Stator with concentric type winding

A concentric winding and stator technology, applied in the field of stators, can solve the problems of increased cost, high end loss, and high voltage failure rate, so as to improve life and reliability, increase slot area utilization rate, and reduce end loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

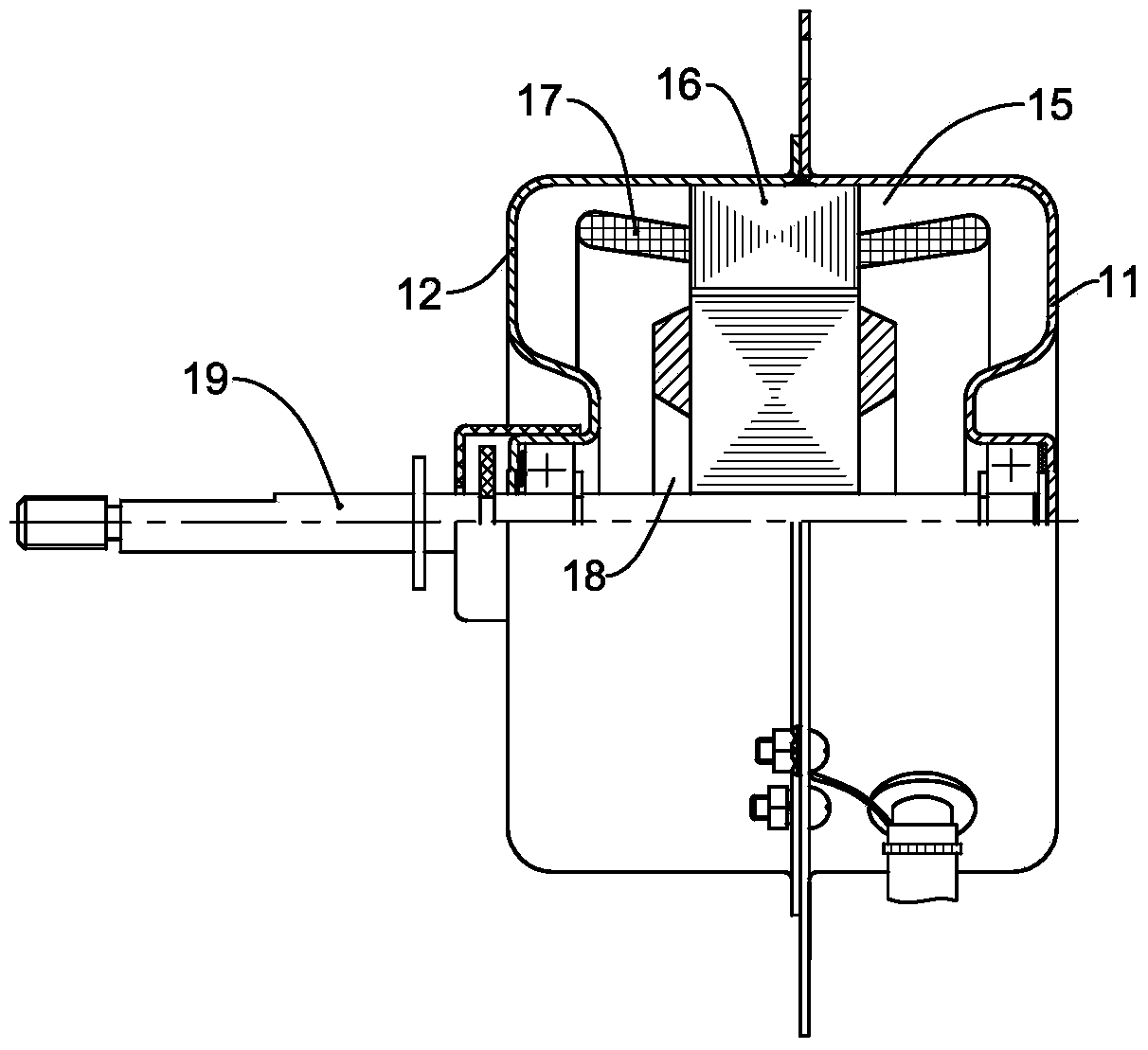

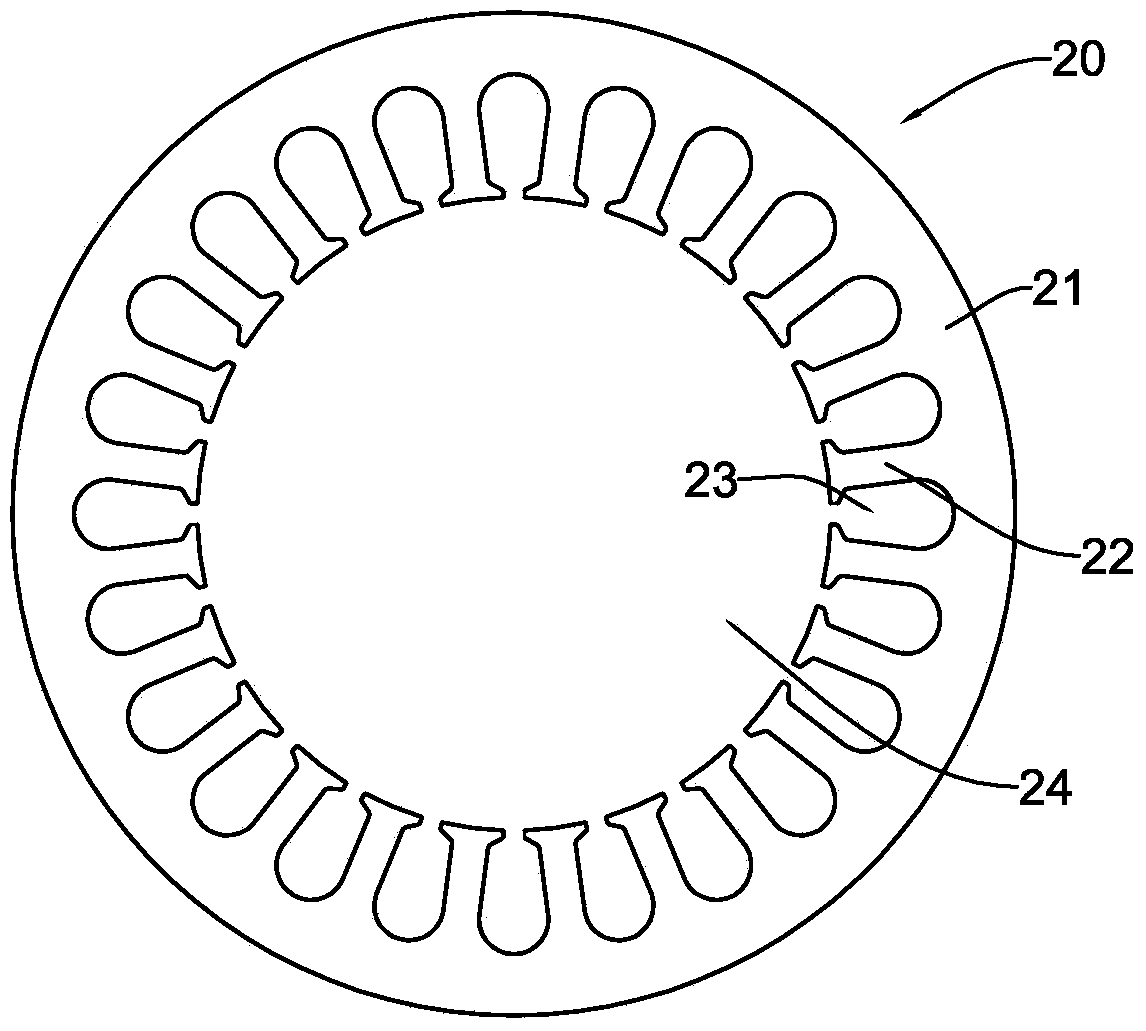

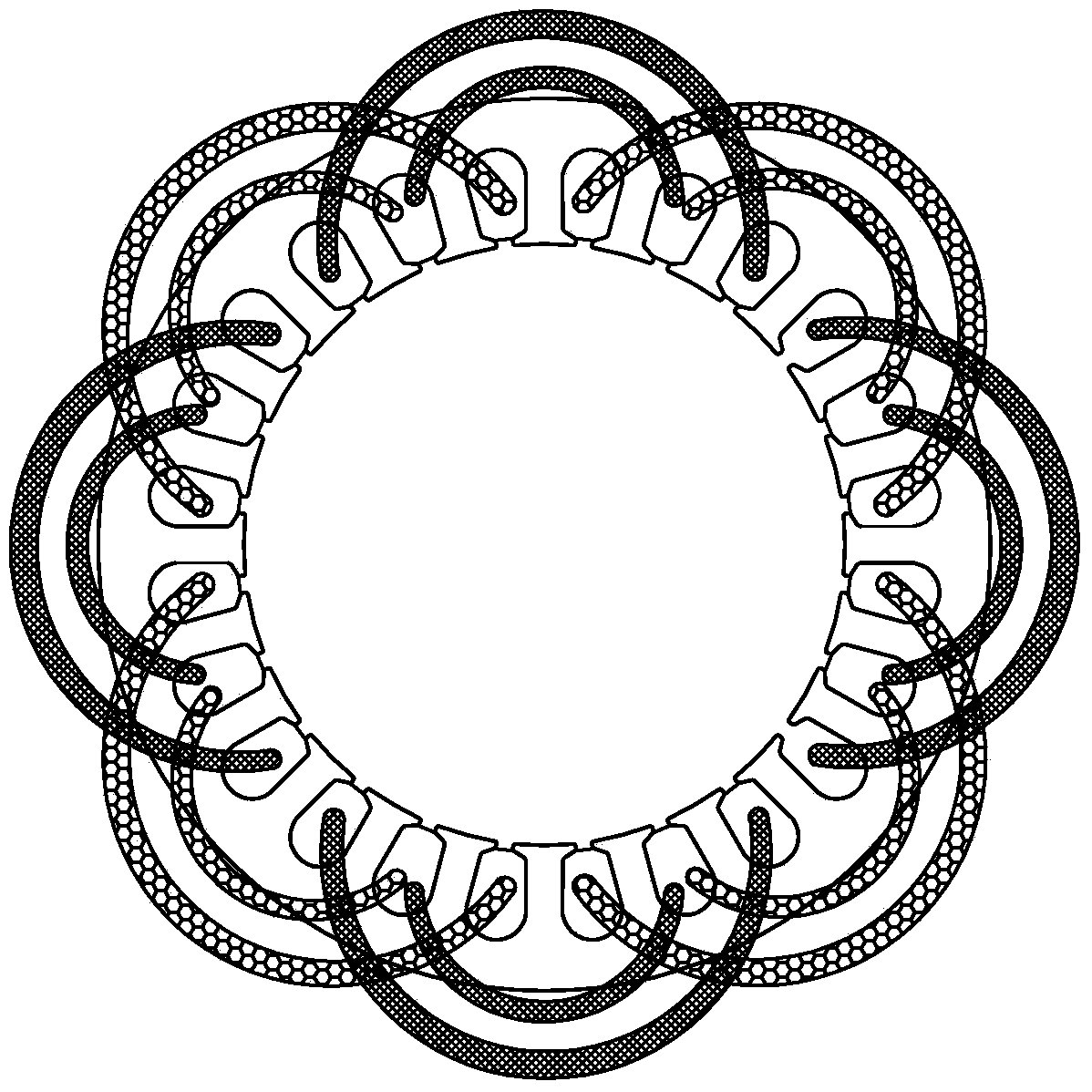

[0020] like Figure 4 As shown, an embodiment of the present invention is a 4-pole 24-slot concentric winding stator, including a stator core 60, an outer coil winding 41 and an inner coil winding 42, wherein the stator core 60 is a yoke separated stator core, It consists of a detachably connected tooth portion 47 and a yoke portion 45 , the annular yoke portion 45 is located on the outer periphery of the tooth portion 47 , and the tooth portion 47 is located inside the yoke portion 45 . A circular hole 43 is provided in the middle of the tooth portion 47 , and the rotor can be installed in the circular hole 43 . The tooth portion 47 can be covered with an insulating sleeve or an injection molded insulating sleeve to prevent the coil winding from contacting the tooth portion 47 . When manufacturing the stator, the coil winding can be directly wound on the tooth part 47 by winding equipment, and then the tooth part 47 wound with the coil winding can be installed in the yoke pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com