Electroluminescent component and packaging method thereof

An electroluminescence element and electroluminescence technology are applied in the fields of organic light-emitting devices, organic light-emitting device manufacturing/processing, electrical components, etc., which can solve problems such as poor packaging, inability to completely cover areas, and difficulty in accurately controlling filling volume, etc., to achieve The effect of preventing air bubbles and precisely controlling the thickness of the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

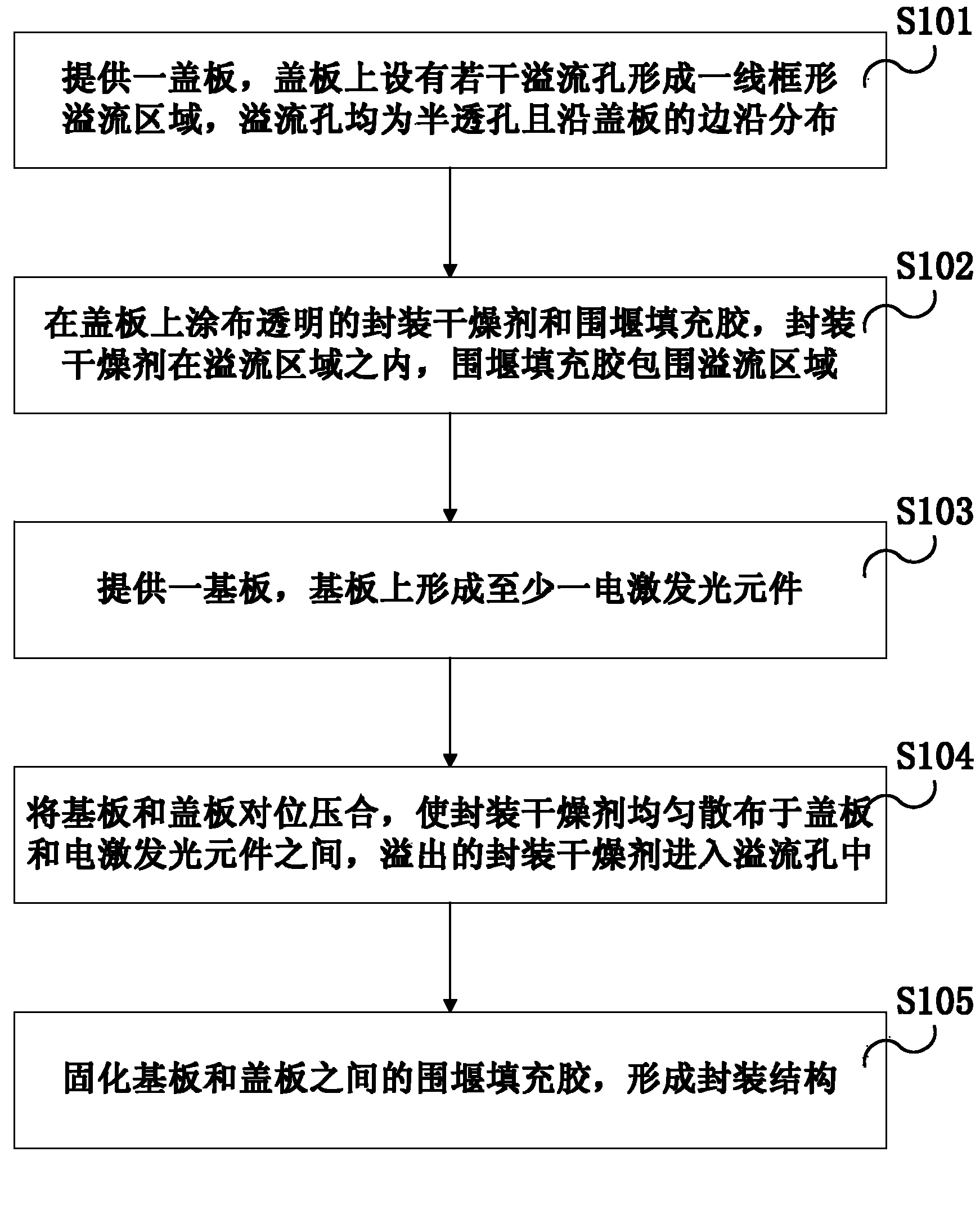

[0063] figure 1 A flow chart showing the packaging method of the electroluminescence component of the present invention according to the first embodiment of the present invention. Such as figure 1 As shown, the packaging method of the electroluminescence component of the present invention comprises the following steps:

[0064]Step S101 : providing a cover plate, on which a number of overflow holes are provided to form a line-frame overflow area, and the overflow holes are all semi-permeable holes and distributed along the edge of the cover plate.

[0065] Step S102: Coating transparent encapsulation desiccant and cofferdam filling glue on the cover plate, the encapsulation desiccant is inside the overflow area, and the cofferdam filling glue surrounds the overflow area.

[0066] Step S103: providing a substrate on which at least one electroluminescence element is formed.

[0067] Step S104: Align and press the base plate and the cover plate, so that the encapsulation desic...

no. 2 example

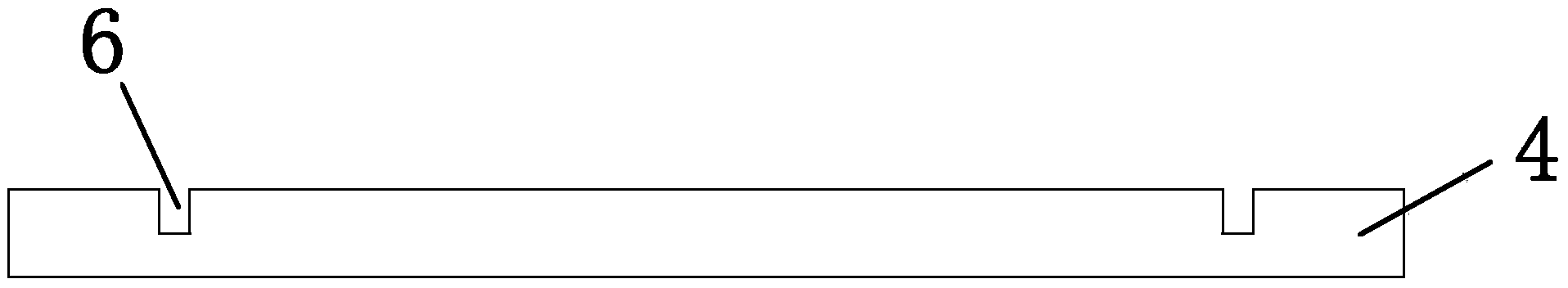

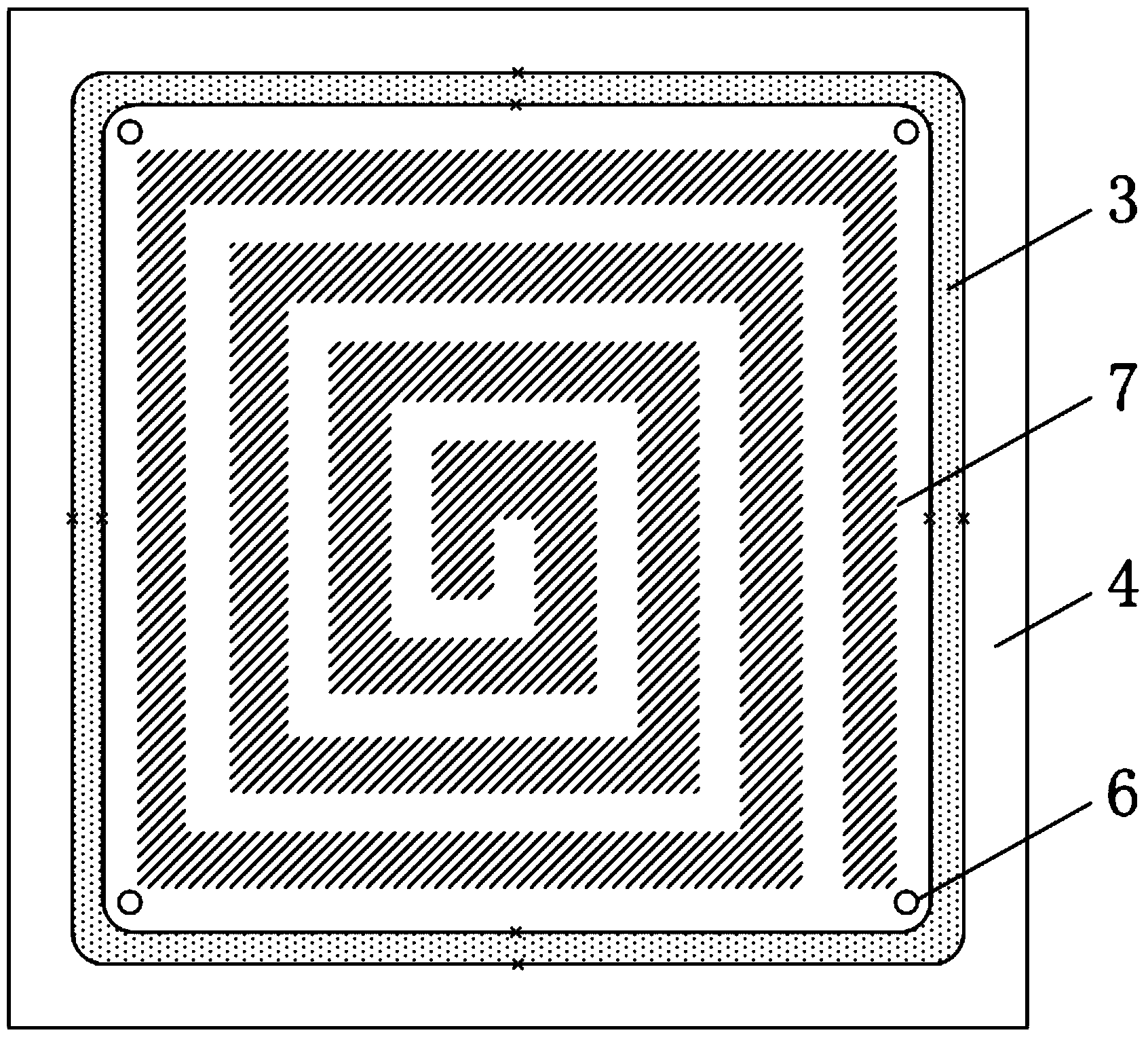

[0081] Figure 9 A cross-sectional view of the electroluminescence component in the present invention is shown according to the second embodiment of the present invention. Such as Figure 9 As shown, the present invention also provides an electroluminescent component, which is made by the packaging method of the above electroluminescent component, and includes a cover plate 4 and a substrate 1, the substrate 1 is provided with an electroluminescent element 5, and the cover plate 4 is provided with an electroluminescent element 5. A number of overflow holes 6 form a line-frame-shaped overflow area. The overflow holes 6 are all semi-permeable holes and are distributed along the edge of the cover plate 4. The cover plate 4 is coated with transparent packaging desiccant 7 and cofferdam filling glue 3 , the packaging desiccant 7 is within the overflow area, and the cofferdam filling glue 3 surrounds the overflow area. The base plate 1 and the cover plate 4 are cured and encapsula...

no. 3 example

[0085] Figure 10 A top view of the cover plate in the present invention is shown according to the third embodiment of the present invention. Such as Figure 10 As shown, a cover plate is provided, the area on the cover plate 4 that does not need to be etched is protected with photoresist, and then 16 overflow holes 6 are etched along a square frame by hydrofluoric acid. Wherein, the diameter of each overflow hole 6 is 0.8 mm, which can prevent the cover plate 4 from being deformed or broken due to the excessively large diameter of the overflow hole 6, and at the same time ensure a certain accommodation space. The shape of the overflow hole can be any one of circle, ellipse, rectangle, triangle, rhombus and crescent. The depth of the overflow hole 6 is 40% of the thickness of the cover plate 4 . The residual hydrofluoric acid on the cover plate 4 is washed away with deionized water, so as to prevent the influence of the residual hydrofluoric acid on subsequent process steps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com