Electromagnetic induction heating device for tire vulcanization outer mould

An electromagnetic induction heating and tire vulcanization technology, which is applied in tires, applications, household appliances, etc., can solve the problems of increased manufacturing cost of external molds, easy corrosion of external molds by steam, and impact on service life, so as to save equipment investment, Effect of shortening vulcanization cycle and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

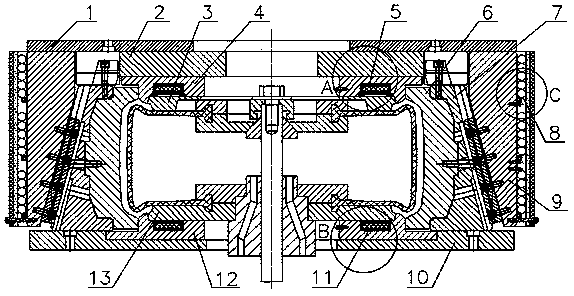

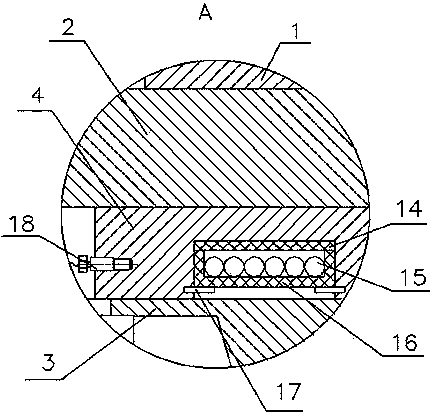

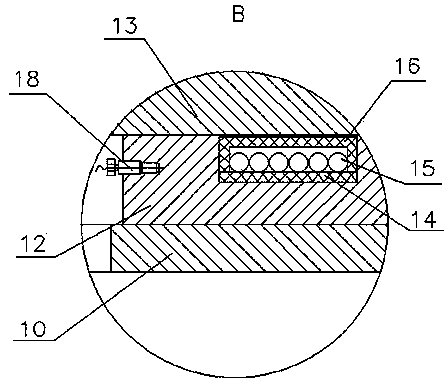

[0016] see Figure 1 to Figure 7 , the present invention is mainly composed of the upper side plate heating unit 5, the lower side plate heating unit 11 and the middle mold cover heating unit 8. Upper side plate heating unit 5 mainly comprises backing plate 14, disk-shaped electromagnetic coil 15, coil cover plate 16, and backing plate 14, coil cover plate 16 are made of heat-insulating material, such as epoxy resin, on upper side plate 4, have The annular groove 24, the backing plate 14 is laid in the annular groove 24, the disc-shaped electromagnetic coil 15 is placed on the backing plate 14, the upper part of the disc-shaped electromagnetic coil 15 is the coil cover plate 16, and the annular ring at the place close to the coil cover plate 16 A certain number of pins 17 are evenly housed on the groove 24 walls. The lower side plate heating unit 11 mainly includes a backing plate 14, a disc-shaped electromagnetic coil 15, and a coil cover plate 16. An annular groove 24 is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com