Multifunctional rotary tillage, fertilization and seeding machine

A seeder and a multi-functional technology, applied in the field of agricultural and forestry machinery, can solve the problems of increasing the number of machines and tools to go to the ground, the adjustment range is small, and the production cost is increased, and the effect of reducing the number of compactions, facilitating crop growth and reducing production costs is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

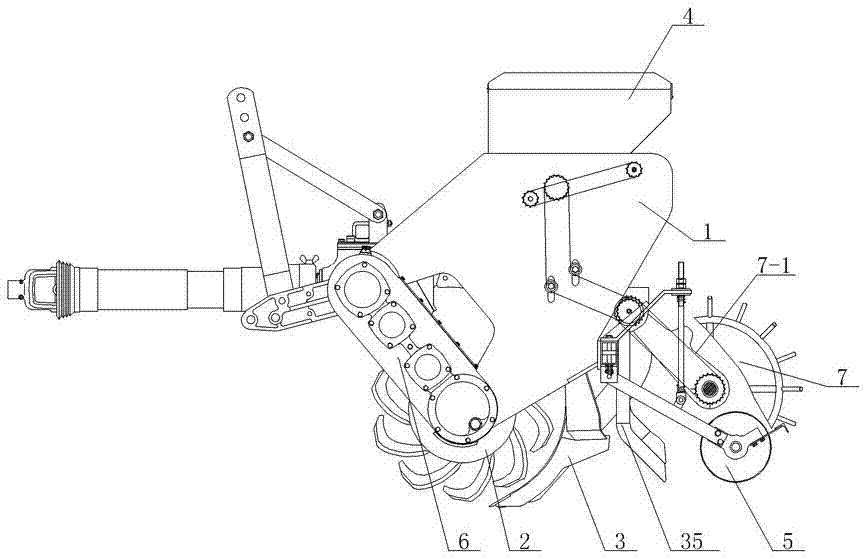

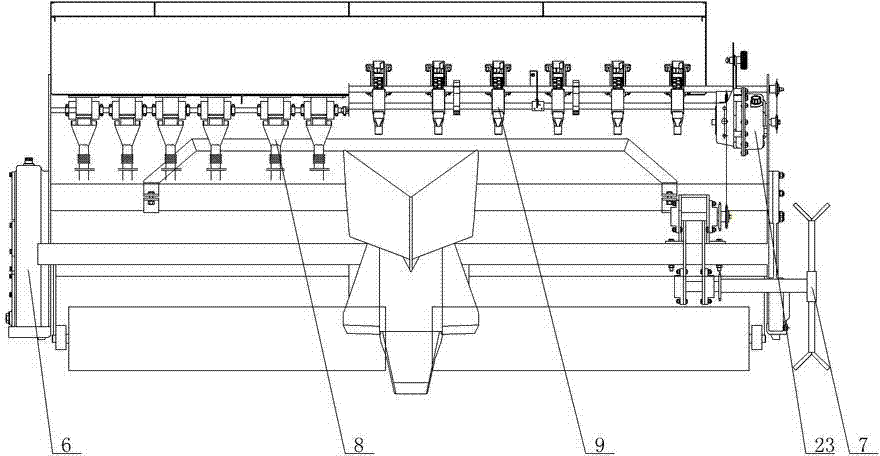

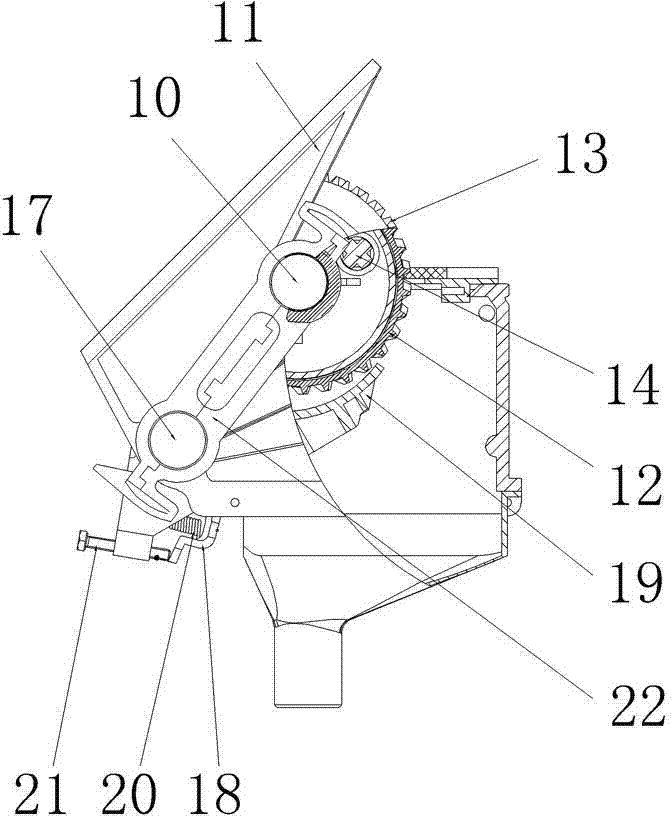

[0024] The multifunctional rotary tillage fertilizing seeder of the present embodiment, as figure 1 and figure 2 shown, including rack 1. The front part of the frame 1 is provided with a rotary tillage ditching mechanism 2 and an auxiliary ditching mechanism 3 , the middle part of the frame 1 is provided with a fertilization and seeding mechanism 4 , and the rear part of the frame 1 is provided with a suppressing soil covering mechanism 5 . One side of the frame 1 is provided with a first transmission 6 connected to an external power output end, and the other side of the frame 1 is provided with ground wheels 7 .

[0025] The fertilization and seeding mechanism 4 includes a fertilizer discharger 8 and a seed metering device 9 . The power output end of the first transmission 6 is connected to the power input end of the rotary tillage ditching mechanism 2, and the ground wheel 7 is respectively connected to the power input ends of the fertilizer discharger 8 and the seed mete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com