Lighting bus duct connector

A technology of busway connectors and connecting grooves, which is applied in the direction of fully enclosed busway devices, can solve the problems of short circuit explosion of busway joints, achieve the effect of simple structure and ensure normal power supply and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing.

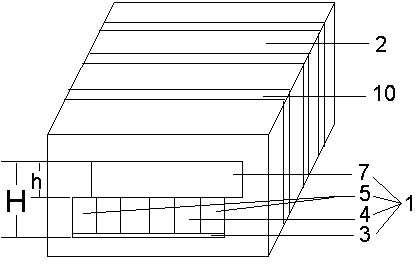

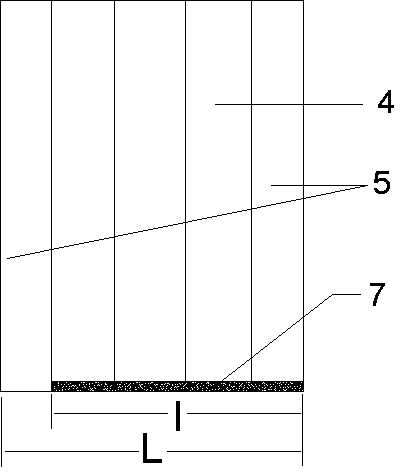

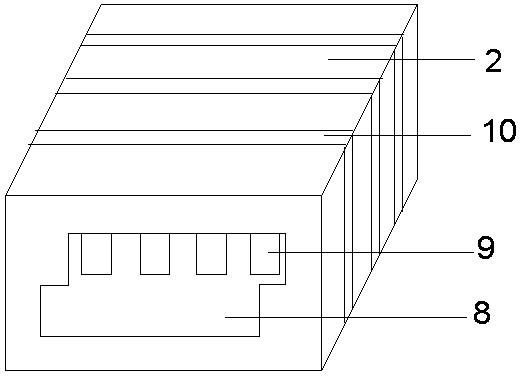

[0012] As shown in the figure, a lighting busway connector includes a conductive mounting base 1 and a closed mounting box 2, wherein the outer surface of the closed mounting box 2 is provided with a guide groove 10 in the circumferential direction, and the conductive mounting base 1 includes a base 3 , the base 3 is provided with a connection groove 4, a sealing groove 5 is provided on both sides of the connection groove 4, a baffle 7 is provided on the upper side of the connection port of the connection groove, and the baffle 7 The height h is smaller than the height H of the connecting groove 4, and its width l is smaller than the width L of the base 3, so that the section of the conductive mounting seat 1 is in a "Z" shape, and the closed mounting box 2 is provided with a cavity 8 , the cross-sectional shape of the cavity 8 matches the cross-sectional shape of the condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com