instruments, electrical components, etc. It can solve problems such as short circuit, easy convergence of light-emitting areas, affecting product yield and production capacity, etc., to achieve clear display effect and reduce mixed light phenomenon or the effect of infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

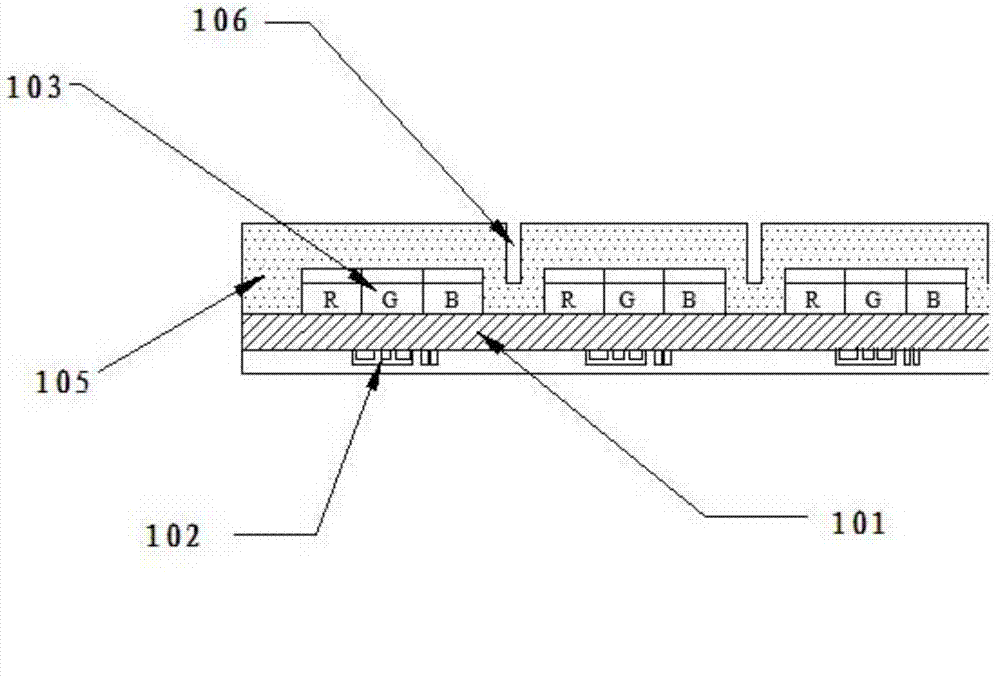

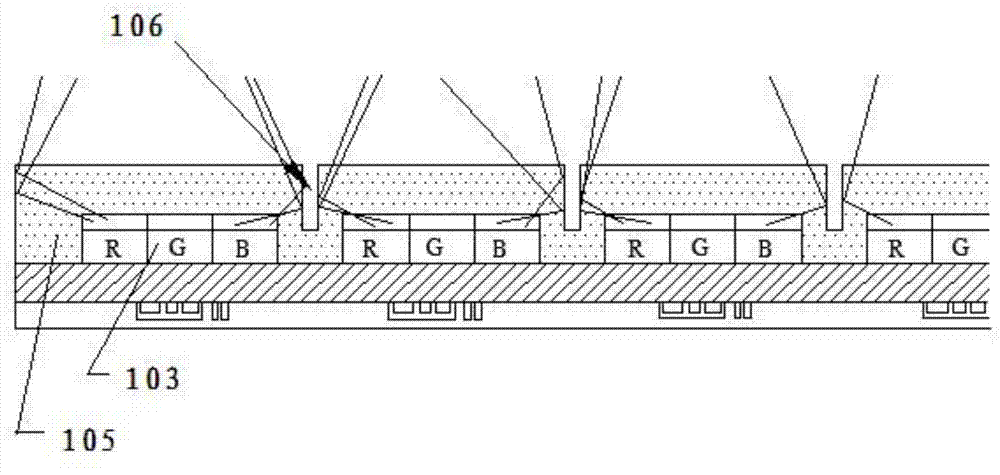

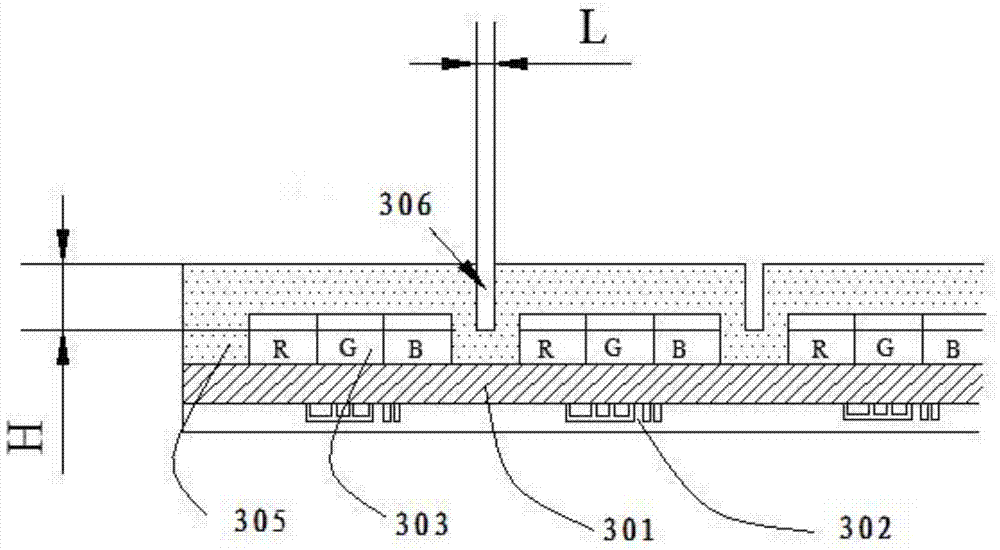

[0048] The embodiment of the present invention provides an LED display screen, which can further reduce the distance between each group of RGB LED chips, improve the resolution of the display screen, and effectively solve the problem of confusion between RGB LED chips. Light phenomenon, thereby effectively improving the display effect.

[0049] Combine the following figure 1 The specific structure of an LED display screen provided by the embodiment of the present invention is described in detail;

[0050] Such as figure 1 As shown, the LED display screen specifically includes a COB board 101, at least one driver chip 102 and an LED lamp module.

[0051] Its specific structure is that the driver chip 102 is arranged on the back of the COB board 101 , and the LED lamp module is arranged on the front of the COB board 101 .

[0052]Specifically, the LED lamp module includes at least one set of RGB LED chips 103, and the set of RGB LED chips 103 is arranged in a straight line; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com