Three-phase asynchronous vibration motor

A vibration motor, three-phase asynchronous technology, applied in asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of poor magnetic properties of forming motors, unstable excitation force, low production efficiency, etc. Compact structure and weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings and in combination with specific embodiments, so that those skilled in the art can implement it according to the description. The protection scope of the present invention is not limited to the specific embodiments of the present invention.

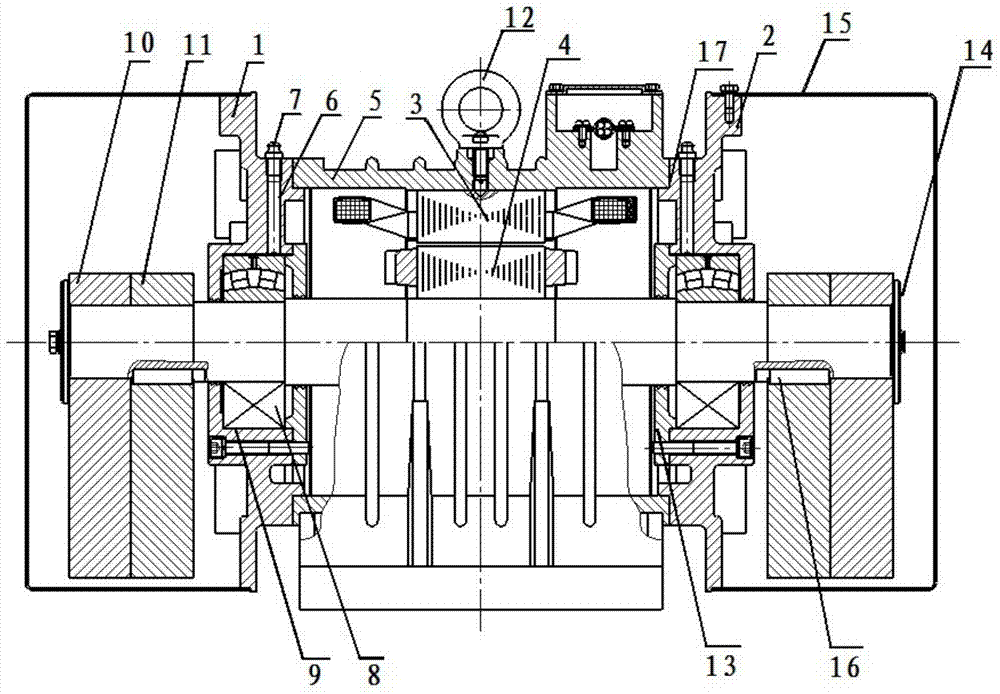

[0020] Such as figure 1 As shown, a three-phase asynchronous vibration motor includes: left end cover 1, right end cover 2, machine base 5, oil nozzle 7, stator 3, rotor 4, spherical roller bearing 8, fixed eccentric block 11, movable eccentric block 10 , the left end cover 1 and the right end cover 2 are engaged on both sides of the machine base 5 by the tooth openings 17 on the left end cover 1 and the right end cover 2 respectively, and the meshing parts of the left end cover 1 and the right end cover 2 and the machine base 5 are fixedly connected by bolts, and the left end The cover 1 and the right end cover 2 each have an oil chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com