Temporary supporting rod for high-voltage line

A technology for temporary support and high-voltage wires, which is applied in the direction of overhead lines/cable equipment, etc., and can solve problems such as wire tension and power supply safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

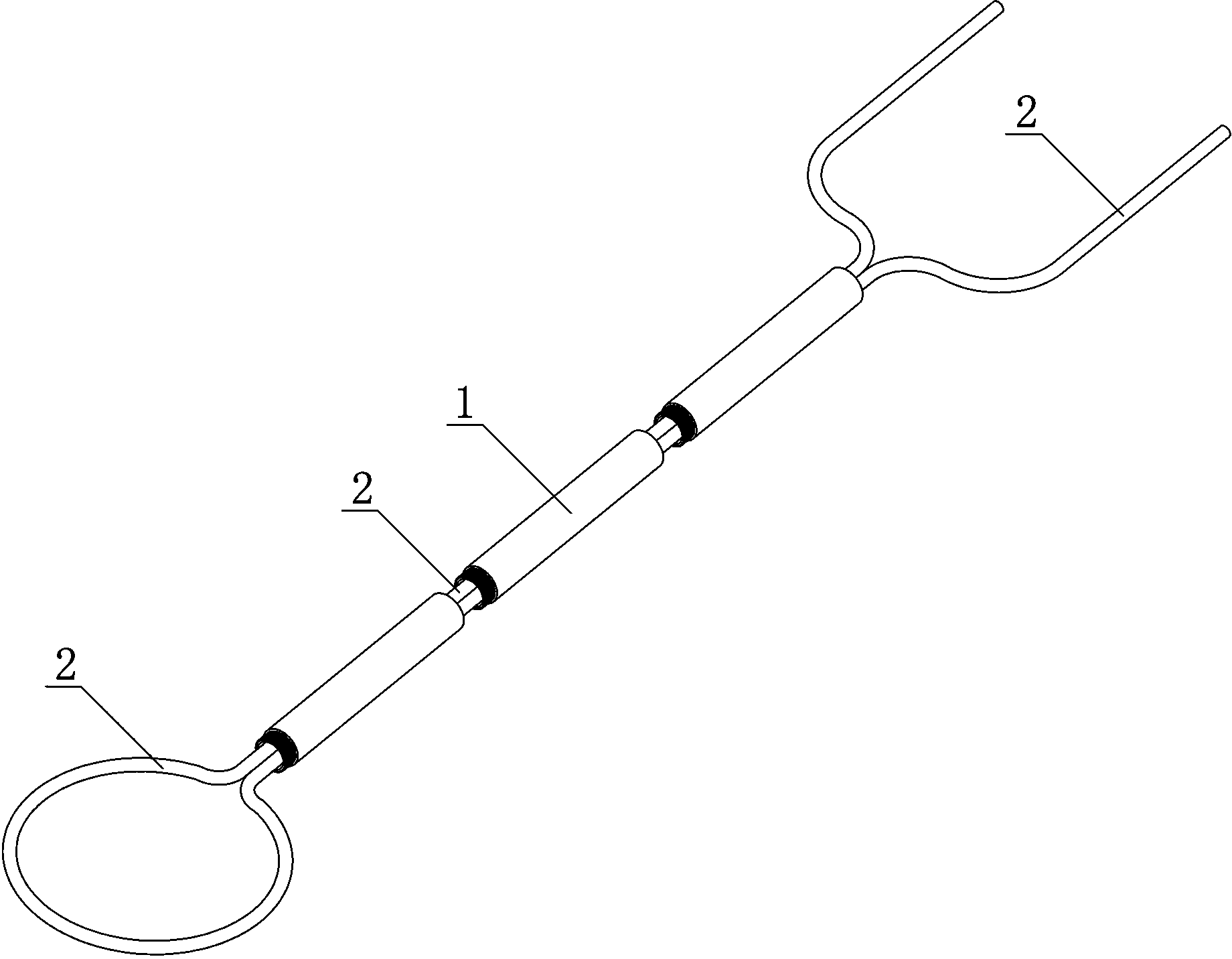

Embodiment 1

[0021] Such as figure 1 As shown, a temporary support rod for high-voltage electric wires includes an insulating support tube 1 and a fastening rope 2 , and the fastening rope 2 is folded in half and passed through the insulating support tube 1 . When in use, pass the fastening rope 2 around the high-voltage electric wire and pull up the high-voltage electric wire, then insert both ends of the fastening rope 2 into one end of the insulating support tube 1 at the same time, and pull it up from the insulating support tube 1. The other end stretches out, and then the two free ends of described fastening rope 2 are walked around tree branch and tied up, and described high-voltage electric wire is hoisted. If only the high-voltage wire is pulled up with the fastening rope 2, it will still shake a lot when the wind blows, so the function of the insulating support tube 1 is to control the distance between the high-voltage wire and the tree branches, so as to Reduce the swaying range...

Embodiment 2

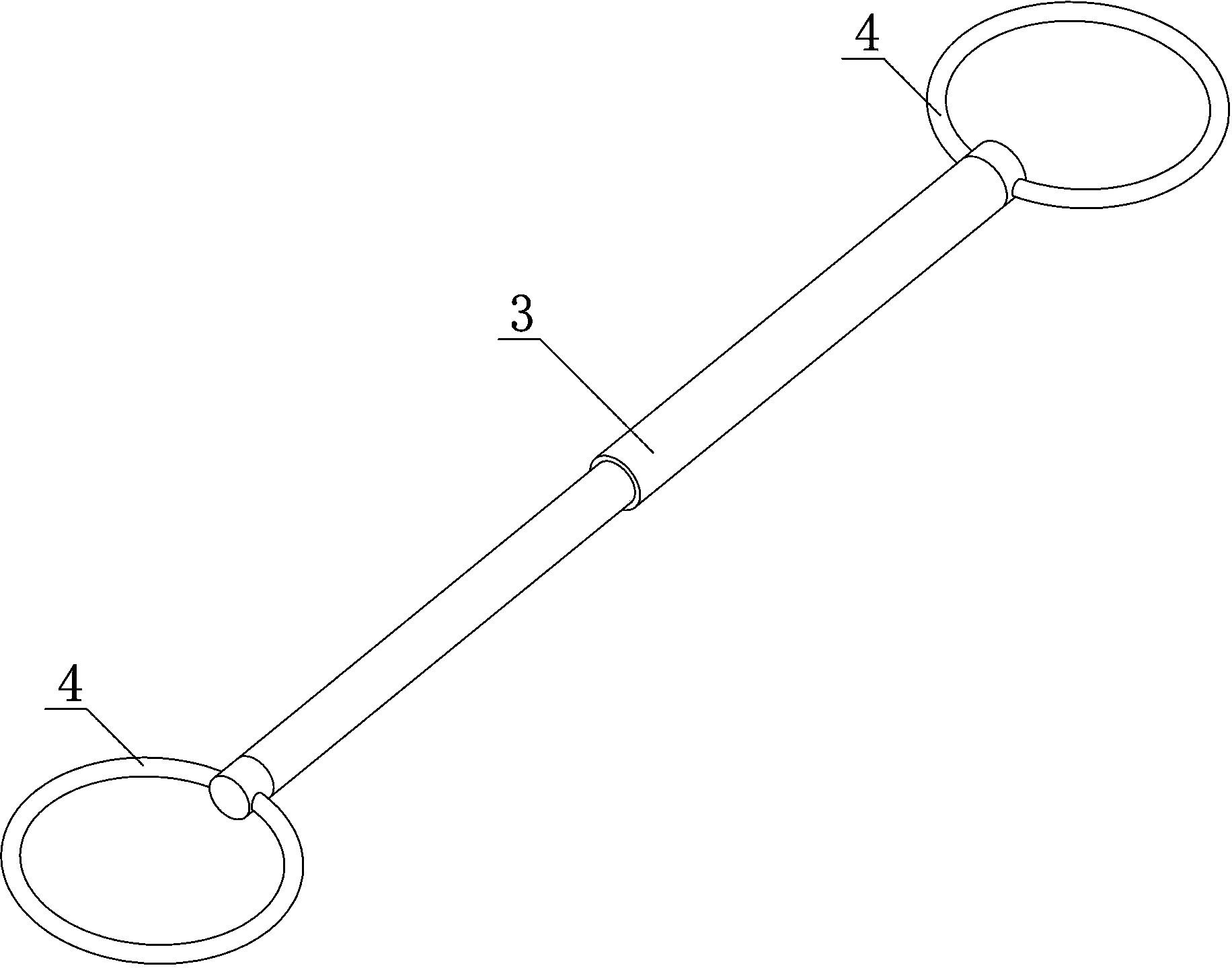

[0024] Such as figure 2 As shown, the difference between Embodiment 2 and Embodiment 1 is: a temporary support rod for high-voltage electric wires, including an insulating support rod 3 and an insulating fixing ring 4 that is rotatably connected to both ends of the insulating supporting rod 3, and the insulating fixing ring 4 The ring 4 is provided with movable openings. When in use, pass the drooping high-voltage wire through the movable opening into one of the insulating fixing rings 4, then pull up the high-voltage wire and hang the other insulating fixing ring 4 on the tree branch through the movable opening superior.

[0025] The movable opening can be a commonly used structure such as an elastic buckle. The purpose of rotating the insulating fixing ring 4 and the insulating support rod 3 is to adapt to the extending direction of the high-voltage electric wire and the extending direction of the branches of trees.

[0026] The insulating support rod 3 is a telescopic r...

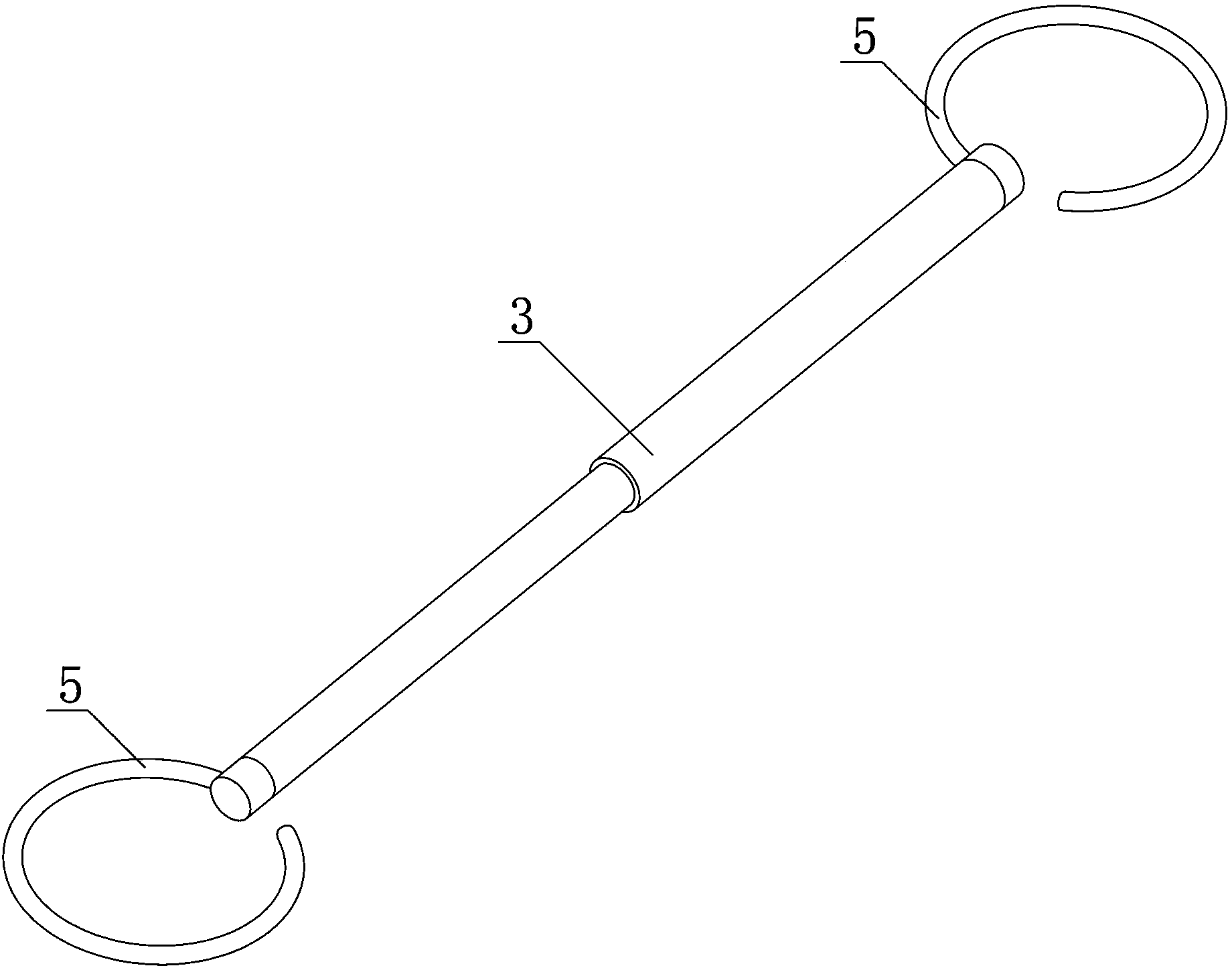

Embodiment 3

[0028] Such as image 3 As shown, the difference between embodiment 3 and embodiment 2 is: a temporary support rod for high-voltage electric wires, including an insulating support rod 3 and insulating hooks 5 respectively connected to both ends of the insulating support rod 3 in rotation. In this way, the insulating hook 5 is designed to replace the insulating fixing ring 4, so that the working process of hoisting high-voltage electric wires is more concise, and it can be hung up once.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com