Novel hot-rolled titanium-aluminum-stainless steel compound plate, production method and application thereof

A stainless steel plate and production method technology, applied in chemical instruments and methods, layered products, metal rolling, etc., can solve the problems of inability to produce composite steel plates with a thickness less than 15mm, and achieve high-strength and high-gloss surface appearance, fast heat dissipation, and sound transmission blunt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

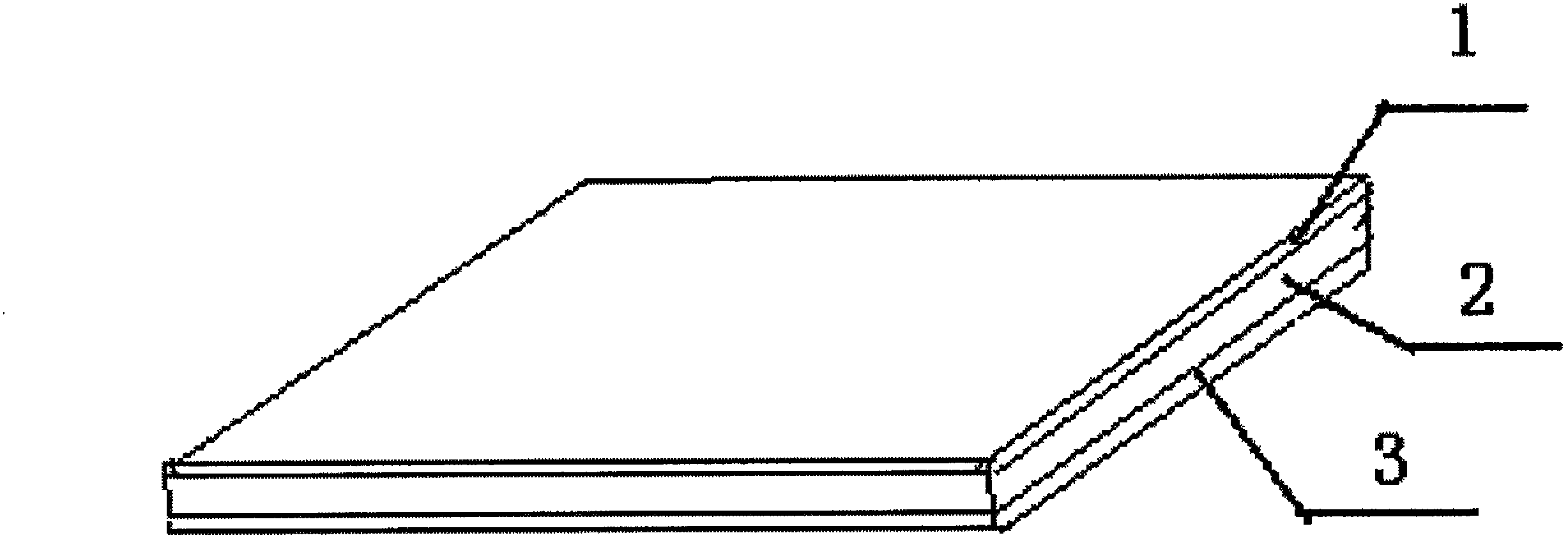

[0035] Example 1: A titanium-aluminum-stainless steel clad plate with a thickness of 3.15 mm as a hot-rolled composite product.

[0036] Among them: imported titanium plate with a thickness of 0.6mm, 1050 pure aluminum plate with a thickness of 3mm, and 304 stainless steel plate with a thickness of 0.9mm.

[0037] ①Titanium plate pre-treatment: place the titanium plate in an annealing furnace of 500-9000 for annealing treatment, the time is 25-50 minutes, take it out and cool it naturally;

[0038] ②Interface treatment: Sandblast and frost the interface of titanium plate, pure aluminum plate and stainless steel plate to be combined to clean the residual oxide layer on the surface of the three plates. The depth of grinding is 0.2-0.6mm. The aluminum plate and the stainless steel plate are rinsed clean, and finally dried at a temperature of 100-200°C for 5-10 minutes;

[0039]③Heating treatment: After aligning the composite interfaces of the titanium plate, pure aluminum plate,...

Embodiment 2

[0045] Example 2: A titanium-aluminum-stainless steel clad plate with a thickness of 5.0 mm as a hot-rolled composite product.

[0046] Among them: the thickness of titanium plate is 1.0mm titanium plate, the thickness of aluminum plate is 5.0mm pure aluminum plate, the thickness of stainless steel plate is 316L stainless steel plate of 1.5mm, its actual operation process is basically the same as that of example 1, the difference is that the heating time is correspondingly increased by 5 -20 minutes, that is, 15-50 minutes, the reduction rate is 33% of the original total thickness of the composite plate, and finally the composite finished product is a titanium-aluminum-stainless steel composite plate with a thickness of 5.0 mm.

Embodiment 3

[0047] Embodiment 3: A titanium-aluminum-stainless steel clad plate with a thickness of 1.24mm is hot-rolled.

[0048] Among them: the imported titanium plate with a titanium plate thickness of 0.5mm, the 1050 pure aluminum plate with a thickness of 1.0mm, and the 304 stainless steel plate with a stainless steel plate thickness of 0.5mm. When riveting, two sets of plates are used to superimpose and complete hot rolling. There are six plates in total. The specific arrangement method is: stainless steel plate, aluminum plate, titanium plate, titanium plate, aluminum plate, stainless steel plate, and between the two titanium plates. A special anti-adhesive agent is added in between, the anti-adhesive agent can be magnesium oxide powder, the time of rolling and heating is adjusted according to the total thickness of the composite plate, the reduction rate is 38% of the original total thickness of the composite plate, and other parts The process is the same as in Example 1. Finally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap