Modular rapidly-formed water-cooling plate

A water-cooled plate, modular technology, applied in the direction of cooling/ventilation/heating transformation, can solve the problems of high welding cost and water-cooled plate leakage, avoid high costs, increase thermal performance, and adjust the effect of flow channel layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

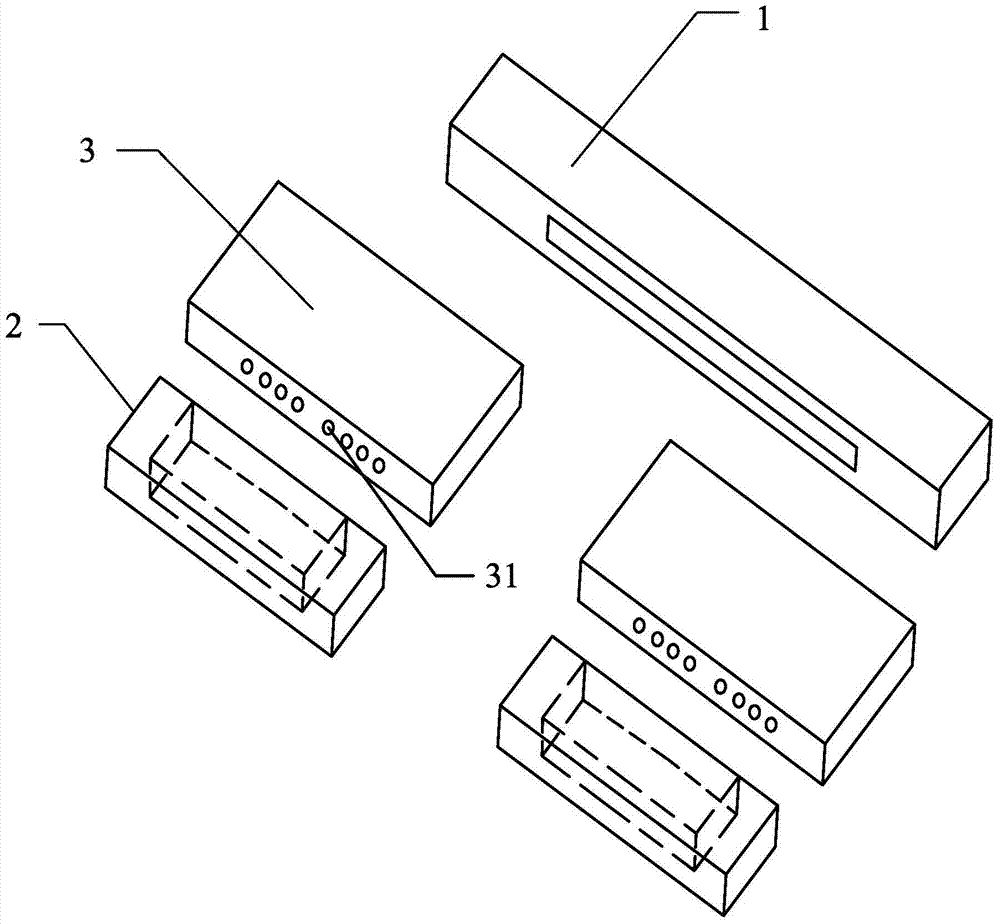

[0022] like figure 1 As shown, a modular rapid prototyping water-cooled plate, according to the given coolant flow rate and the heat generated by electronic power components, after analyzing the thermal resistance, flow resistance and installation space of the water-cooled plate, the main collecting chamber 1 and two main collecting chambers are used. The heat dissipation structure of the cavity 3 and the two collecting chambers 2 matched with the main cavity 3 .

[0023] The main cavity 3 is formed by drawing aluminum, and then the main cavity 3 is processed to the target size. The main cavity 3 is provided with a plurality of flow channels 31 that run through the main cavity 3 and are used for the flow of cooling liquid. The flow channels 31 can be made into at least one of circular, triangular or rectangular cross-sections as required. At least one or more of the flow channels with fins in the flow channel, the inner spiral flow channel with increased longitudinal vortex, ...

Embodiment 2

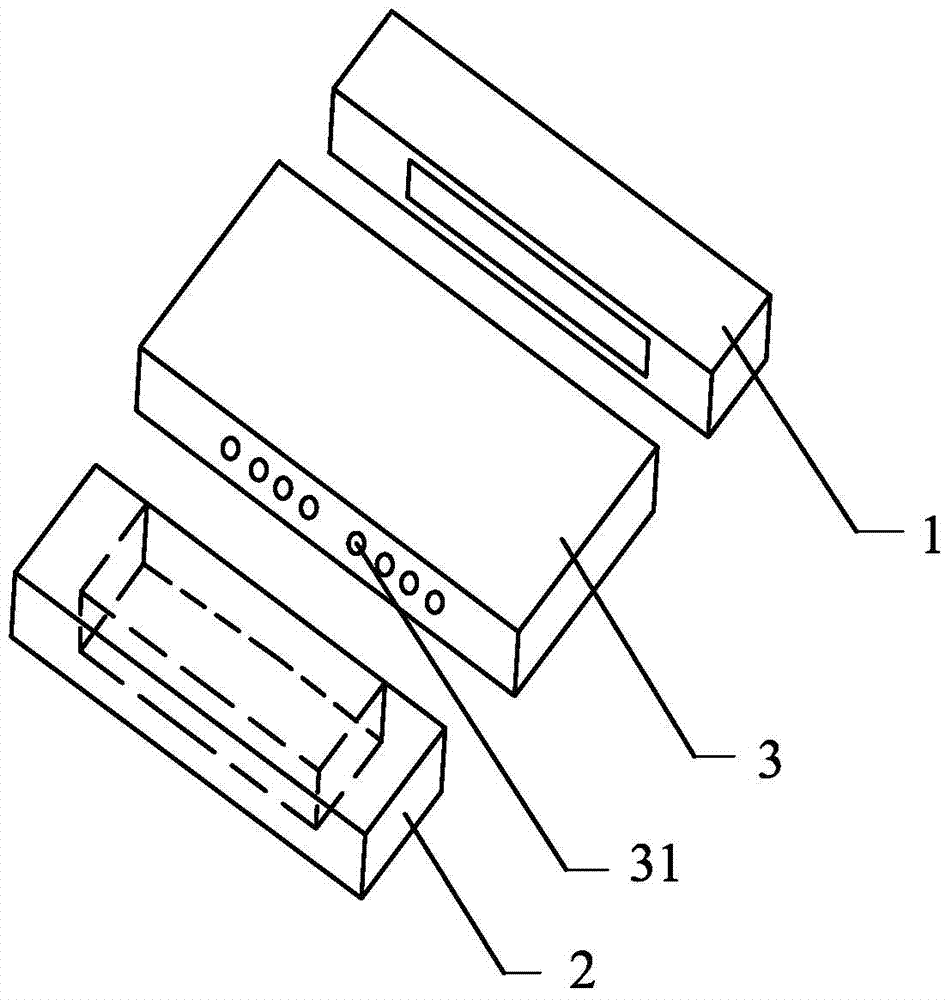

[0026] like figure 2 As shown, a modular rapid prototyping water-cooled plate, according to the given coolant flow rate and the heat generated by electronic power components, after analyzing the thermal resistance, flow resistance and installation space of the water-cooled plate, the main collecting chamber 1 and a main chamber are used Body 3 and a heat dissipation structure form of a collecting chamber 2 matched with the main cavity 3 .

[0027] The main cavity 3 is formed by drawing aluminum, and then the main cavity 3 is processed to the target size. The main cavity 3 is provided with a plurality of flow channels 31 that run through the main cavity 3 and are used for the flow of cooling liquid. The flow channels 31 can be made into at least one of circular, triangular or rectangular cross-sections as required. At least one or more of the flow channels with fins in the flow channel, the inner spiral flow channel with increased longitudinal vortex, or the special-shaped fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com